Rectangular steel pipe-corrugated steel plate composite wall steel coupling beam coupled wall

A technology of rectangular steel pipes and combined walls, which is applied to walls, residential buildings, building components, etc. It can solve the problems of difficult construction, large area of fireproof coating of shear walls, and large amount of welding on site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

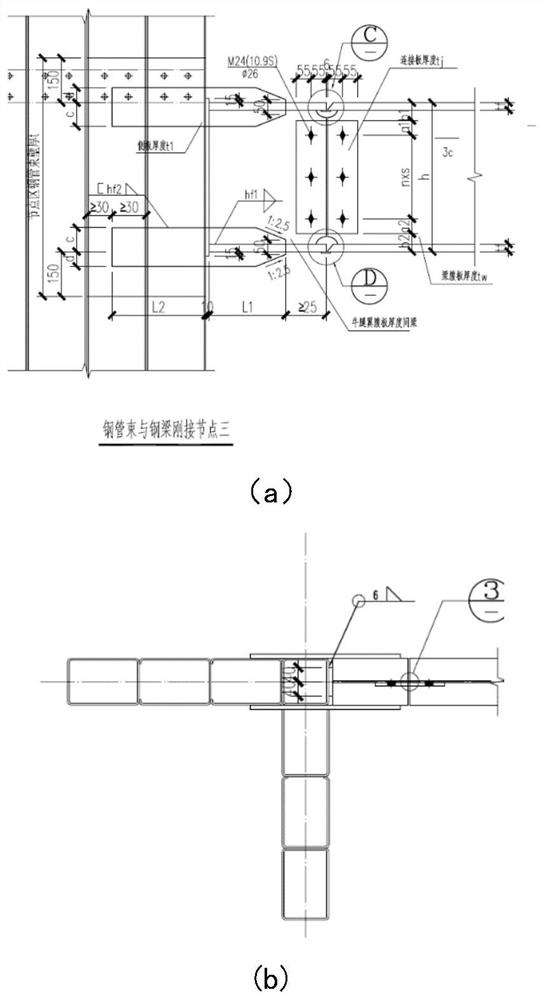

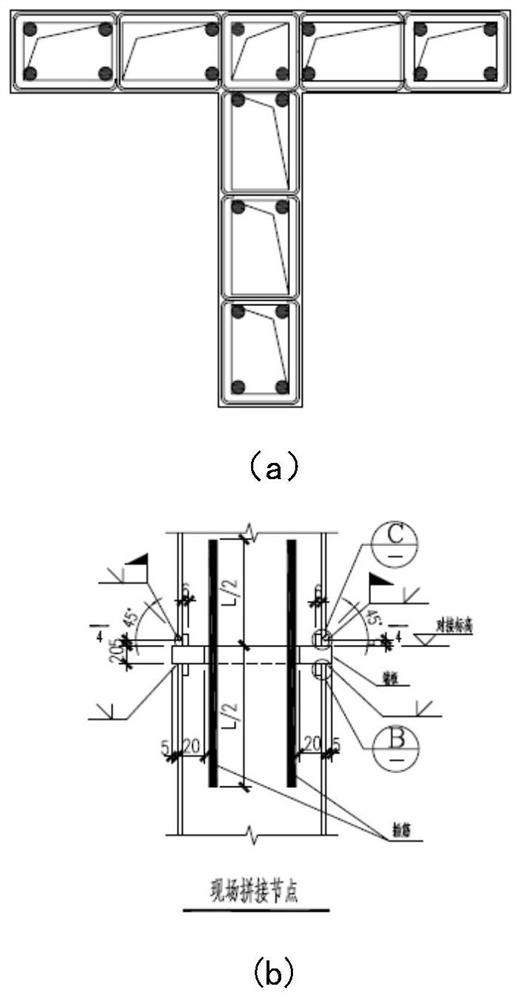

[0074] A corrugated steel composite wall structure system suitable for steel structure residences, characterized in that, the principle: design a new type of corrugated steel composite wall as a side-resistant component unit, by adopting the design idea of separating the side-resistant and load-bearing components of the structural system, according to the building Functional requirements, arrange sufficient and appropriate cross-sectional shapes at appropriate locations Corrugated steel composite wall anti-side member (referred to as Anti-side member elements, Figure 4 ); the anti-side member units are connected by hinged steel beams in the horizontal direction, and the anti-side member units are connected by joints in the vertical direction, thus forming a new structural system. At the same time, the overall analysis of the new structural system is carried out, and the corrugated steel plate composite wall and hinged steel beams are designed according to the results...

Embodiment 2

[0091] Based on Embodiment 1, a set of design methods for realizing the structural system is further disclosed.

[0092] Such as Figure 10 As shown, the design method of the corrugated steel composite wall structure system includes the following steps in sequence:

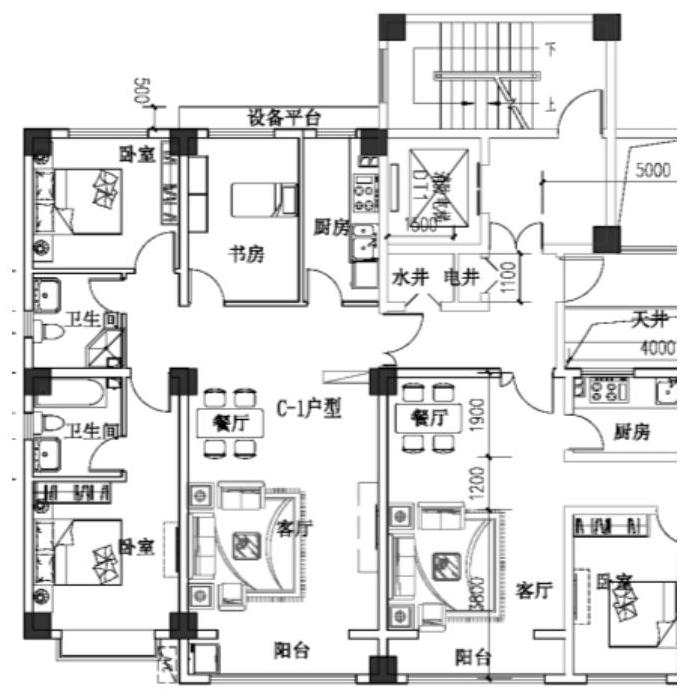

