Automobile sliding door guide rail and processing process thereof

A technology for guide rail processing and sliding doors, which is applied to doors, vehicle parts, door/window accessories, etc., and can solve the problems of reducing the service life of automobile sliding doors, bending and deformation of limit edges, and low structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

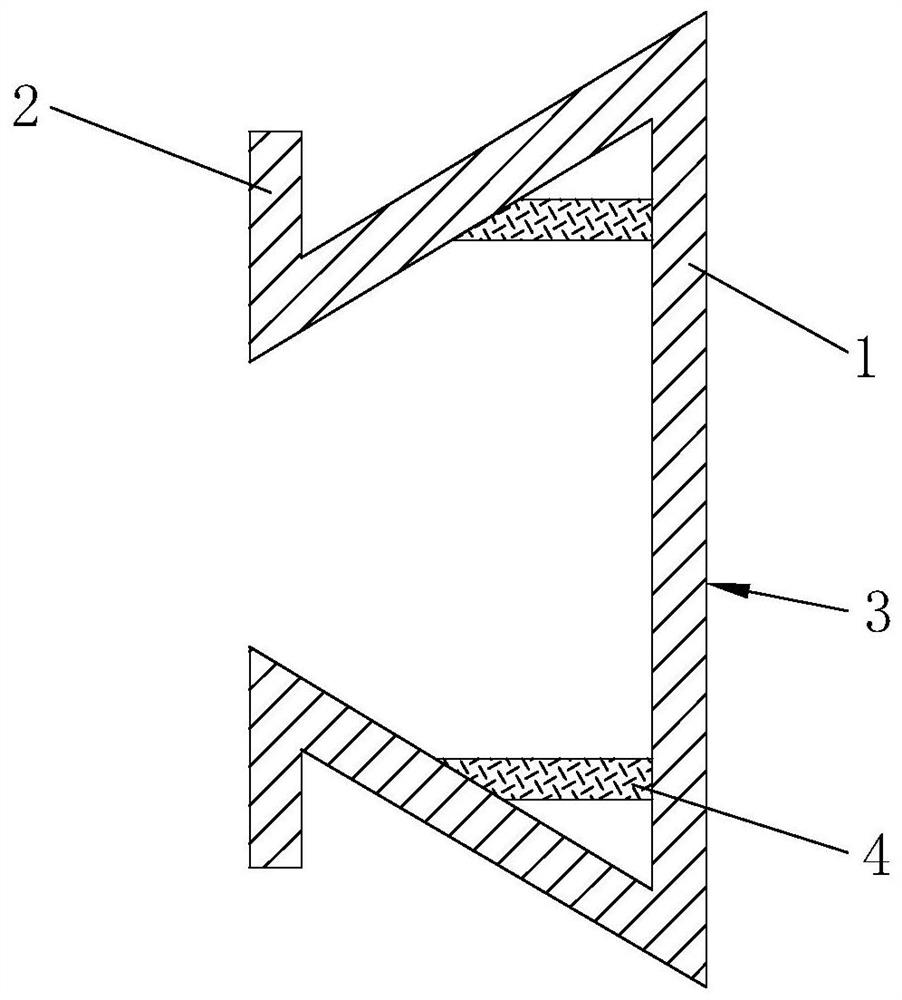

[0039] refer to figure 1 , is an automobile sliding door guide rail disclosed by the present invention, comprising a guide rail body 1, the guide rail body 1 is formed by bending a piece of steel strip plate, and the guide rail body 1 forms a tongue and groove slide rail structure along its length direction, the guide rail body 1 The two sides of 1 are integrally formed and fixedly connected with reinforcing plates 2, and the inner and outer surfaces of the guide rail body 1 are sprayed with high-strength paint 3.

