Stirring method of rotary deflection high-speed axial flow stirring robot group

A technology of a stirring machine and a stirring method, which is applied to a mixer with a rotating stirring device, a chemical instrument and method, a mixing method, etc., can solve the problems of uneven mixing and poor mixing effect of materials, and achieves a high level of material mixing. The effect of uniformity, sufficient material stirring and mixing, and high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

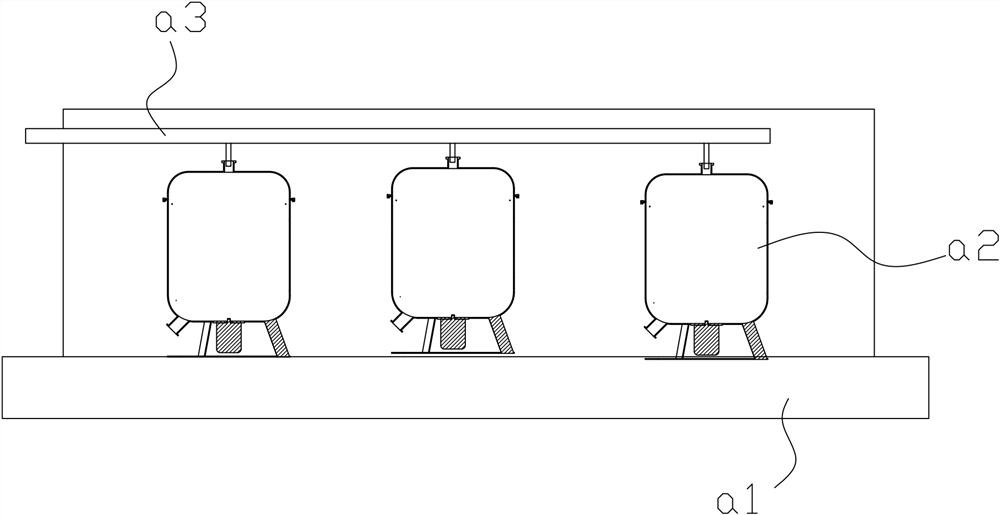

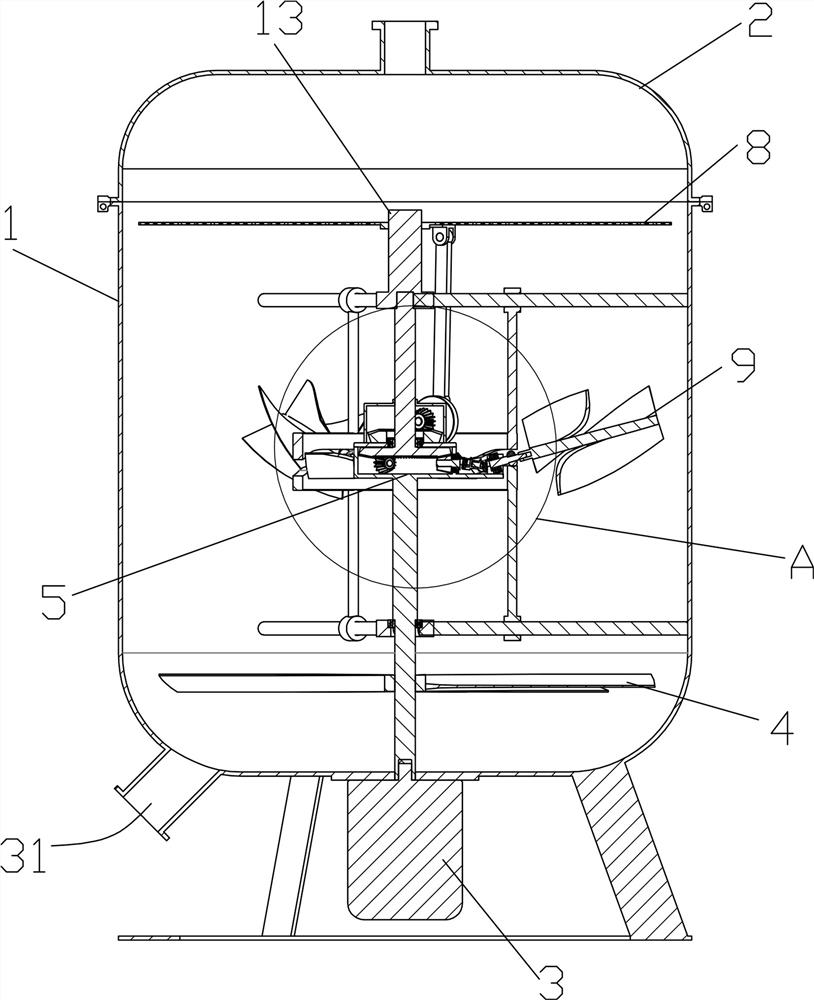

[0028] Such as Figure 1 to Figure 6 As shown, the stirring method of a rotary yaw high-speed axial-flow stirring robot group described