Baijiu brewing fermentation device

A fermentation device and liquor technology, which is applied in the field of liquor brewing, can solve the problems of staff burns, high labor intensity, and low work efficiency, and achieve the effect of improving the degree of mixing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

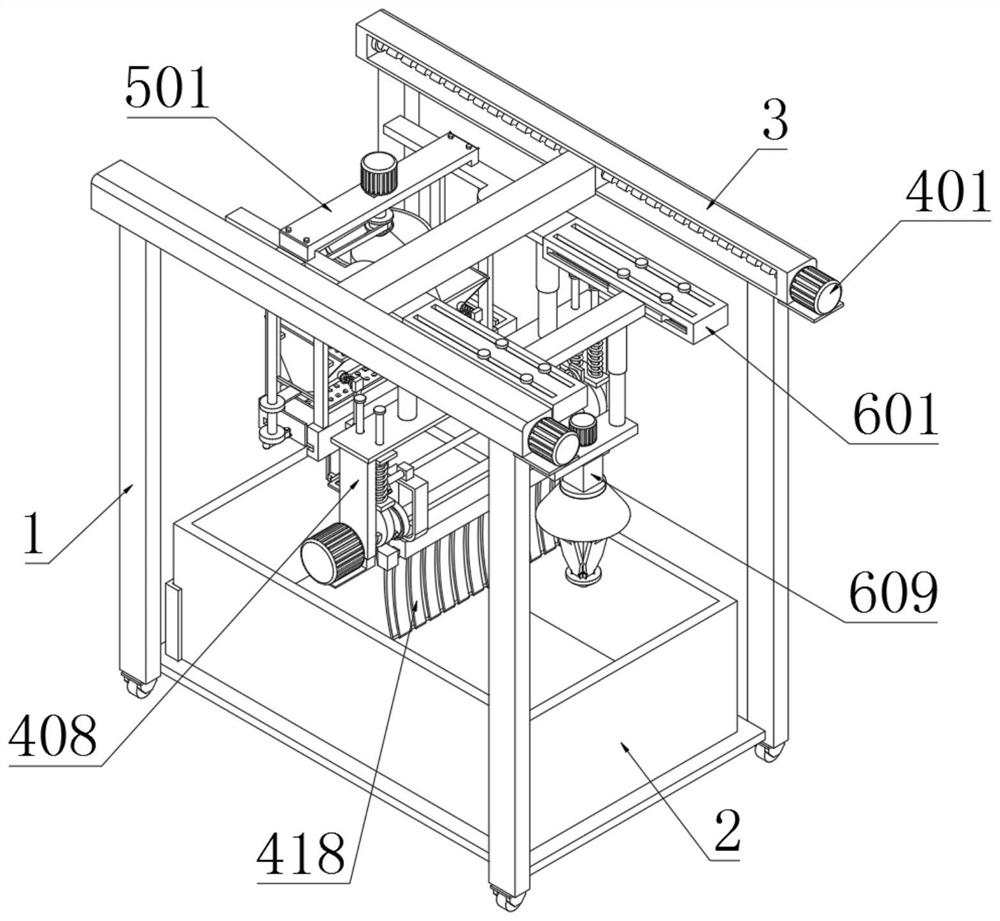

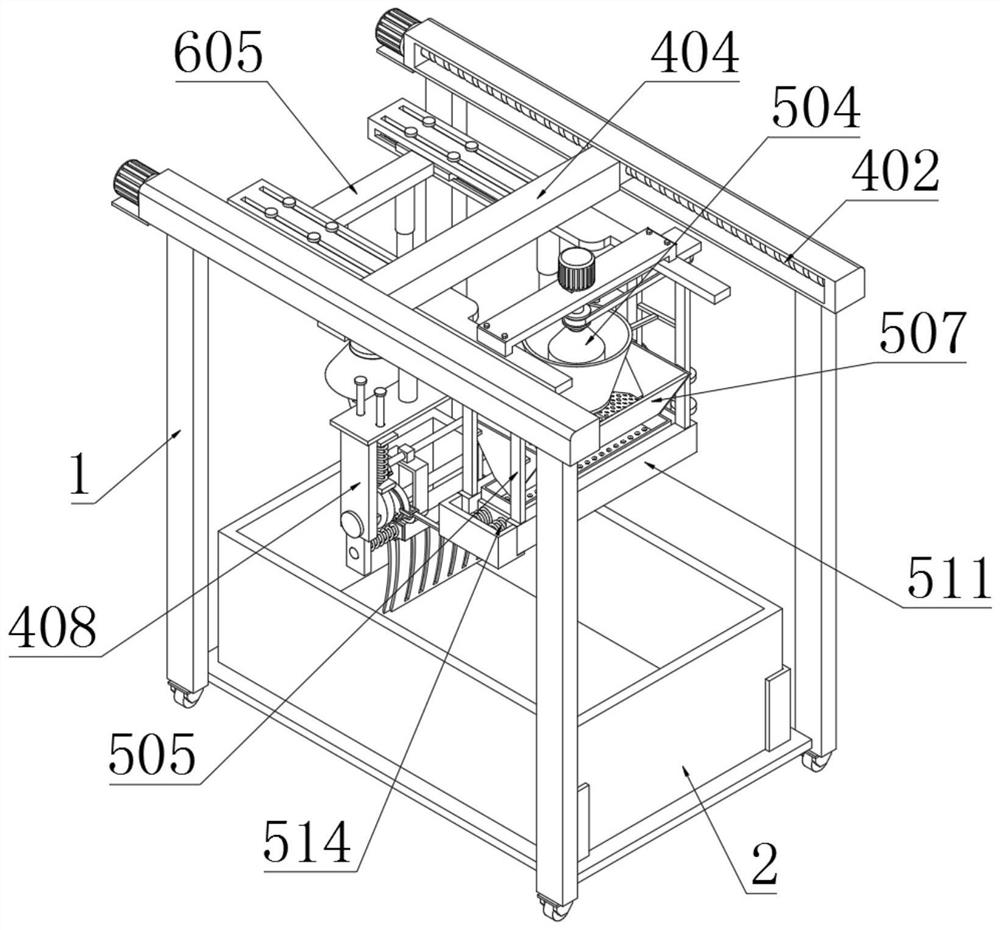

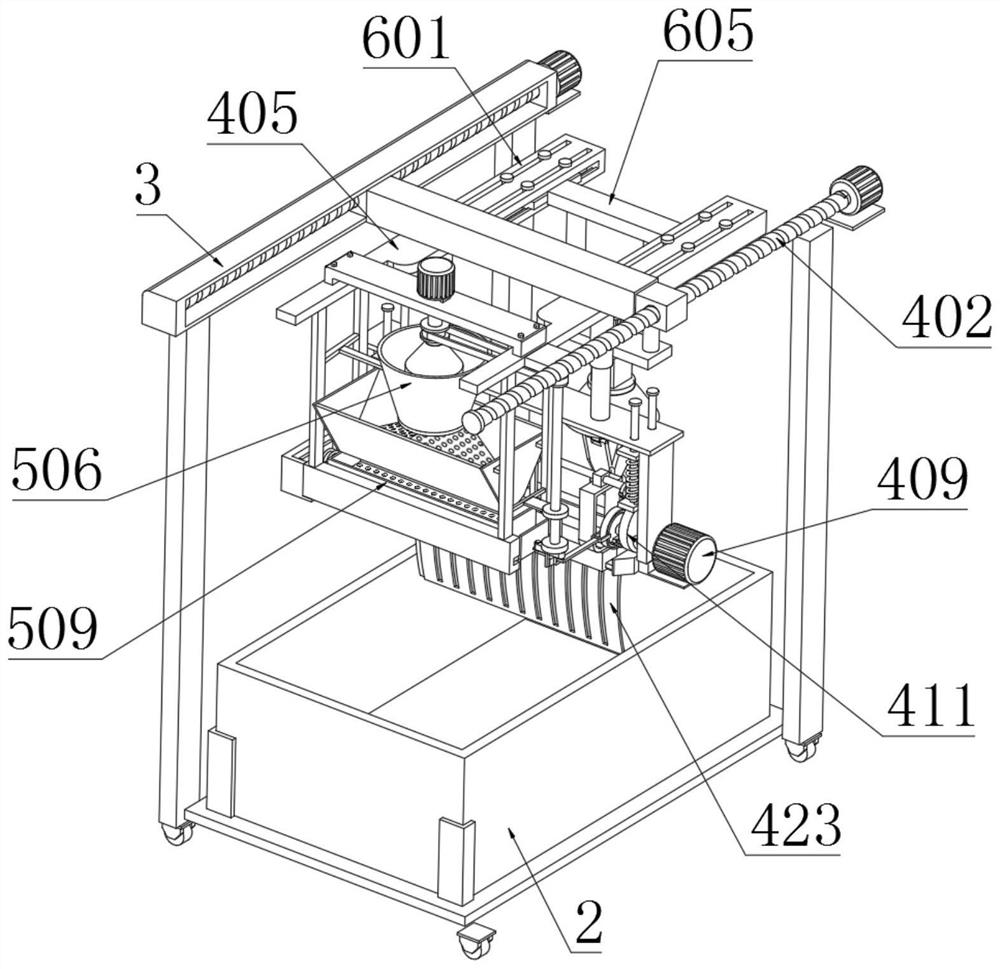

[0037] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a liquor brewing and fermentation device, comprising a frame 1, a fermentation box 2 is placed at the bottom of the frame 1, a beam 3 is symmetrically and fixedly installed on the top of the frame 1, and a beam 3 is installed in the middle of the frame 1 There is a convenient turning mechanism 4 for grain, and the front and rear turning plates 418 and 423 are used to reciprocate up and down and turn backwards to facilitate mixing of grain and koji;

[0038] Grain convenient turning mechanism 4 comprises driving motor 401, screw mandrel 402, movable block 403, cross bar 404, connecting plate 405, hydraulic telescopic rod 406, transverse plate 407, mounting frame 408, reduction motor 409, rotating rod 410, eccentric wheel 411 , extrusion plate 412, movable column 413, extrusion spring 414, fixed rod 415, connecting frame 416, connecting rod 417, front turning plate 418, front slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com