Wiping cloth manufacturing method and wiping cloth

A manufacturing method and wiping cloth technology, applied in the field of wiping cloth and wiping cloth manufacturing, can solve the problems of difficulty in accurately controlling the amount of liquid carried, inconvenient to carry liquid detergent, difficult to control the amount of use, etc., so as to avoid the loss of finishing liquid and avoid finishing Liquid splash, avoid uneven finishing and waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

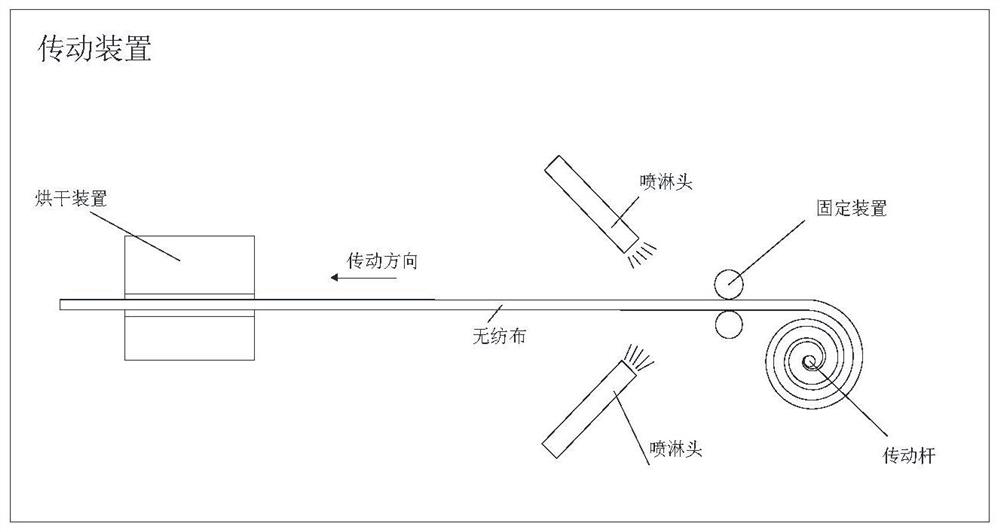

Method used

Image

Examples

Embodiment 1

[0025] A kind of wiping cloth manufacturing method, the base cloth of described wiping cloth is non-woven fabric, and its manufacturing process comprises the following steps:

[0026] A prepares a non-woven fabric, the non-woven base fabric is a three-layer structure, including a surface layer made of two layers of thermosetting fibers and a water-absorbing layer between the two surface layers, the material of the surface layer is polyester fiber, and the water-absorbing layer The material of the layer is viscose fiber, the non-woven fabric is formed into a net by wet method, and is cured and dried by spunlace process;

[0027] B prepares wipe cloth finishing agent, and this finishing agent is cleaning agent, and its composition comprises 20 parts of dodecylbenzenesulfonated isopropylamine salt, 10 parts of isomeric tridecyl alcohol polyoxyethylene ether, 5 parts of AEO-9, 2 parts Lauryl glucoside and 0.2 parts of coconut oil, the rest is deionized water. The configuration pr...

Embodiment 2

[0032] A kind of wiping cloth manufacturing method, the base cloth of described wiping cloth is non-woven fabric, and its manufacturing process comprises the following steps:

[0033] A prepares a non-woven fabric, the non-woven base fabric is a four-layer structure, including two layers of surface layers made of thermosetting fibers and two layers of water-absorbing layers between the two surface layers, the material of the surface layer is polyester fiber, the water-absorbent The layer material is viscose + wood pulp fiber, the non-woven fabric is formed into a web by wet method, and then cured and dried by spunlace process;

[0034]B prepares wipe cloth finishing agent, and this finishing agent is cleaning agent, and its composition comprises 25 parts of dodecylbenzene sulfonated isopropylamine salts, 10 parts of isomeric tridecyl alcohol polyoxyethylene ethers, 10 parts of AEO-9, 5 parts Lauryl glucoside and 0.5 parts of coconut oil, the rest is deionized water. The confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com