Paint spraying processing assembly line

An assembly line and paint technology, applied in coatings, spray booths, spraying devices, etc., can solve problems such as unfavorable use of workpieces, affecting paint spraying work, and inability to remove sundries and dust on the surface of workpieces, achieving strong adaptability and convenience The effect of centralized collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

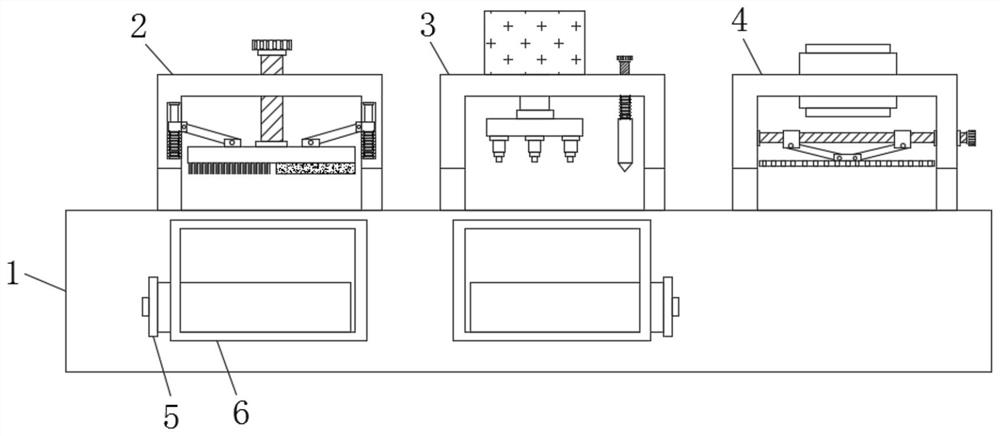

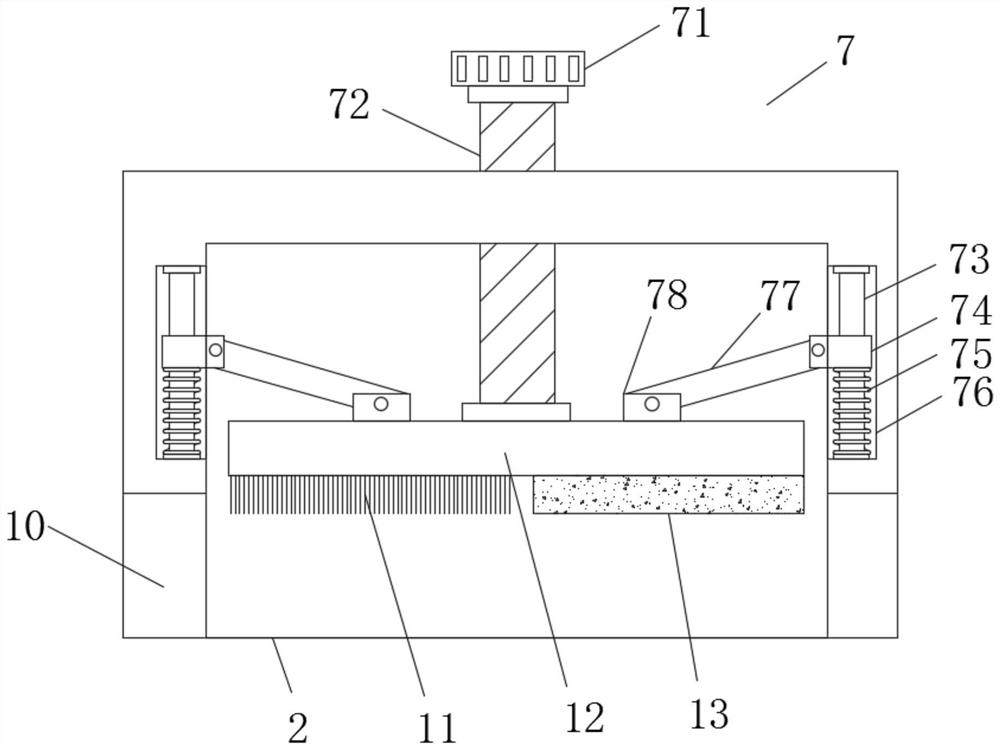

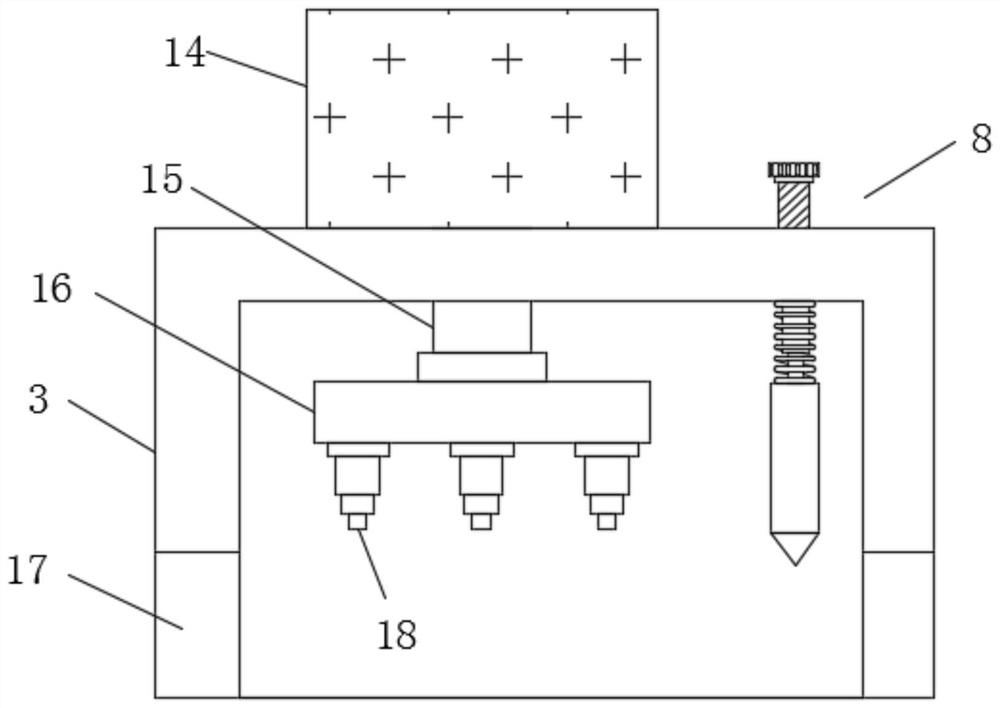

[0029] like Figure 1-7 As shown, the present invention provides a paint spraying processing line, including a side plate 1, two side plates 1 are provided, the upper ends of the two side plates 1 are provided with installation grooves 21, and conveyor belts are provided in the two installation grooves 21 22. The upper ends of the two side plates 1 are fixedly connected with the first shell 2, the first port 10 is provided on both sides of the first shell 2, the first shell 2 is provided with a mounting plate 12, and the mounting plate 12 is adjusted by adjusting The mechanism 7 is connected with the first housing 2, the bottom end of the mounting plate 12 is fixedly connected with a brush 11 and a wiping cloth 13 respectively, and a second housing 3 is provided on one side of the first housing 2, and the second housing 3 is fixedly connected to the The upper ends of the two side plates 1 and the second ports 17 are arranged on both sides of the second housing 3, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com