Cooking equipment

A technology for cooking equipment and cooking cavity, applied in the field of kitchen utensils, can solve the problems of uneven heating of the cooking cavity 110 ′, oil stains, food residues left, affecting the cooking effect of food, etc., and achieves improved user experience, high cleanliness, improved The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

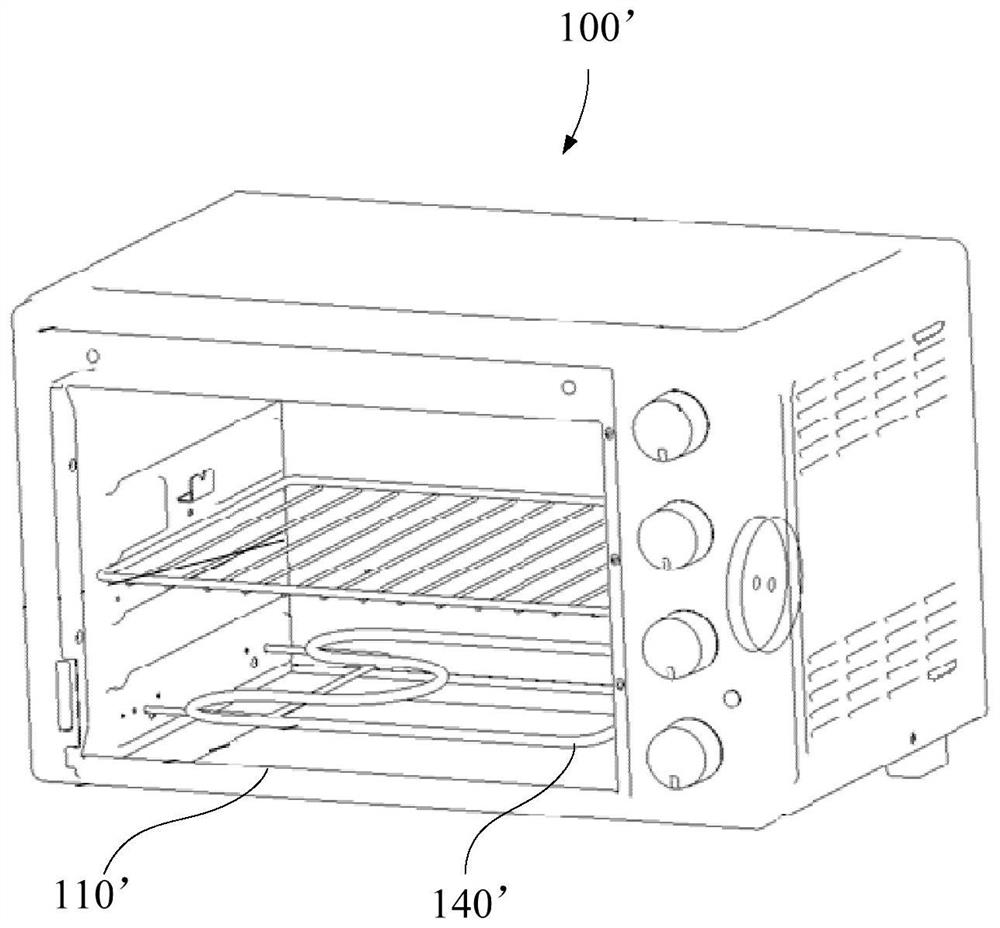

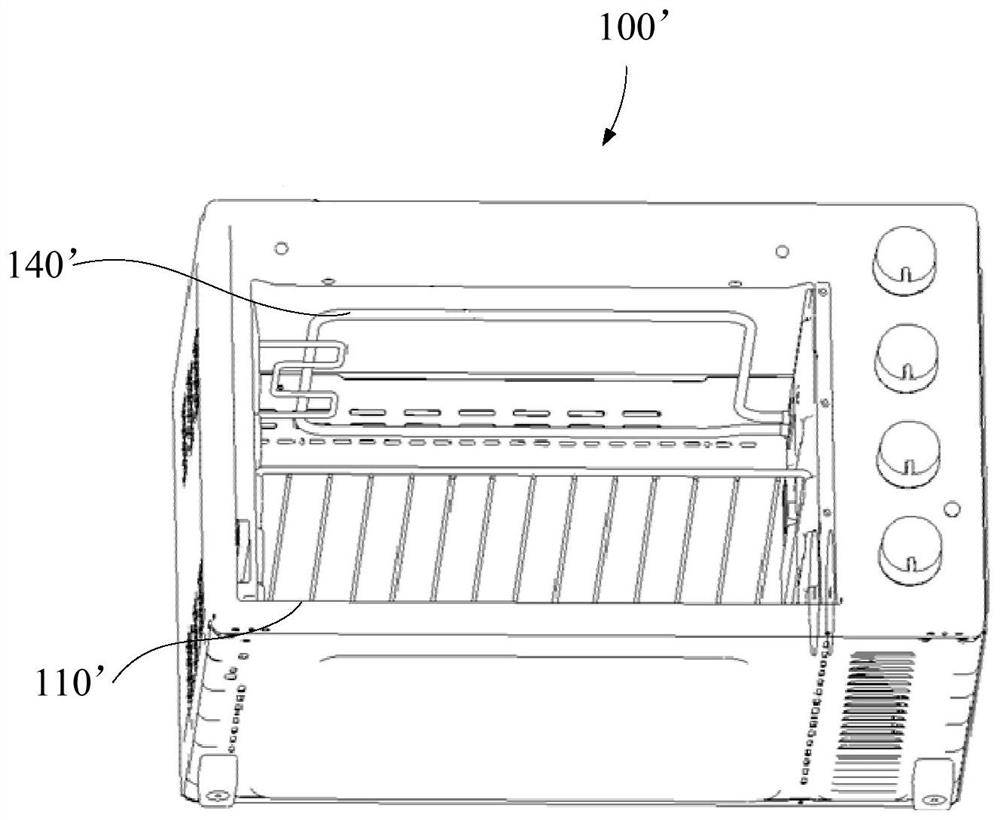

[0063] Such as Figure 3 to Figure 22 As shown, according to the first aspect of the present invention, a cooking device 100 is provided, including a cooking cavity 110, a cover plate 120 and a heat source 140, wherein the cover plate 120 is arranged on the inside or outside of the cooking cavity 110, and An accommodating cavity 130 is formed between the cover plate 120 and the cooking cavity 110 ; the heat source 140 is disposed in the accommodating cavity 130 .

[0064] Specifically, such as image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 As shown, the cover plate 120 of the cooking device 100 is arranged on the inside or outside of the cooking cavity 110, and an accommodating cavity 130 is formed between the cover plate 120 and the cooking cavity 110, and the heat source 140 is arranged in the accommodating cavity 130, which can avoid heat source 140 is directly arranged in the cooking cavity 110, during the cooking process, there will be oil stains and food 2...

Embodiment 2

[0068] Such as Figure 3 to Figure 22 As shown, in one embodiment of the present invention, the cooking device 100 is equipped with a cooking cavity 110, a cover plate 120, a heat source 140 and a partition 150, wherein the partition 150 is arranged between the heat source 140 and the cooking cavity 110, and Connect with the cover plate 120.

[0069] In this example, if Figure 4 , Figure 5 , Image 6 , Figure 10 , Figure 11 , Figure 13 , Figure 14 , Figure 15 As shown, a partition 150 is set between the heat source 140 and the cooking cavity 110, and the partition 150 is opposite to a part of the heat source 140. Since the heating value of the heat source 140 itself is not uniform, it is connected to the cover plate 120 through the partition 150 and connected to the part of the heat source 140. Located opposite to the heat source 140, the partition 150 is used to separate the area of the heat source 140 with a high calorific value from the cooking cavity 110, ...

