Ultrahigh-pressure metal fiber sintered felt and preparation method thereof

A metal fiber and sintered felt technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of strength influence, difference in bonding force, low monofilament strength, etc., to increase compressive capacity and reduce slurry waste. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of described a kind of ultra-high pressure metal fiber sintered felt is:

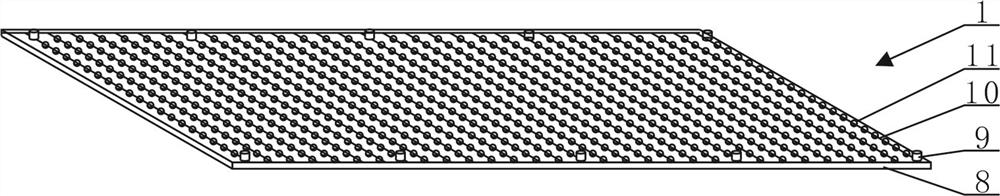

[0037] In the first step, the first mesh body 1 adopts stainless steel fiber mesh, and the metal fibers of the stainless steel fiber mesh of the first mesh body 1 are made into stainless steel fiber mesh by non-woven airflow forming equipment, and the discreteness of the stainless steel fiber mesh of the first mesh body 1 The coefficient is less than 3%, and the diameter of the metal fiber of the stainless steel metal mesh of the first mesh body 1 is 0.15 to 0.65 times of the filtration accuracy;

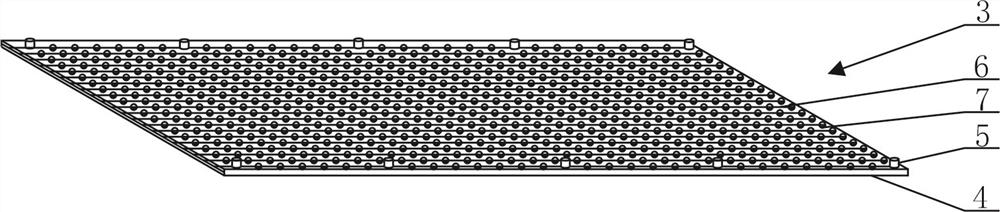

[0038] The metal fibers of the stainless steel fiber mesh of the third mesh body 3 are made of stainless steel fiber mesh by non-woven airflow forming equipment, and the dispersion coefficient of the stainless steel fiber mesh of the third mesh body 3 is less than 3%. The stainless steel metal mesh of the third mesh body 3 The diameter of the metal fiber is 1.1 to 1.6 times the d...

Embodiment 1~7

[0048] Examples 1-7, the present invention discloses an ultra-high pressure metal fiber sintered felt and its preparation method. The present invention arranges the second steel wire 10 and the second bayonet 9 on the second frame body 8, and the second steel wire 10 The second ball 11 is set, the first frame body 4 is set with the first steel wire 6 and the first detent 5, the first steel wire 6 and the first detent 5 are set on the first steel wire 6, and the first circle is set on the first steel wire 6. Ball 7, a third frame body 31 is provided between the first frame body 4 and the second frame body 8, a steel mesh 12 is arranged on the third frame body 31, and the second bayonet pin 9 is snapped into the first bayonet pin 5, so as to In order to achieve the purpose of anti-compression and orderly distribution.

[0049] In addition, the first ball 7 on the third mesh body 3 snaps into the mesh 13 of the steel mesh 12 on the second mesh body 2, and the second ball 11 on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com