Washing machine dewatering control method and washing machine

A control method and technology for washing machines, which can be applied to control devices of washing machines, washing devices, textiles and paper making, etc., can solve problems such as clothing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

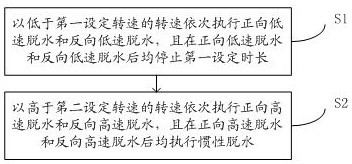

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, suitable for after the washing stage

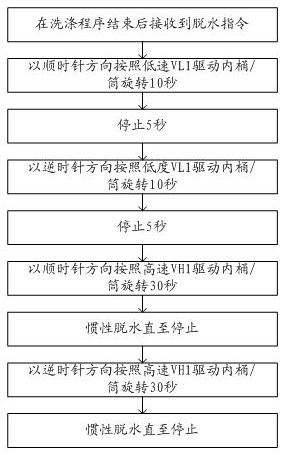

[0042] Specific as figure 2 Shown:

[0043] 1. The dehydration command is received after the washing program is finished.

[0044] After the washing process is over, the detergent and foam in the clothes are discharged by dehydration, so that the rinsing stage can be rinsed more thoroughly.

[0045] 2. The inner barrel / drum is controlled by the motor to enter the low-speed intermittent dehydration stage; the second setting time is 10 seconds for forward and reverse rotation; the first setting time for stopping after forward rotation and reverse rotation is 5 seconds.

[0046] a. Drive the inner barrel / barrel to rotate clockwise at low speed VL1 for 10 seconds;

[0047] b. Stop for 5 seconds;

[0048]c. Drive the inner barrel / barrel to rotate for 10 seconds in the counterclockwise direction according to the low level VL1;

[0049] d. Stop for 5 seconds.

[0050] Spin in forward and reverse directions at low spee...

Embodiment 3

[0075] Embodiment 3, suitable for the dehydration stage of the washing machine

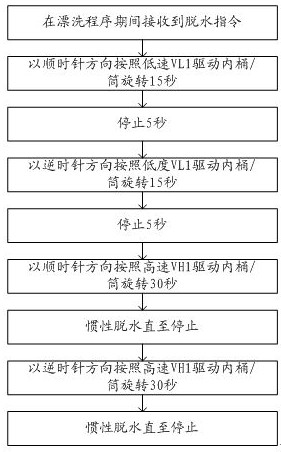

[0076] Specific as Figure 4 Shown:

[0077] 1. After the washing program and rinsing program are finished, the dehydration command is received.

[0078] This embodiment is applicable to the dehydration control of the washing machine after washing and rinsing.

[0079] 2. The inner barrel / drum is controlled by the motor to enter the low-speed intermittent dehydration stage; the forward and reverse rotation durations are both the second set duration of 10 seconds; the first preset duration of forward and reverse rotation and stop is 5 seconds.

[0080] a. Drive the inner barrel / barrel to rotate clockwise at low speed VL1 for 10 seconds;

[0081] b. Stop for 5 seconds;

[0082] c. Drive the inner barrel / barrel to rotate for 10 seconds in the counterclockwise direction according to the low level VL1;

[0083] d. Stop for 5 seconds;

[0084] e. Repeat step a to step d for the first set number of...

Embodiment 4

[0092] Embodiment 4, suitable for the dehydration stage of the washing machine

[0093] Specific as Figure 5 Shown:

[0094] 1. After the washing program and rinsing program are finished, the dehydration command is received.

[0095] This embodiment is applicable to the dehydration control of the washing machine after washing and rinsing.

[0096] 2. The inner barrel / drum is controlled by the motor to enter the low-speed intermittent dehydration stage; the forward and reverse rotation durations are both the second set duration of 10 seconds; the first preset duration of forward and reverse rotation and stop is 5 seconds.

[0097] a. Drive the inner barrel / barrel to rotate clockwise at low speed VL1 for 10 seconds;

[0098] b. Stop for 5 seconds;

[0099] c. Drive the inner barrel / barrel to rotate for 10 seconds in the counterclockwise direction according to the low level VL1;

[0100] d. Stop for 5 seconds;

[0101] e. Repeat step a to step d for the first set number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com