Automatic replacing, cleaning and maintaining method and system for automatic transmission oil

An automatic gearbox and automatic replacement technology, which is applied in vehicle maintenance, engine viscosity, engine components, etc., can solve problems such as slow process, time-consuming, insufficient oil injection, and lack of personnel to provide oil change cleaning machine equipment, etc., to achieve strong accuracy , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

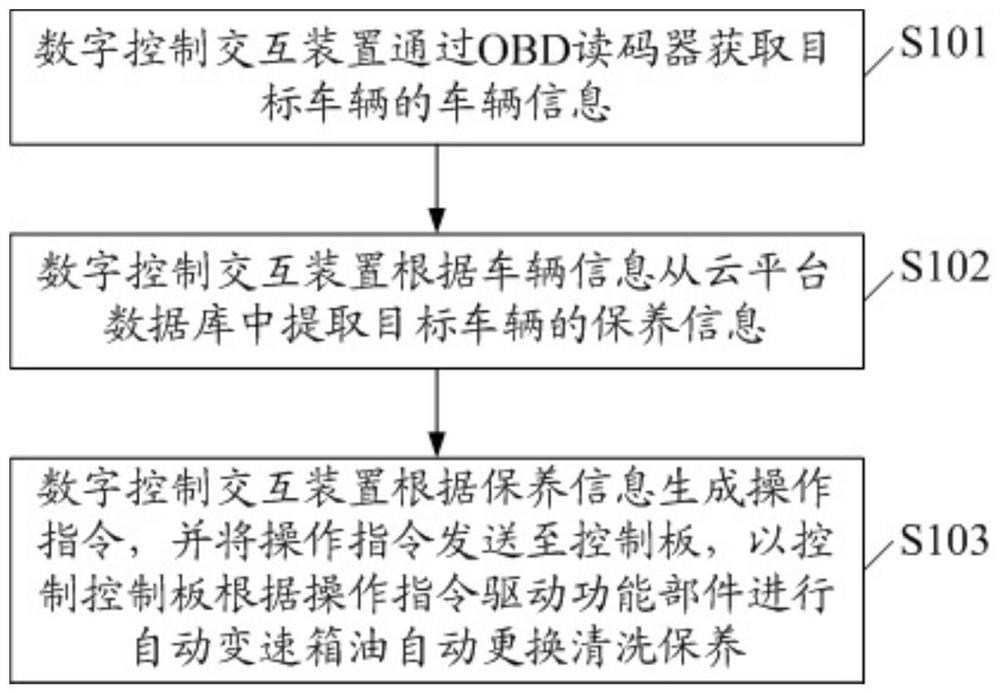

[0034] see figure 1 , figure 1 The flow chart of an embodiment of the automatic transmission oil automatic replacement, cleaning and maintenance method of the present invention is shown, including:

[0035] S101, the digital control interaction device obtains vehicle information of a target vehicle through an OBD code reader.

[0036] The digital control interaction device can be a fixed terminal touch screen digital control interaction device or a mobile tablet computer type digital control interaction device. Bluetooth or WIFI way to realize wireless communication.

[0037] Specifically, the step of obtaining the vehicle information of the target vehicle by the digital control interaction device through the OBD code reader includes:

[0038] (1) The OBD code...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com