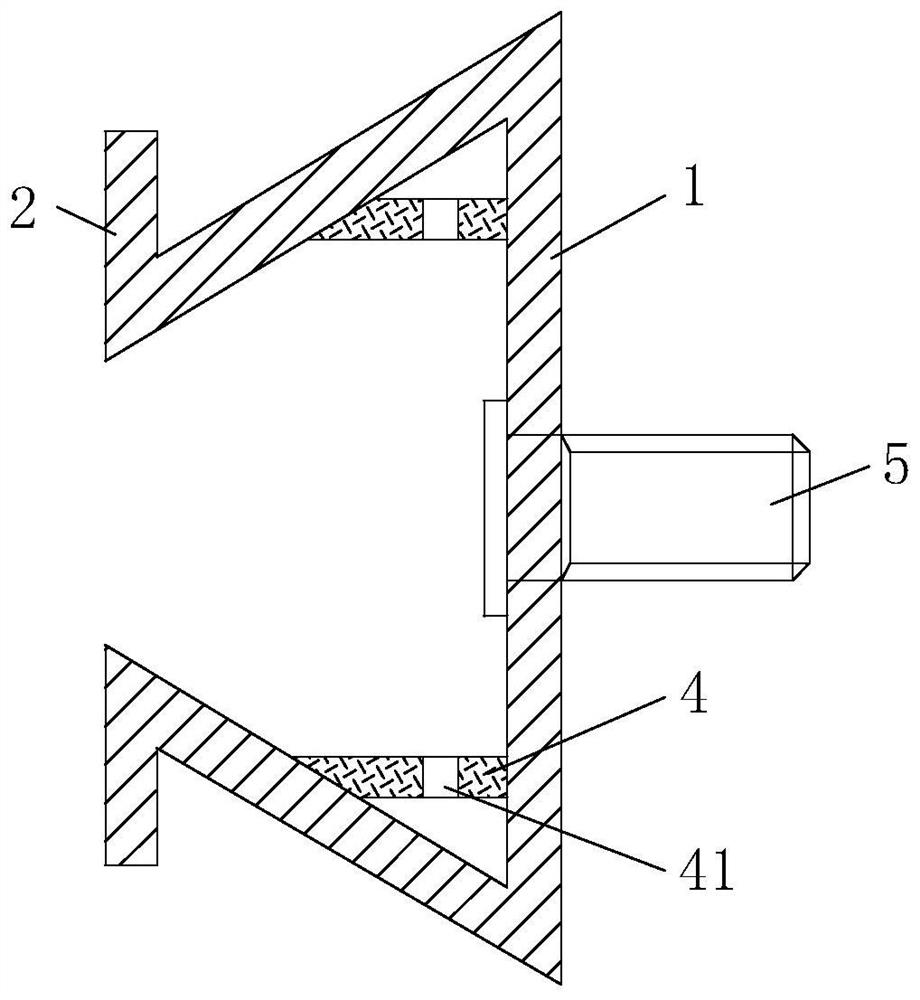

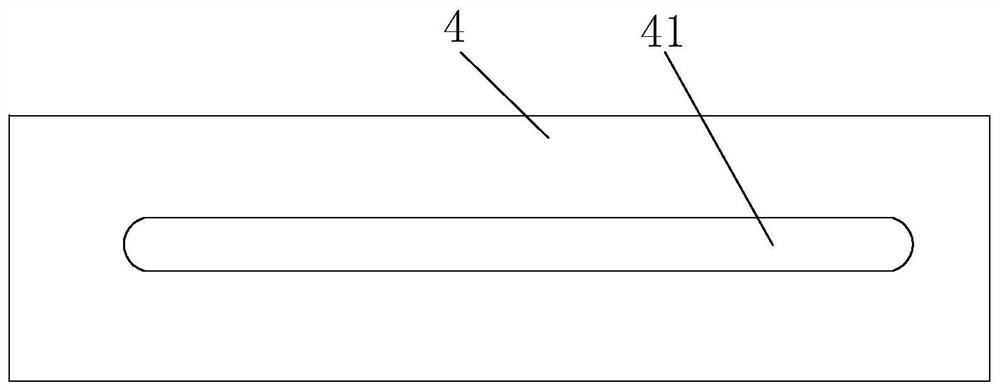

[0040] Among them, refer to figure 2 , the two sides inside the guide rail body 1 are respectively fixedly connected with the limiting plate 4, and the limiting plate 4 is provided with a waist-shaped groove 41 along its length direction (see image 3 ). The limiting plate 4 is arranged in the guide rail to provide a strong supporting force, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com