Dry type oil-free screw compressor

A compressor and oil screw technology, applied in the field of compressors, can solve the problems of increasing installation space, large installation space, lubricating oil ingress, etc., to prevent air pressure from being too large, occupying small installation space, and preventing leakage to the gas seal effect at

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

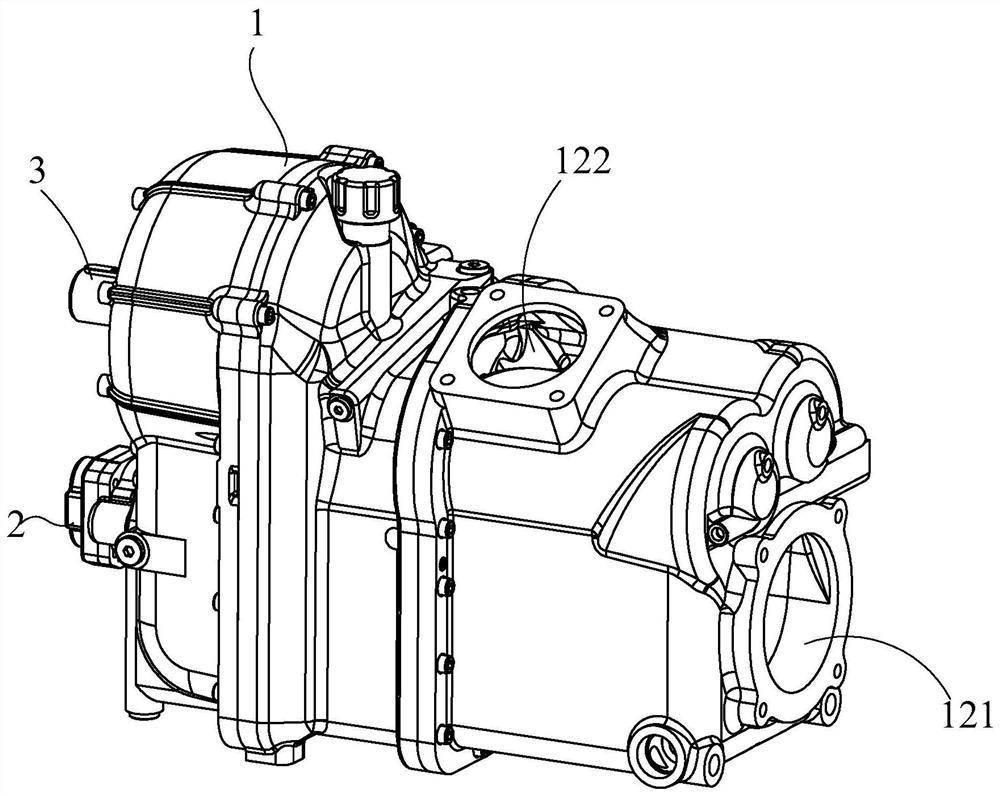

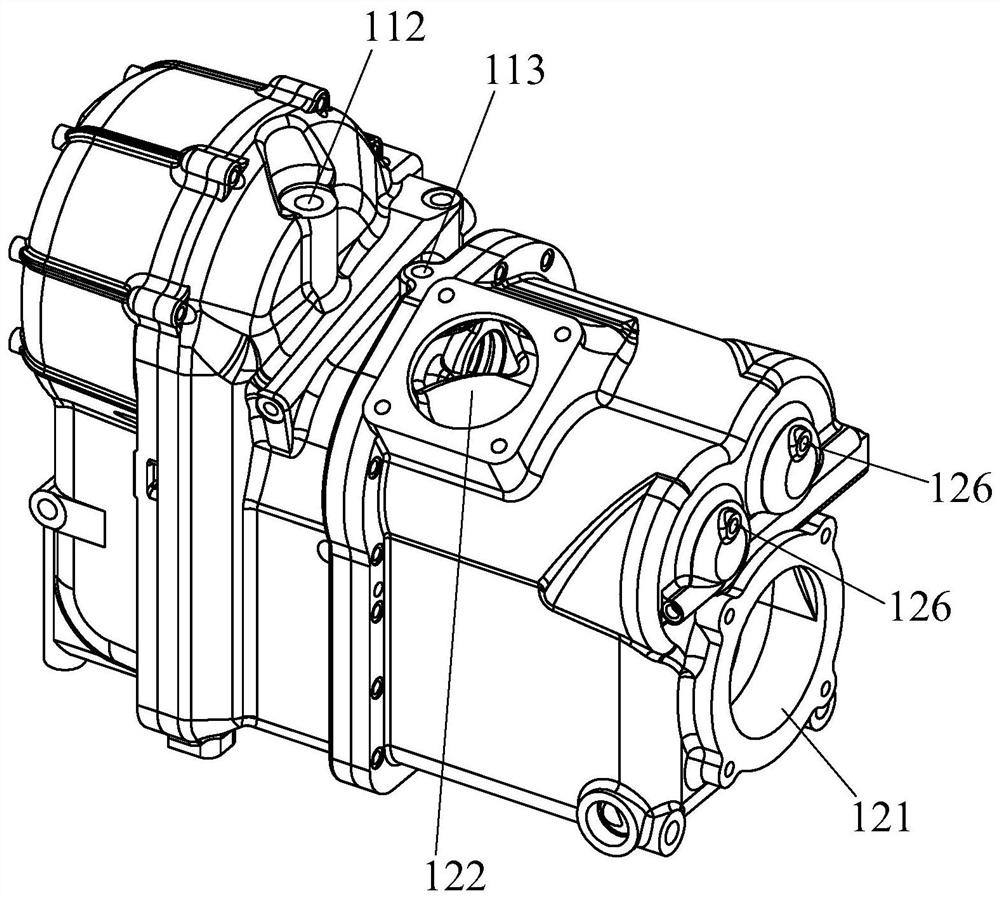

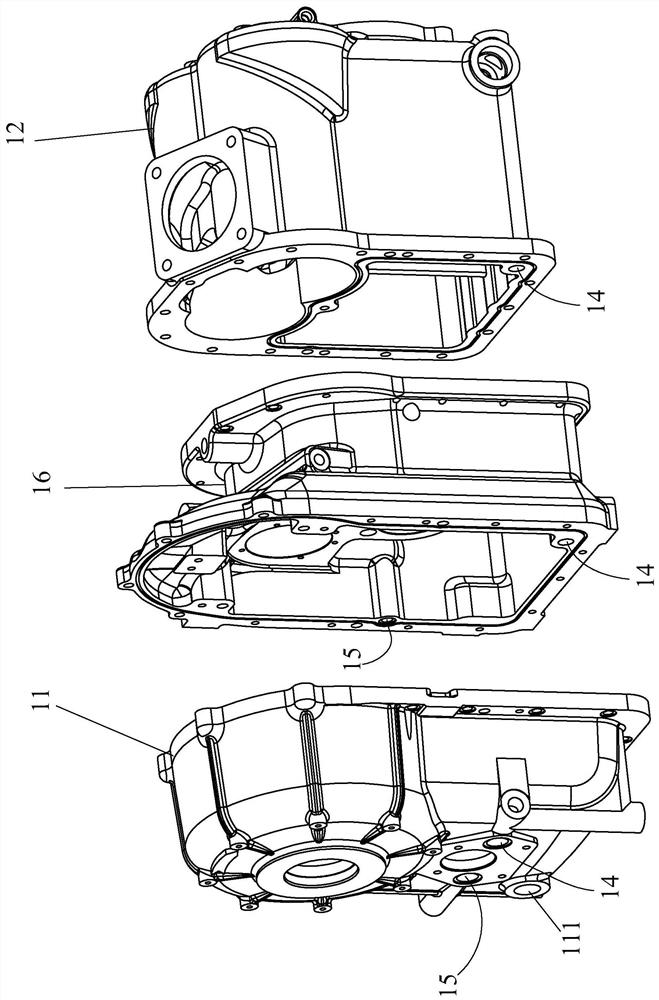

[0034] see Figure 1 to Figure 12 .

[0035] This embodiment discloses a dry oil-free screw compressor, which includes a casing 1 , an oil pump 2 , a main drive shaft 3 , a gear transmission assembly and a male-female screw transmission pair installed in the casing 1 . The main drive shaft 3 drives the male screw drive pair through the gear drive assembly; the male screw drive pair includes a pair of male screw rods 51 and female screw rods 52 that mesh with each other and are arranged in parallel. The air side seal assembly and the exhaust side seal assembly are provided with bearing assemblies.

[0036]In this embodiment, the gear transmission assembly includes a primary driving gear 41 , a primary driven gear 42 , a secondary driving gear 43 , a secondary driven gear 44 and a driven shaft 45 ; the driven shaft 45 is parallel to the main transmission shaft 3 Arrangement, the primary driven gear 42 and the secondary driving gear 43 are both mounted on the driven shaft 45, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com