Fine particle natural graphite synthesis process method and device

A technology of natural graphite and fine particles, applied in graphite, manufacturing tools, presses, etc., can solve the problems of backward technology and poor synthesis effect of devices, and achieve the effect of compact process structure, stable large scale graphite structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

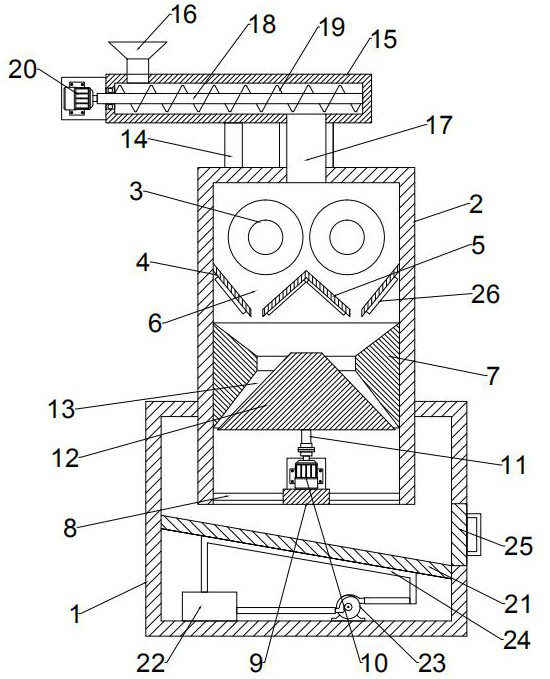

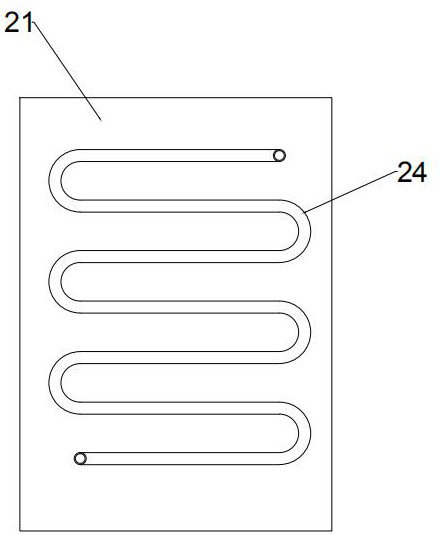

[0032] Embodiment: When in use, the fine flake graphite is transported into the material delivery channel 15 by the feed port 16, the servo motor 20 is started, and the driving end of the servo motor 20 drives the screw shaft 18 and the screw plate 19 to rotate, so that the graphite raw material is fed by the screw plate 19 is gradually pushed toward the discharge port, and finally the graphite raw material enters the extrusion box 2 evenly, and a pair of extrusion rollers 3 rotate mutually to carry out preliminary extrusion molding of the graphite raw material, and the graphite raw material continues to fall to the center after one extrusion On the guide plate 5 and the side guide plate 4, at this time, the electric heating rod 26 can heat up the graphite raw material to facilitate subsequent molding. 7, start the driving motor 10, the driving motor 10 drives the rotating shaft 11 and the extrusion head 12 to rotate, and the graphite raw material extruded once is extruded twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com