Noise reduction device for spliced warp knitting machine

A warp knitting machine and splicing technology, which is applied in warp knitting, mechanical equipment, textile/flexible product manufacturing, etc., can solve problems such as unfavorable health of workers, lack of noise reduction devices, and erosion of workers, so as to reduce noise Harm to the human body, convenient shock absorption and noise reduction, and the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

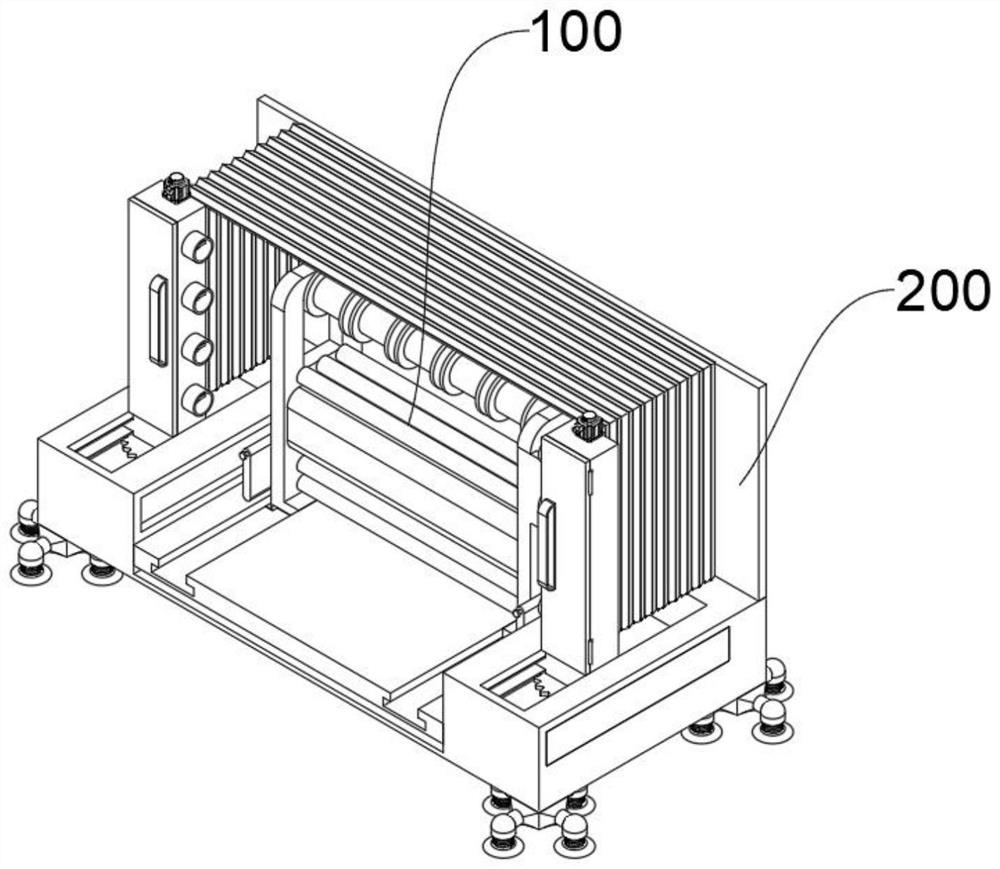

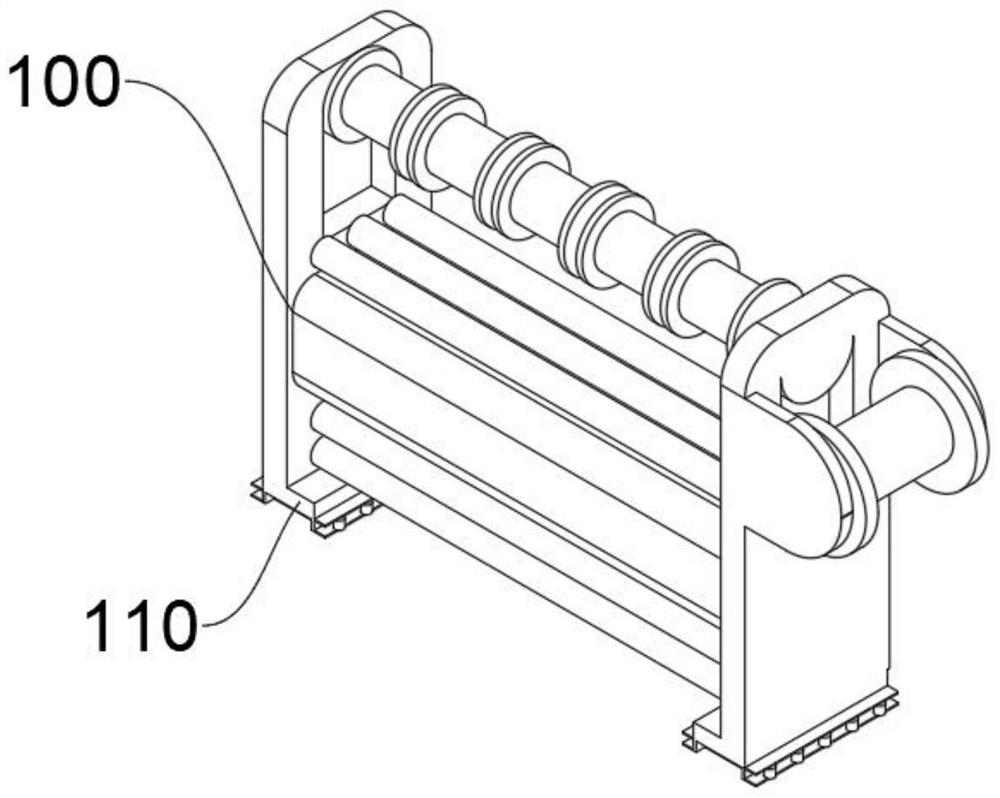

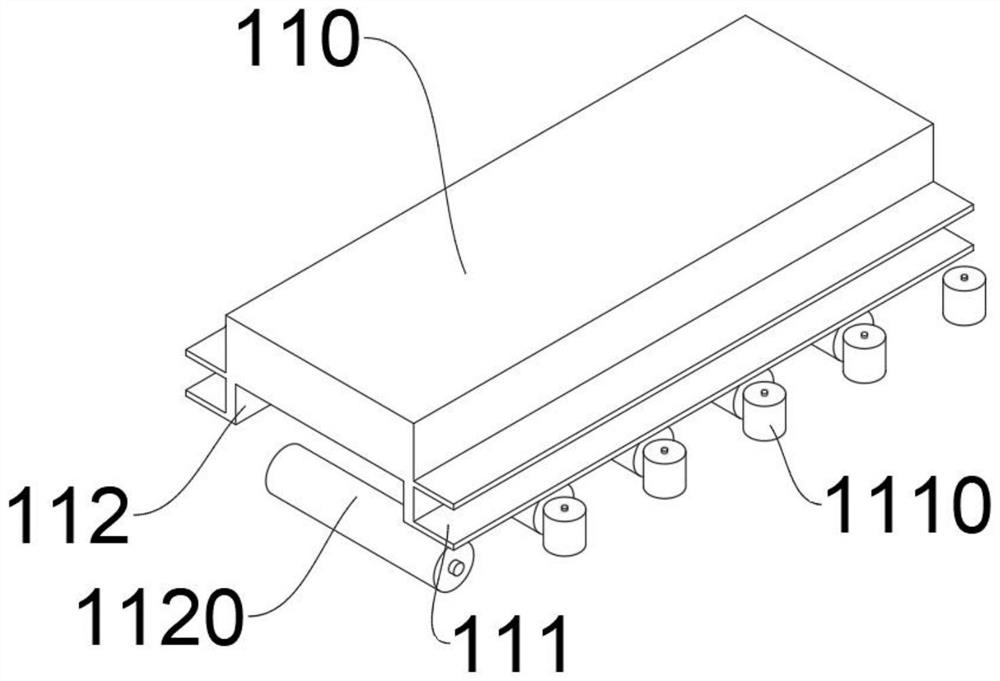

[0051] see Figure 1-Figure 15 As shown, this embodiment provides a splicing type warp knitting machine noise reduction device, including the warp knitting machine body 100 and the protective noise reduction mechanism 200 outside the warp knitting machine body 100, and the bottom of the warp knitting machine body 100 is provided with two symmetrical The moving block 110, the protective noise reduction mechanism 200 at least includes:

[0052] Support plate 210, the cross section of support plate 210 is "U" shape, the warp knitting machine body 100 is located at the inner center of support plate 210, and the top of support plate 210 near the edge is provided with two symmetrical chute 211, and the inner wall of chute 211 There are two symmetrical power plates 212, the inner surface of the power plate 212 near the bottom is provided with a rack 2122, and the bottom of the support plate 210 is provided with a support device 215 near the four corners. The support device 215 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com