Artificial joint with stable structure lubricating layer and preparation method of artificial joint

A technology for stabilizing structure and artificial joints, applied in coatings, pharmaceutical formulations, medical science, etc., can solve the problems of unstable coating structure, easy swelling of coatings, etc., and achieve good structural integrity and lubricating performance effectiveness, The effect of stable connection bonding and good service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

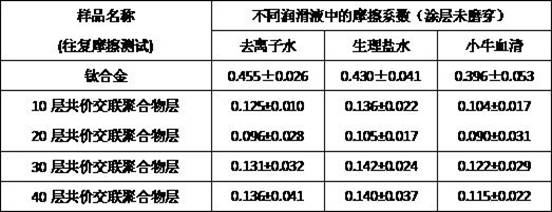

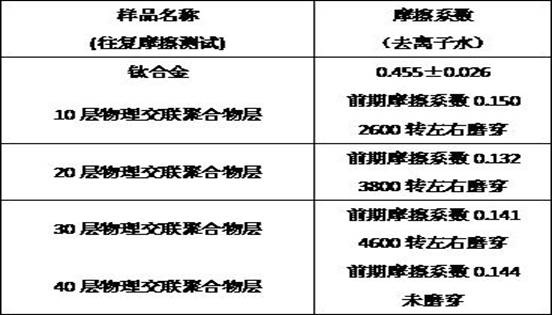

Embodiment 1

[0052] Oxygen plasma treatment was performed on the titanium alloy for 5 minutes to obtain a hydroxylated substrate; the hydroxylated substrate was immersed in a polyacrylamine hydrochloride polycation electrolyte aqueous solution with a concentration of 0.05 mg / mL for 30 minutes, and then cleaned with deionized water; Immerse in a polyacrylic acid polyanion electrolyte aqueous solution with a concentration of 0.05 mg / mL for 30 minutes, take it out, wash and dry it; immerse it in the two polyelectrolyte solutions for 30 times to form 30 polycation electrolyte layers and 30 polyanion electrolyte layers alternately assembled The electrolyte layer; finally, the polyelectrolyte layer was immersed in a 1% glutaraldehyde solution for 10 min. Made 1# titanium alloy artificial joint with stable structural lubricating layer.

Embodiment 2

[0054] The titanium alloy was irradiated with ultraviolet light for 15 minutes to obtain a hydroxylated substrate; the hydroxylated substrate was immersed in a polyethyleneimine polycation electrolyte solution with a concentration of 5 mg / mL for 5 minutes, and it was taken out and cleaned with deionized water; Then immerse in the polyacrylic acid polyanion electrolyte aqueous solution with a concentration of 5 mg / mL for 5 minutes, take it out, wash and dry it; immerse it in the two polyelectrolyte solutions for 10 times to form 10 layers of polycation electrolyte layer and 10 layers of polyanion electrolyte layer alternately Assembled electrolyte layer; finally, the polyelectrolyte layer was immersed in a 0.1% glutaraldehyde solution for 30 min. Made 2# titanium alloy artificial joint with stable structural lubricating layer.

Embodiment 3

[0056] The titanium alloy was treated with NaOH alkali solution, the concentration was 3 mol / L, and the water bath was kept at 60°C for 8 hours to obtain the hydroxylated substrate; the hydroxylated substrate was immersed in the polyallylamine hydrochloride polycation electrolyte with a concentration of 1 mg / mL 10 min in the aqueous solution, take it out and wash it with deionized water; then immerse it in the polymethacrylic acid polyanion electrolyte aqueous solution with a concentration of 1 mg / mL for 10 min, take it out, wash it and dry it; An electrolyte layer assembled alternately with 20 layers of polycation electrolyte layers and 20 layers of polyanion electrolyte layers; finally, the polyelectrolyte layer was immersed in a 2% glutaraldehyde solution for 20 min. Made 3# titanium alloy artificial joint with stable structural lubricating layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com