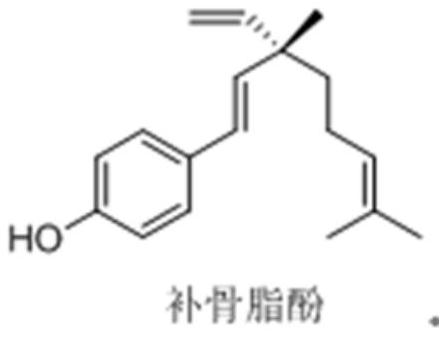

Green process for extracting high-purity bakuchiol

A bakuchiol, green technology technology, applied in the field of green technology, can solve the problems of large solvent consumption, cumbersome process steps, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 bakuchiol

[0039] Proceed as follows:

[0040](1) Supercritical extraction: 5 kg of dried psoraleae, crushed to 80 mesh, put into an extraction kettle, and extracted with supercritical carbon dioxide; the extraction temperature is 40°C, the extraction pressure is 30Mpa, and the flow rate of carbon dioxide is 20L / h, After equilibrating for 20 minutes, flow extraction; extraction for 2 hours; the pressures of the analysis kettles A and B were 8Mpa and 6Mpa, and the temperatures were 45°C and 40°C, respectively, and analyzed to obtain 780mL of yellow oily liquid containing bakuchiol.

[0041] (2) Preliminary separation: the oily liquid was dissolved with 8000 mL of petroleum ether, filtered to remove highly polar insoluble matter, and the filtrate was concentrated under reduced pressure to obtain 418 g of bakuchiol crude extract.

[0042] (3) Purification by column chromatography: load the crude bakuchiol extract onto a silica gel chromato...

Embodiment 2

[0043] The preparation of embodiment 2 bakuchiol

[0044] Proceed as follows:

[0045] (1) Supercritical extraction: 5 kg of dried psoraleae, crushed to 100 mesh, put into an extraction kettle, and extracted with supercritical carbon dioxide; the extraction temperature is 45°C, the extraction pressure is 30Mpa, and the flow rate of carbon dioxide is 20L / h, After equilibrating for 20 minutes, flow extraction; extraction for 3 hours; the pressures of the analysis kettles A and B were 10Mpa and 8Mpa, respectively, and the temperatures were 30°C and 25°C respectively, and the analysis was carried out to obtain 760mL of oily liquid containing bakuchiol.

[0046] (2) Preliminary separation: the oily liquid was dissolved with 5000 mL of petroleum ether, filtered to remove large polar insoluble matter, and the filtrate was concentrated under reduced pressure to obtain 433 g of bakuchiol crude extract.

[0047] (3) Purification by column chromatography: load the crude bakuchiol extrac...

Embodiment 3

[0048] The preparation of embodiment 3 bakuchiol

[0049] Proceed as follows:

[0050] (1) Supercritical extraction: dry 5 kg of psoraleae, crush it to 40 mesh, put it in an extraction kettle, and extract with supercritical carbon dioxide; extraction temperature is 45°C, extraction pressure is 30Mpa, flow rate of carbon dioxide is 25L / h, and balance for 20 minutes After flow extraction; extraction for 2 hours; the pressures of the analysis kettles A and B were 15Mpa and 10Mpa respectively, and the temperatures were 50°C and 30°C respectively, and the analysis was carried out to obtain 740mL of oily liquid containing bakuchiol.

[0051] (2) Preliminary separation: the oily liquid was dissolved with 9000 mL of n-hexane, filtered to remove the large polar insoluble matter, and the filtrate was concentrated under reduced pressure to obtain 420 g of bakuchiol crude extract.

[0052] (3) Purification by column chromatography: load the bakuchiol crude extract on an alumina chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com