in this embodiment includes a base platform a1, the base platform includes a base and a back wall; the base platform is provided with multiple side-by-side arrangements The stirring robot tank; also includes a transmission material pipe a3, and the transmission material pipe is provided with a plurality of feeding pipes respectively corresponding to each stirring robot tank a2.

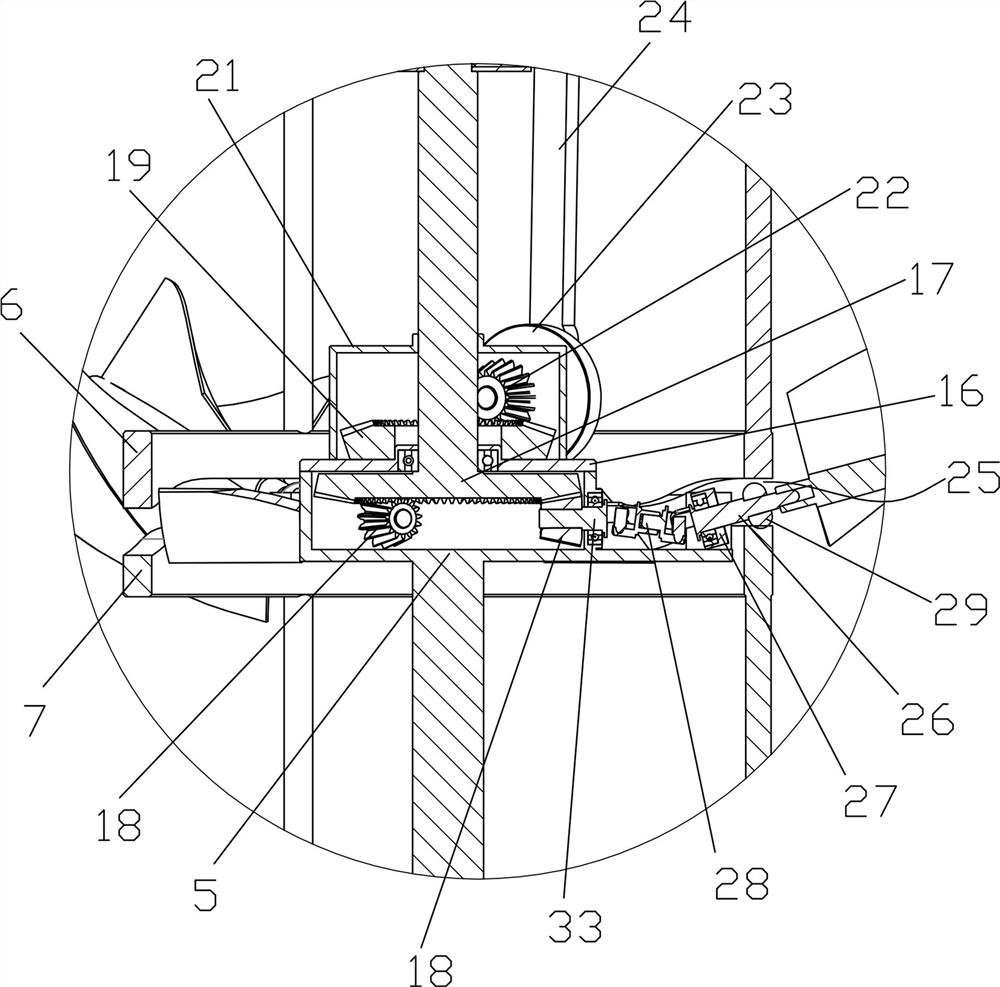

[0029] The stirring robot tank includes a stirring tank body 1, a stirring cover 2 detachably connected to the top of the stirring tank body 1, a driving motor 3, an axial flow stirring paddle 4, a rotating paddle seat 5, a ring-shaped upper end cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com