Preparation process of long-life diode

A preparation process and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult concentricity assurance, many pitting, and unclean cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1. A preparation process for a long-life diode, characterized in that:

[0062] Including the following steps:

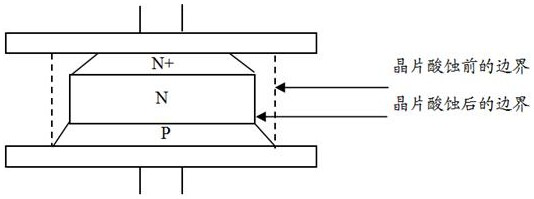

[0063] Step 1: Preparation of Diode Die

[0064] 1.1: Pre-cut in the thickness direction of the silicon wafer to form incompletely cut diode grains, and the cutting depth of the silicon wafer is 2 / of the total thickness of the silicon wafer.

[0065] 1.2: Put the pre-cut silicon wafer in the thickness direction N side down on the crystal cracking paper, with the cutting edge facing upward, and press lightly, so that the incompletely cut diode crystal grains are completely cracked to form a wafer.

[0066] Step 2: Rosin Isopropanol Solution Sprayed to Copper Lead Electrodes

[0067] In the rosin isopropanol solution, the mass ratio of rosin to isopropanol is 1:10;

[0068] Step 3: Filling

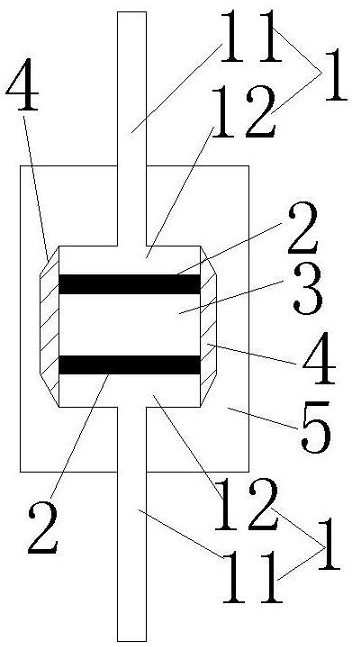

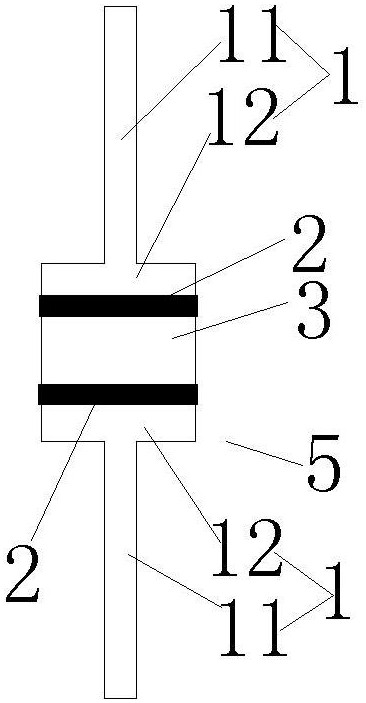

[0069] Put two copper lead electrodes 1, two soldering pieces 2, and chip 3 into the fixture; each copper lead electrode includes a table top 12 and a lead wi...

Embodiment 2

[0090] Example 2. A preparation process for a long-life diode, characterized in that:

[0091] Including the following steps:

[0092] Step 1: Preparation of Diode Die

[0093] 1.1: Pre-cut in the thickness direction of the silicon wafer to form incompletely cut diode grains, and the cutting depth of the silicon wafer is 3 / 4 of the total thickness of the silicon wafer;

[0094] 1.2: Put the pre-cut silicon wafer in the thickness direction N side down on the crystal cracking paper, with the cutting edge facing upward, and press lightly, so that the incompletely cut diode crystal grains are completely cracked to form a wafer.

[0095] Step 2: Rosin Isopropanol Solution Sprayed to Copper Lead Electrodes

[0096] In the rosin isopropanol solution, the mass ratio of rosin to isopropanol is 1:10-15;

[0097] Step 3: Filling

[0098] Put two copper lead electrodes 1, two soldering pieces 2, and chip 3 into the fixture; each copper lead electrode includes a table top 12 and a lea...

Embodiment 3

[0118] Example 3. A preparation process for a long-life diode, characterized in that:

[0119] Including the following steps:

[0120] Step 1: Preparation of Diode Die

[0121] 1.1: Pre-cut in the thickness direction of the silicon wafer to form incompletely cut diode grains, and the cutting depth of the silicon wafer is 2 / 3 of the total thickness of the silicon wafer;

[0122] 1.2: Put the pre-cut silicon wafer in the thickness direction N side down on the crystal cracking paper, with the cutting edge facing upward, and press lightly, so that the incompletely cut diode crystal grains are completely cracked to form a wafer.

[0123] Step 2: Rosin Isopropanol Solution Sprayed to Copper Lead Electrodes

[0124] In the rosin isopropanol solution, the mass ratio of rosin to isopropanol is 1:12;

[0125] Step 3: Filling

[0126]Put two copper lead electrodes 1, two soldering pieces 2, and chip 3 into the fixture; each copper lead electrode includes a table top 12 and a lead wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com