Structure improvement method for cooling water jacket of motorized spindle

A cooling water jacket and structural improvement technology, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc. Convective heat transfer coefficient, the effect of enhancing heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below.

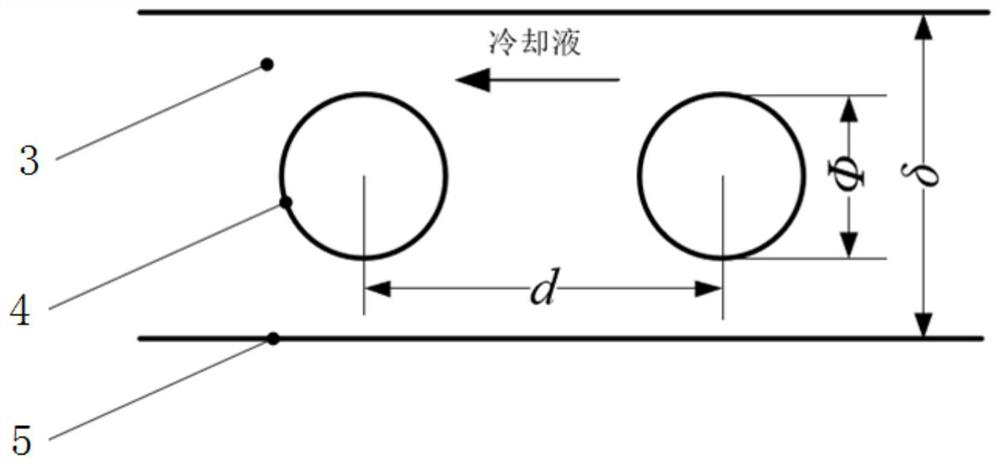

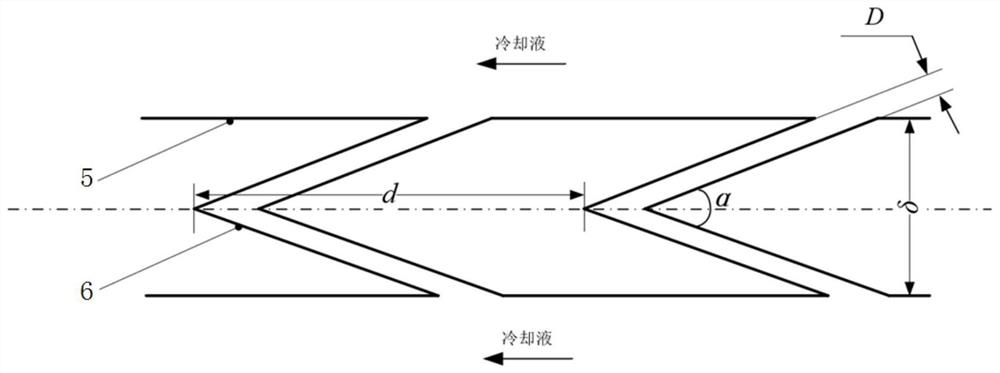

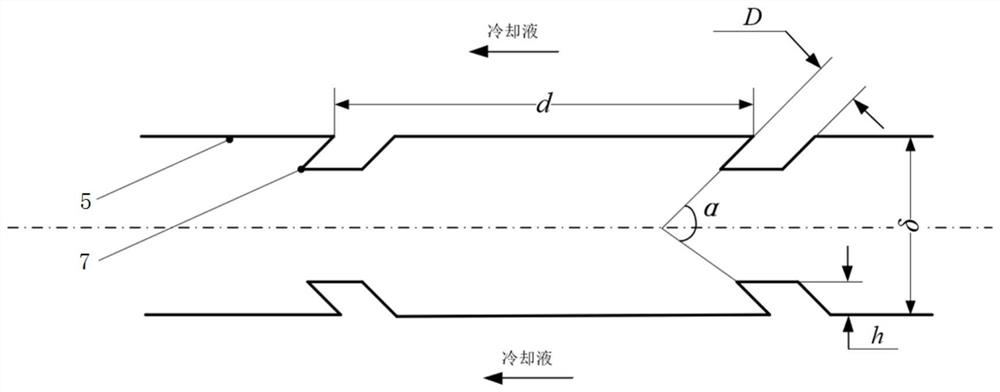

[0027] The invention relates to a method for improving the structure of the electric spindle cooling water jacket: changing the flow rate of the cooling liquid flowing through the cooling system by changing the layout of the inlet and outlet to a symmetrical orientation and carving grooves on the bottom and side walls of the spiral flow channel, destroying the The flow boundary layer changes its original stable flow state, thereby increasing its convective heat transfer coefficient, achieving the purpose of strengthening the heat transfer effect and reducing the temperature rise of the spindle.

[0028] The method includes the following steps:

[0029] 1) Simplify the cooling system of the electric spindle, that is, list the cooling water jacket and the shell separately for modeling. Since the improvement object is the structural form of the cooling water channel, some small features of the cooling water jacket and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| V-shaped angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com