An automatic lubrication system

An automatic lubrication and grease pump technology, applied in the direction of engine lubrication, lubrication pump, lubrication parts, etc., can solve the problem that the lubricating grease cannot be adjusted quantitatively, does not have the self-protection function of lack of grease, etc., to save grease consumption and effectively lubricate , to meet the effect of lubrication requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

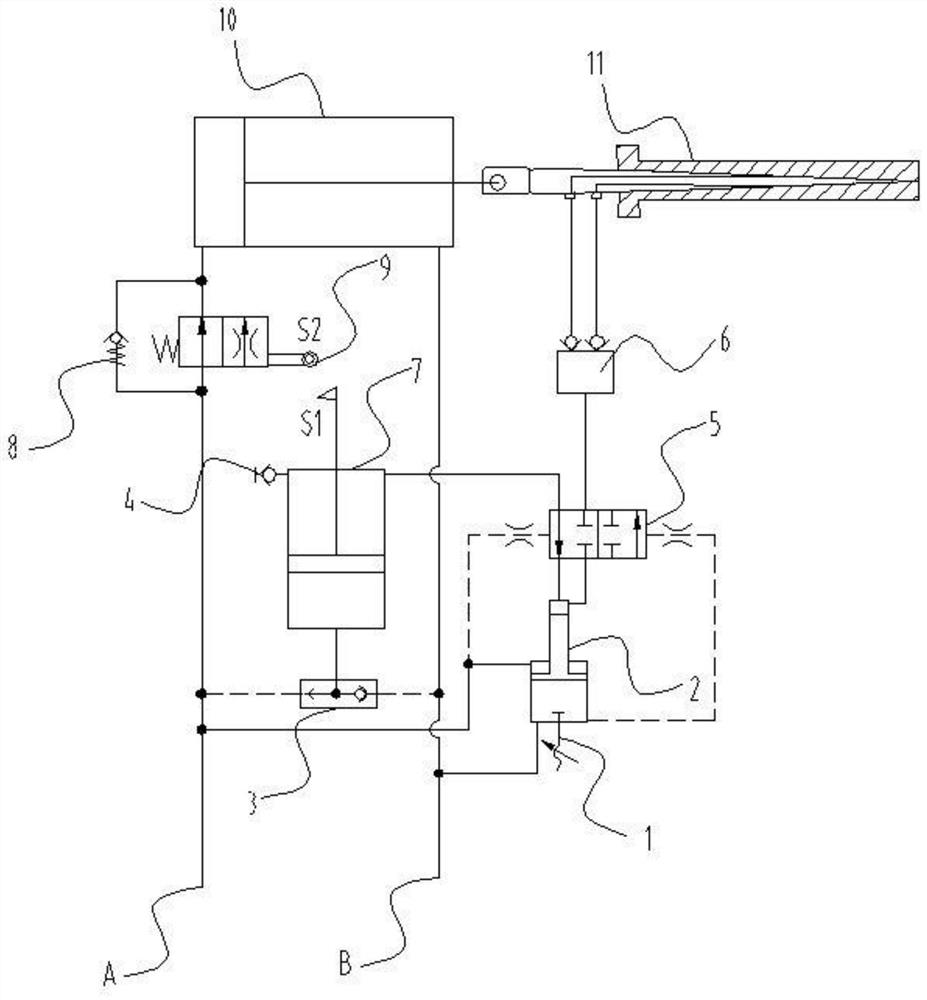

[0028] see figure 1 , an automatic lubricating system, this embodiment is applied to a splitting machine, and the "left", "right", "up", "down" and other directions described in this embodiment are all relative to the direction of the drawing.

[0029] An automatic lubrication system, comprising a liquid-driven grease pump 2, a hydraulic control reversing valve 5, a distributor 6, a grease tank 7, an oil cylinder 10, and a wedge block group 11; The split action reversing valve of the car, etc.) is connected to the working oil port; the oil circuit A and oil circuit B of the system are connected with the oil cylinder 10; the oil cylinder 10 is connected with the wedge block group 11, and is used to drive the wedge block group 11 to act; To control the extension and retraction of the oil cylinder 10, that is, the corresponding splitting and unloading actions, the oil circuit A and the oil circuit B are provided with a liquid-driven grease pump 2; the liquid-driven grease pump 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com