[0093] S1 First, obtain the possible arrangement positions of corrugated steel plate composite walls and hinged steel beams according to the building layout drawings;

[0094] According to the specific building layout, select side-resistant member units with different cross-sections such as in-line, L-shaped, T-shaped, Z-shaped, and cross-shaped, which are suitable for actual needs. The walls are connected by hinged steel beams (6-1) .

[0095] When conditions permit, energy-dissipating combined limb walls (cylinders) (5) with greater lateral stiffness can be arranged in conjunction with stairwells, elevators, etc., and energy-dissipating connecting beams (6-2) can be used to connect. When an earthquake occur...

Embodiment 3

[0101] Based on the design operation method of Embodiment 2, this embodiment envisages the development of a set of application software for designing and outputting construction system cases.

[0102] For example and not limitation, the application software includes building databases, including prefabricated three types of splicing structure models, including prefabricated cross-sections with different straight, L-shaped, T-shaped, Z-shaped, and cross-shaped anti-side member unit modules; application software algorithms The process is:

[0103] Step 1. Input the electronic drawings of the building layout, and obtain the possible arrangement positions of corrugated steel plate composite walls and hinged steel beams in the plan space, and provide step 2 after screening;

[0104] Step 2. Model and analyze the structure

[0105] In the analysis model, the corrugated steel plate composite wall is analyzed as a square steel pipe-corrugated steel plate-concrete composite structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com