Feather-shaped directional soft rock tunnel advanced grouting pre-reinforcing structure and method

An advance grouting and pre-reinforcement technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of limited tunnel face space, difficult construction, and difficulty in positioning construction equipment, so as to save grouting materials and The effect of construction workload, improvement of economic and social benefits, reproducibility and generalizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with an embodiment of a subway tunnel in Beijing, but the present invention is not limited to the following examples.

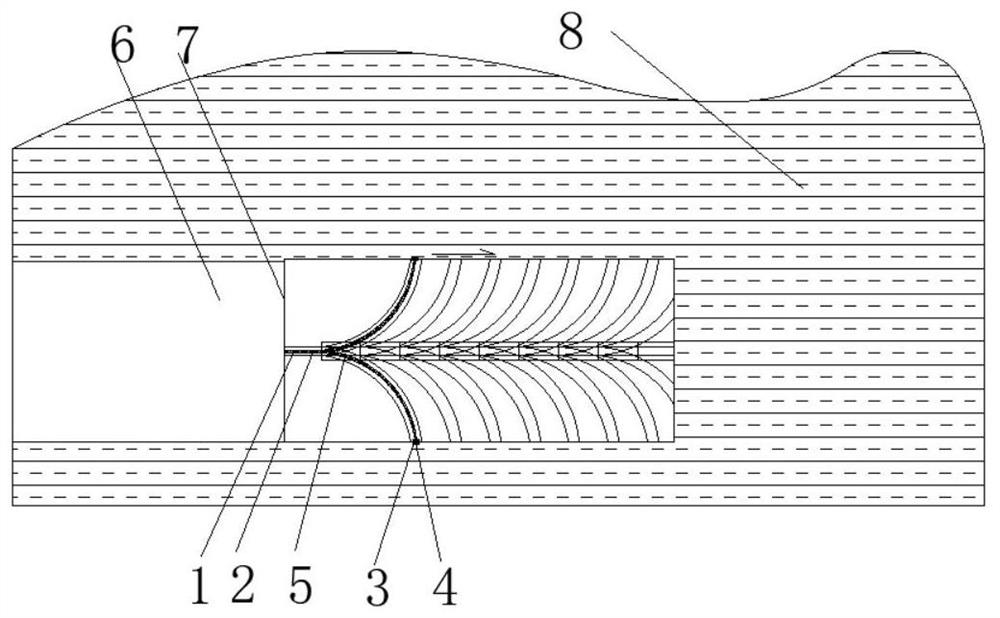

[0047] A subway tunnel in Beijing is interbedded with silty clay and sand layers 0-15 meters below the ground, and the groundwater is abundant. The groundwater type is a mixed form of phreatic water and confined water. The subway tunnel section is 100m 2 Left and right, the tunnel construction method is the CRD method. When the tunnel (6) is constructed to the tunnel face (7) in the soft rock formation (8), the surrounding rock in front of the tunnel face is pre-reinforced by grouting.

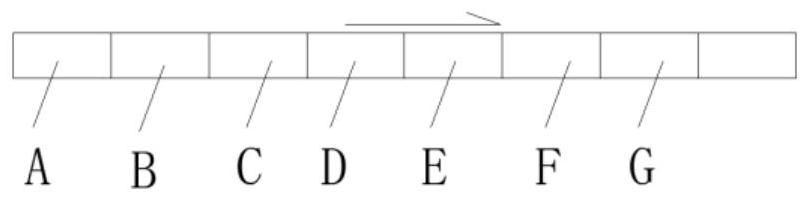

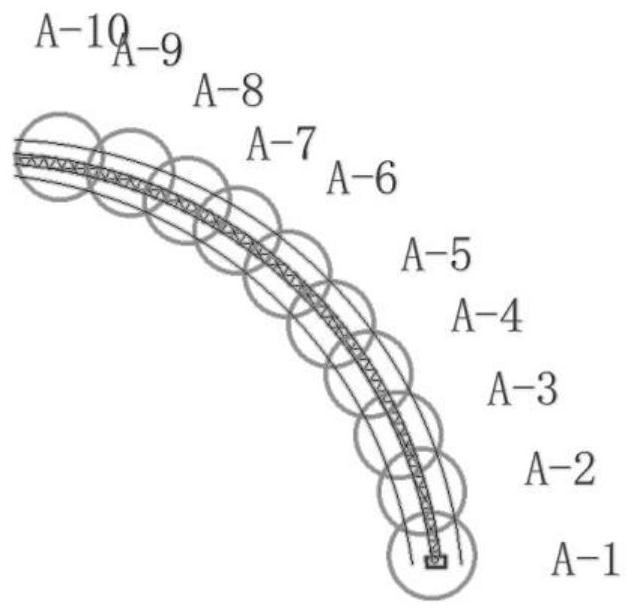

[0048] The first step in the implementation of the present invention is to put the drilling rig in place, carry out construction lofting according to the tunnel design drawing, and determine the position of the grouting hole. The drilling position is arranged at the center of the tunnel face in princi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com