Stepping servo actuator based on closed-loop control

A closed-loop control, step-by-step technology, applied in the control of mechanical energy, electrical components, electromechanical devices, etc., can solve problems such as unfavorable product installation and operation, changes in size and weight specifications, and large combined structure volume, and achieve energy control performance growth. , Acceleration and deceleration performance improvement, the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

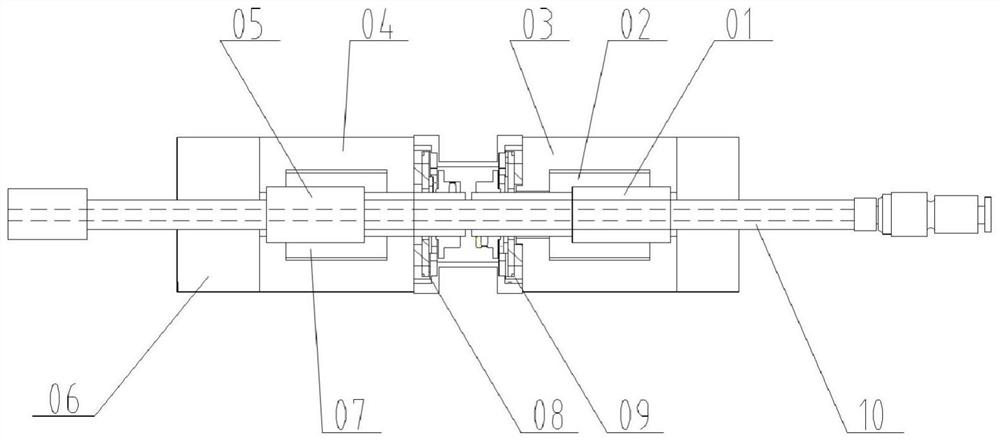

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams. It should be noted that the terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention are used to distinguish similar objects, and not necessarily Used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments described herein can be practiced in sequences other than those illustrated or described herein. Furthermore, the terms "comprising" or "having" and any variations thereof are intended to cover a non-exclusive inclusion, for example, a product or device comprising a series of constituent parts or units is not necessarily limited to those expressly listed constituent parts or units , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com