Long-duration high-precision rheological test system for simulating deep geological complex conditions

A rheological test, long-duration technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve problems such as load reduction, inability to ensure constant load or stress, and liquid pressure drop. To achieve the effect of reliable measurement results and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

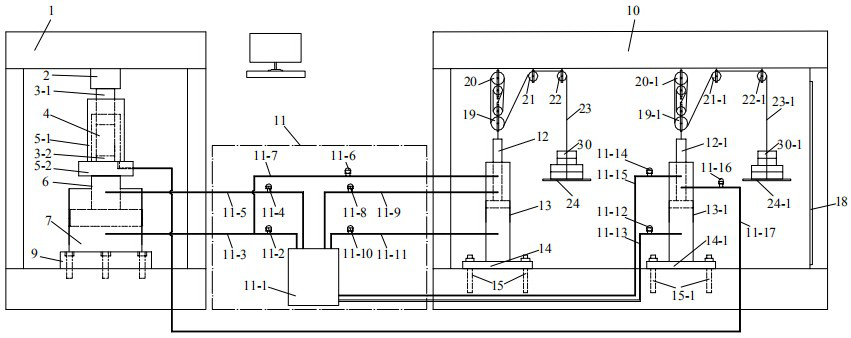

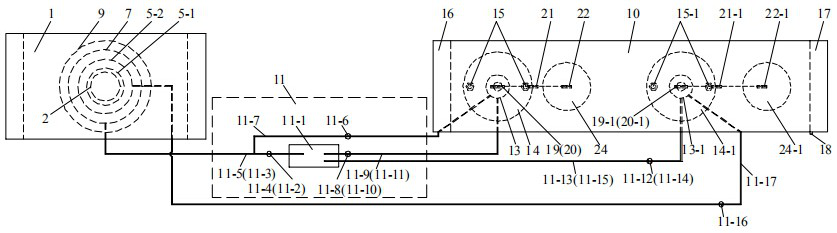

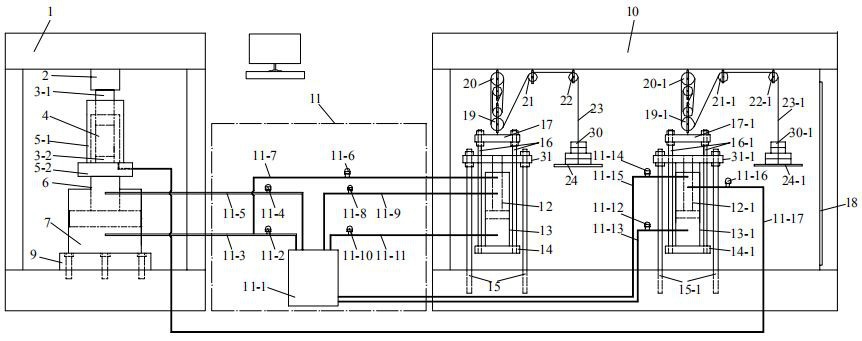

[0060] This embodiment provides a long-duration and high-precision rheological test system for simulating complex deep ground conditions. Specifically, the rheological test system is a triaxial compression rheological test system.

[0061] Such as Figure 1-Figure 4 As shown, the triaxial compression rheological test system includes interconnected sample installation components, a loading mechanism, and a hydraulic station module that is connected to the sample installation components and the loading mechanism for liquid supply;

[0062] The sample mounting assembly includes a mounting frame 1 and a load sensor 2 installed in the mounting frame 1 from top to bottom, a sample holding assembly, and an axial loading cylinder 7; the sample holding assembly is provided with a useful In the sample installation cavity for clamping the rock sample 4, and the top of the sample clamping assembly is installed on the mounting frame 1 through the load sensor 2, and the bottom of the sample...

Embodiment 2

[0107] This embodiment proposes a long-duration and high-precision rheological test system for simulating complex deep ground conditions. The rheological test system is a uniaxial compression rheological test system. Such as Figure 5-Figure 7 As mentioned above, compared with the triaxial compression rheological test system disclosed in Example 1, the uniaxial compression rheological test system lacks lateral loading components that provide lateral loading and lateral stability.

[0108] The uniaxial compression rheological test system includes an interconnected sample installation assembly, a loading mechanism, and a hydraulic station module connected to the sample installation assembly and the loading mechanism for liquid supply;

[0109] The sample mounting assembly includes a mounting frame 1 and a load sensor 2 installed in the mounting frame 1 from top to bottom, a sample holding assembly, and an axial loading cylinder 7; the sample holding assembly is provided with a u...

Embodiment 3

[0123] This embodiment proposes a long-duration and high-precision rheological test system for simulating complex conditions in deep ground, and the rheological test system is a uniaxial tensile rheological test system. Such as Figure 8-Figure 10 As shown, compared with the triaxial compression rheological test system disclosed in Example 1, the described uniaxial tensile rheological test system lacks the lateral loading components that provide lateral loading and lateral stable load, while the sample installation components Instead of the force acting in the direction of compression, the force acting in the direction of tension is provided to the specimen.

[0124] The uniaxial tensile rheological test system includes an interconnected sample installation assembly, a loading mechanism, and a hydraulic station module connected to the sample installation assembly and the loading mechanism for liquid supply;

[0125] The sample mounting assembly includes a mounting frame 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com