Embodiment 3

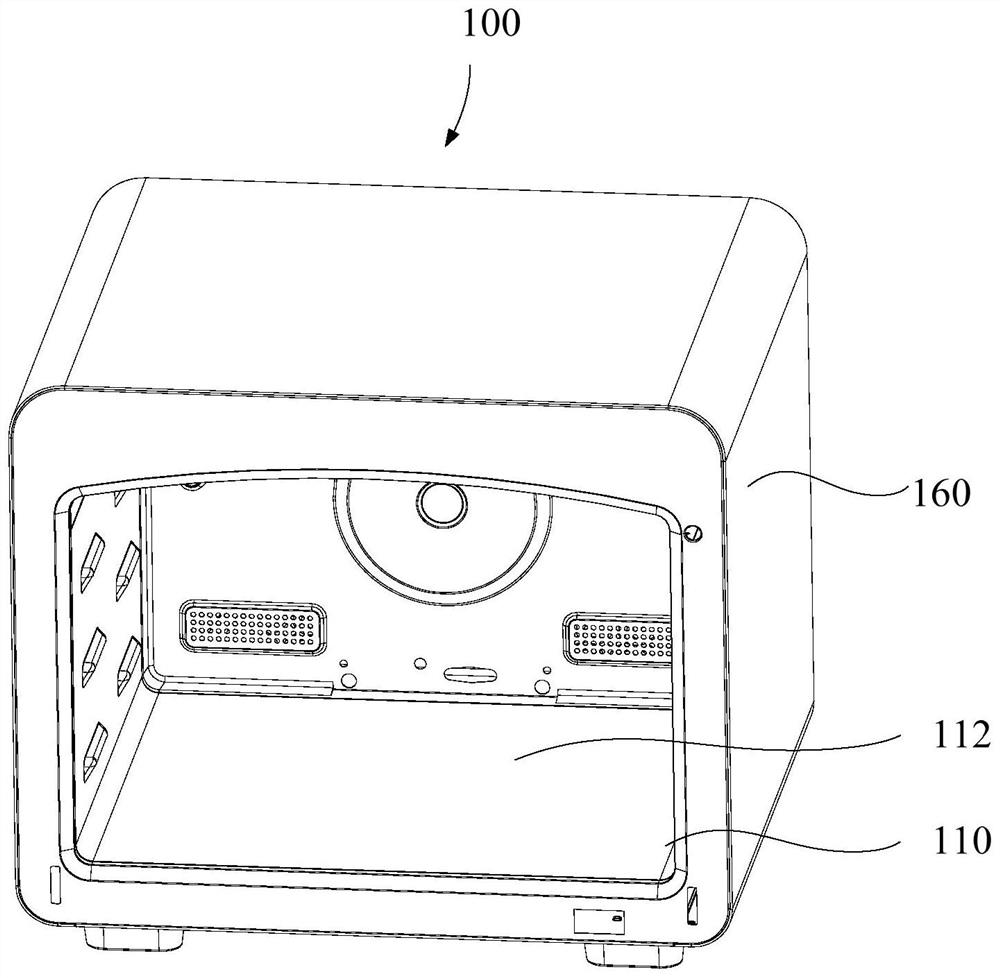

[0073] Such as Figure 3 to Figure 22 As shown, in one embodiment of the present invention, the cooking device 100 includes a cooking cavity 110, a cover plate 120, a heat source 140 and a partition 150, wherein the cooking cavity 110 is configured as a cooking cavity 112 having an opening, and the cooking cavity 110 includes a plurality of cavity walls 114 , and a cover plate 120 is disposed on at least one of the plurality of cavity walls 114 and is located outside the cooking cavity 112 .

[0074] In this example, if Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 16 , Figure 17 , Figure 18 , Figure 19 As shown, the cooking cavity 110 is configured as a cooking cavity 112 with an opening through which the food 200 to be cooked is placed in or removed from the cooking cavity 110, the cooking cavity 110 includes a plurality of cavity walls 114, The cover plate 120 is arranged on at least one of the plurality of cavity walls 114, so that the accommodating cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com