Taro ball frying equipment for food processing

A food processing and taro ball technology, which is applied in the field of food processing taro ball frying equipment, can solve the problems of low efficiency, accidental injury, etc., and achieve the effects of high safety, improved work efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

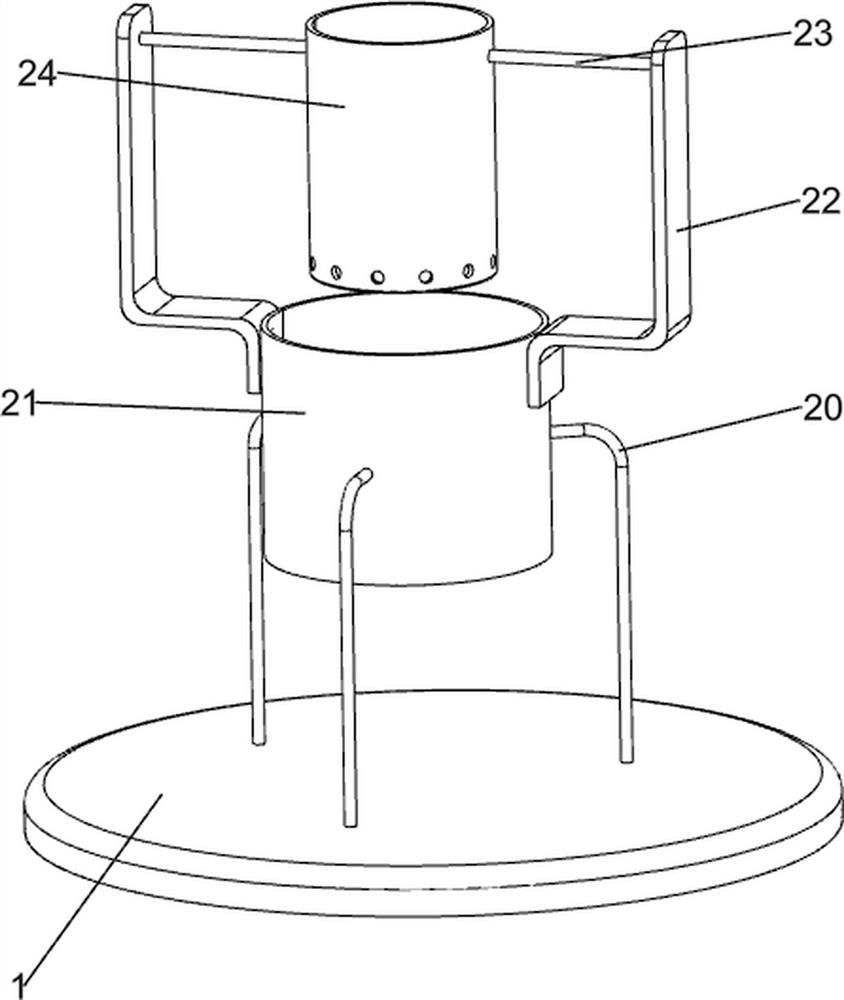

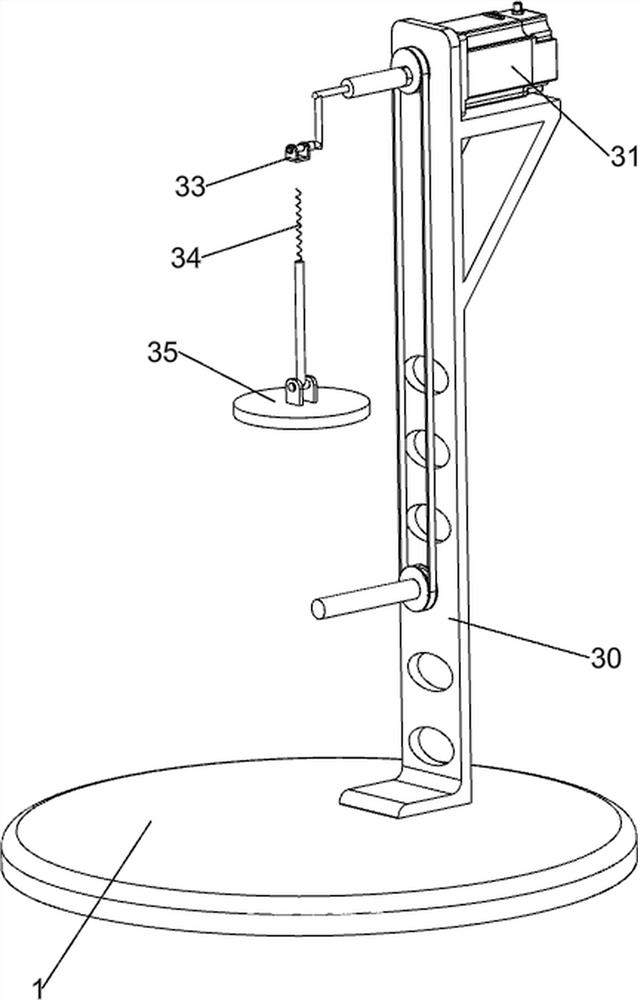

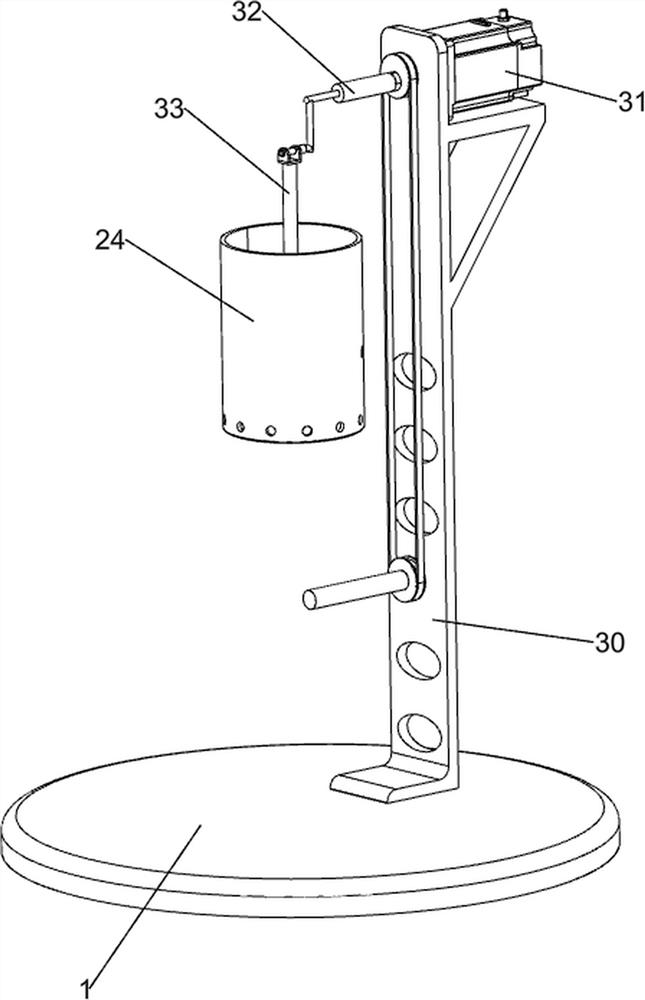

[0067] A kind of taro dumpling frying equipment for food processing, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it includes a bottom plate 1, a charging mechanism 2, an extruding mechanism 3 and a cutting mechanism 4. A charging mechanism 2 is arranged in the middle of the top of the bottom plate 1, and an extruding mechanism 3 is arranged on the rear side of the top of the bottom plate 1. On the top of the charging mechanism 2 A cutting mechanism 4 is provided.

[0068] The charging mechanism 2 includes a support rod 20, a frying bucket 21, a connecting plate 22, a connecting rod 23 and a charging box 24. Three support rods 20 are arranged in the middle of the top of the bottom plate 1, and a frying bucket is arranged between the tops of the three support rods 20. 21. Connecting plates 22 are provided on the left and right upper parts of the frying barrel 21, connecting rods 23 are provided on the inner upper part of the conne...

Embodiment 2

[0073] On the basis of Example 1, such as Figure 7 and Figure 8 As shown, it also includes a collection mechanism 5, the collection mechanism 5 includes an oil barrel 50, an oil guide pipe 51, a rotary switch 52, an oil storage tank 53, an oil delivery pipe 54 and a twist switch 55, and the left side of the bottom plate 1 is provided with an oil barrel 50, the top of the oil barrel 50 is provided with an oil guide pipe 51, the other end of the oil guide pipe 51 is connected with the frying barrel 21, the top of the oil guide pipe 51 is rotatably provided with a rotary switch 52, and the right side of the top of the bottom plate 1 is provided with an oil storage tank 53, the oil storage tank 53 tops are provided with oil delivery pipe 54, and oil delivery pipe 54 other ends are connected with frying bucket 21, and oil delivery pipe 54 top rotation type is provided with twist switch 55.

[0074] After people fry taro ball dumpling several times in frying barrel 21, turn switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com