Collection type aluminum profile cutting process

A cutting process, aluminum profile technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of affecting waste collection, the inability of waste collection equipment to be realized, and the clogging of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

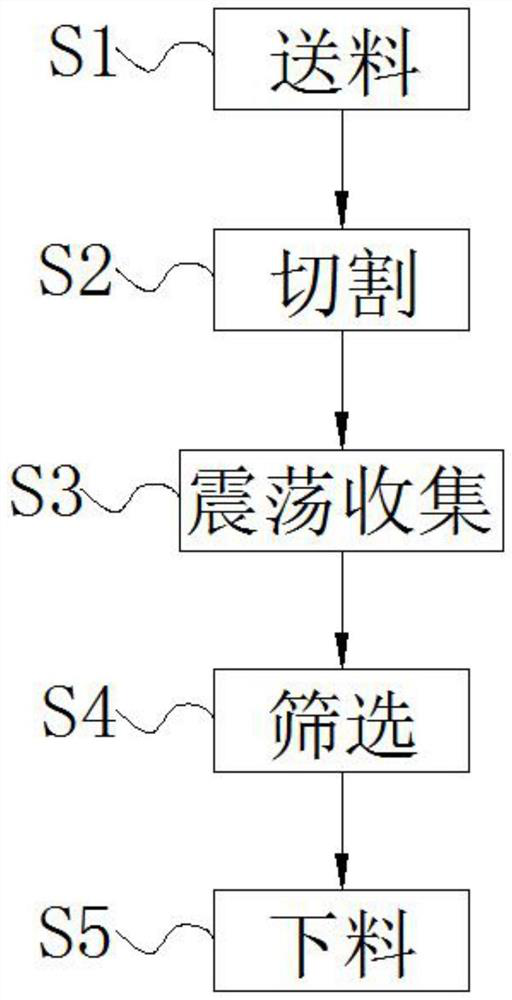

[0026] S1. Feeding: First, the aluminum profile to be cut is transported to the workbench of the cutting station through the conveying equipment, and the aluminum profile to be cut is clamped by the clamp on the workbench;

[0027] S2. Cutting: Start the cutting equipment to lower the knife, and cut the aluminum profile clamped on the workbench according to the required cutting requirements;

[0028] S3. Oscillation collection: the waste slag generated by cutting in step S2 will fall into the collection bucket. At this time, start the vibration mechanism to push the top of the collection bucket, and then cooperate with the buffer reset component to realize the reciprocating vibration treatment of the collection bucket. The vibration mechanism includes a vibration motor, The oscillating cam and the arc-shaped top block adapted to the oscillating cam, the oscillating motor is fixedly installed inside the cutting equipment through a fixing piece, and the output shaft of the oscill...

Embodiment 2

[0032] S1. Feeding: First, the aluminum profile to be cut is transported to the workbench of the cutting station through the conveying equipment, and the aluminum profile to be cut is clamped by the clamp on the workbench;

[0033] S2. Cutting: Start the cutting equipment to lower the knife, and cut the aluminum profile clamped on the workbench according to the required cutting requirements;

[0034]S3. Oscillation collection: the waste slag generated by cutting in step S2 will fall into the collection bucket. At this time, start the vibration mechanism to push the top of the collection bucket, and then cooperate with the buffer reset component to realize the reciprocating vibration treatment of the collection bucket. The vibration mechanism includes a vibration motor, The oscillating cam and the arc-shaped top block adapted to the oscillating cam, the oscillating motor is fixedly installed inside the cutting equipment through a fixing piece, and the output shaft of the oscilla...

Embodiment 3

[0038] S1. Feeding: First, the aluminum profile to be cut is transported to the workbench of the cutting station through the conveying equipment, and the aluminum profile to be cut is clamped by the clamp on the workbench;

[0039] S2. Cutting: Start the cutting equipment to lower the knife, and cut the aluminum profile clamped on the workbench according to the required cutting requirements;

[0040] S3. Oscillation collection: the waste slag generated by cutting in step S2 will fall into the collection bucket. At this time, start the vibration mechanism to push the top of the collection bucket, and then cooperate with the buffer reset component to realize the reciprocating vibration treatment of the collection bucket. The vibration mechanism includes a vibration motor, The oscillating cam and the arc-shaped top block adapted to the oscillating cam, the oscillating motor is fixedly installed inside the cutting equipment through a fixing piece, and the output shaft of the oscill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com