Wastewater collecting device of chemical industry equipment and working method of device

A waste water collection and equipment technology, applied in chemical instruments and methods, oxidized water/sewage treatment, multi-stage water treatment, etc., can solve problems such as inconvenient cleaning, single function, and affecting the speed of waste water collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

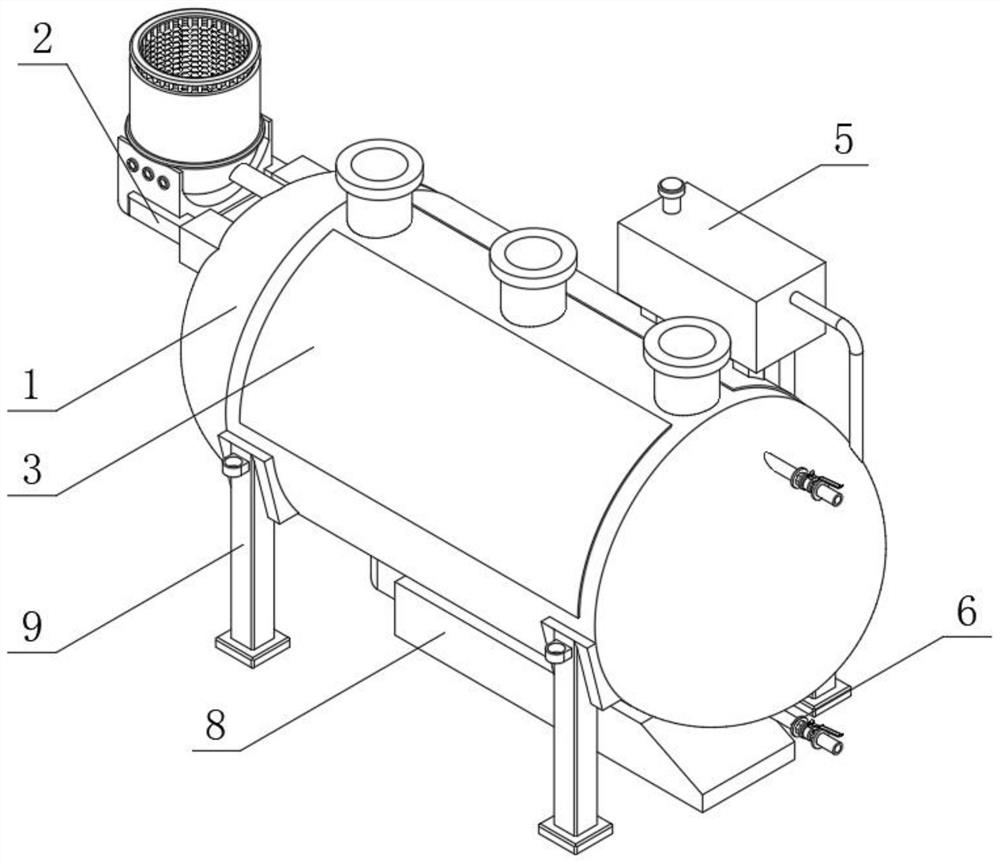

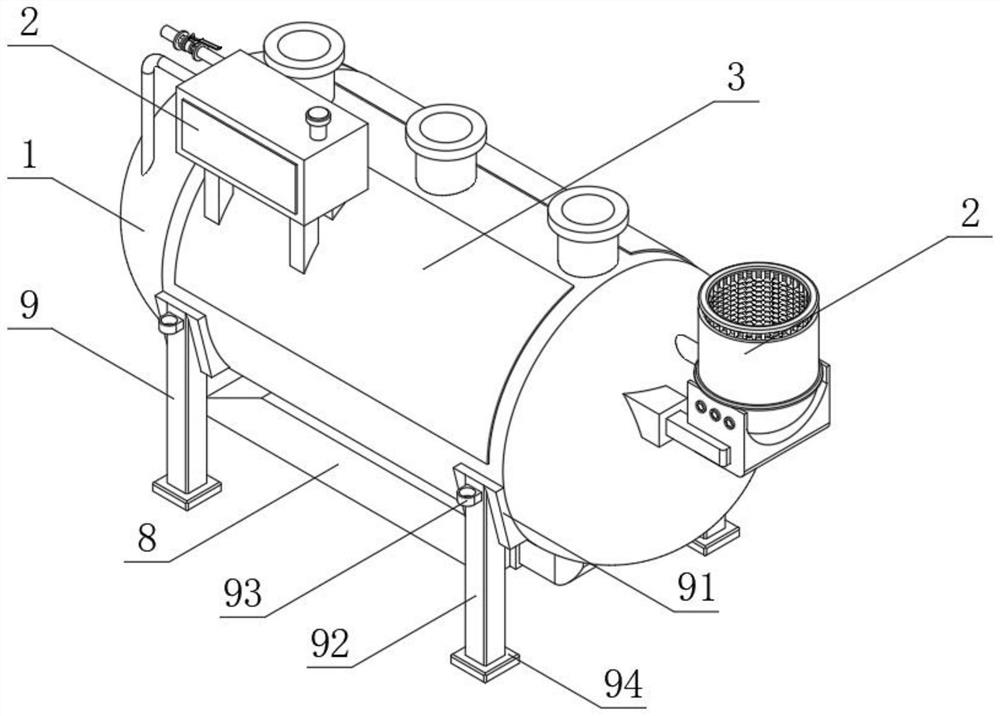

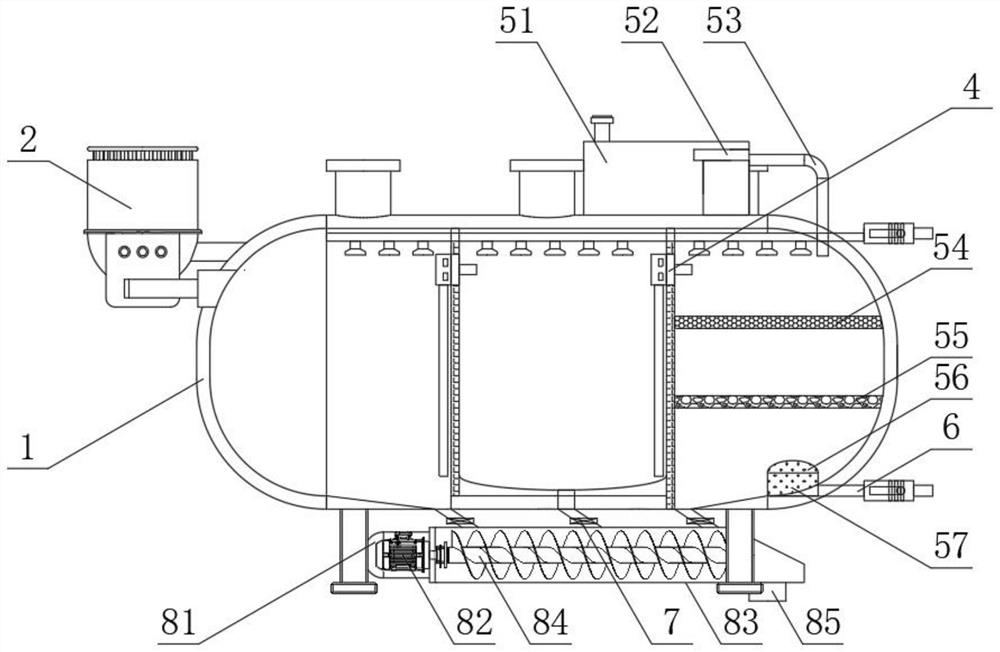

[0024] As an embodiment of the present invention, the primary filter assembly 2 includes a mounting arm frame 21, a connecting base plate 22, a bracket 23, a primary filter cartridge 24, a primary filter wire mesh 25 and a water inlet pipe 26, and the mounting arm frame 21 is fixedly installed by welding On both sides of the side end face of the water storage tank 1, the top end face of the mounting arm frame 21 is fixedly installed with a connecting base plate 22 by bolts, and the top of the connecting base plate 22 is provided with a primary filter cartridge 24, and the outer wall of the primary filter cartridge 24 is fixedly installed with Bracket 23, and bracket 23 is fixedly connected with connection base plate 22 by screw, and the inner wall of primary filter cartridge 24 is fitted with primary filter wire mesh 25, and the bottom of one side of primary filter cartridge 24 is plugged with water inlet pipe 26, and One end of the water pipe 26 passes through the primary filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com