Automatic production system

A production system and vibrating plate technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high production costs and low quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The present invention will be further described below in conjunction with specific embodiments:

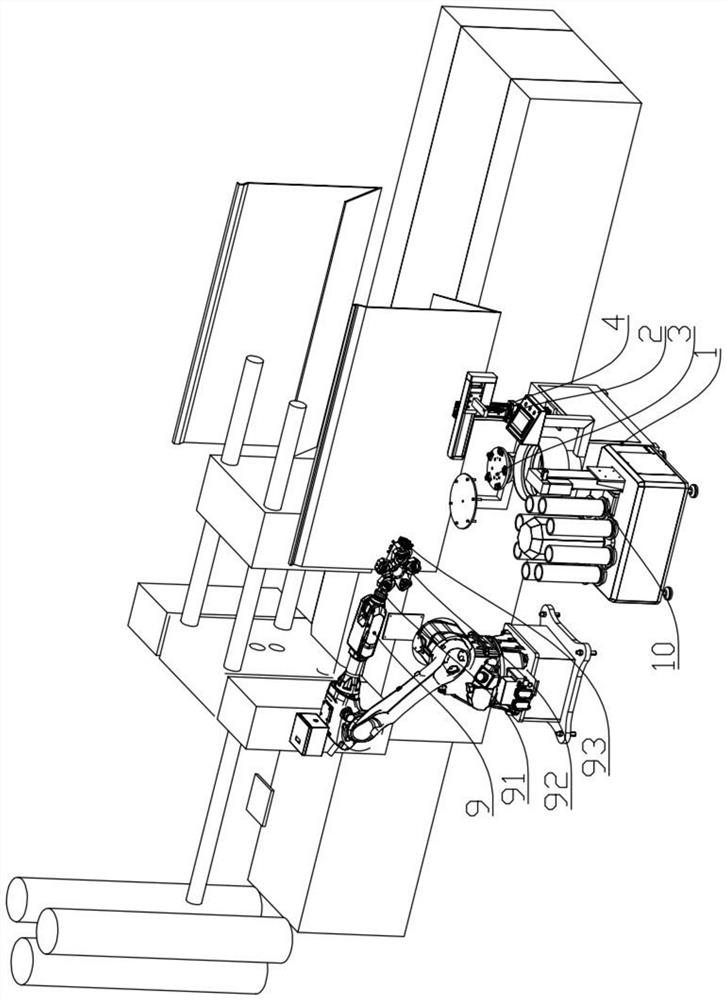

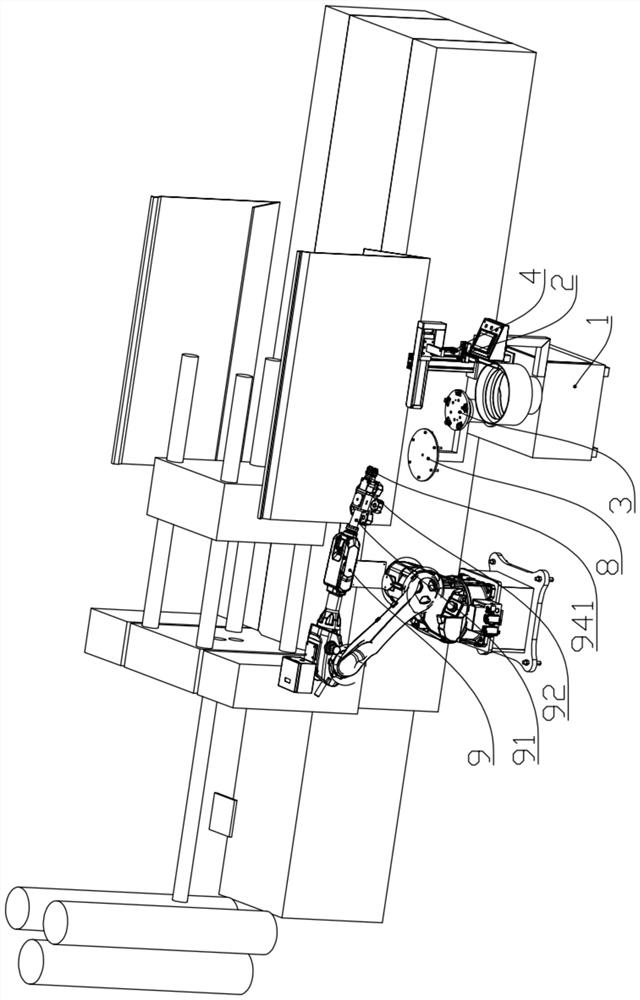

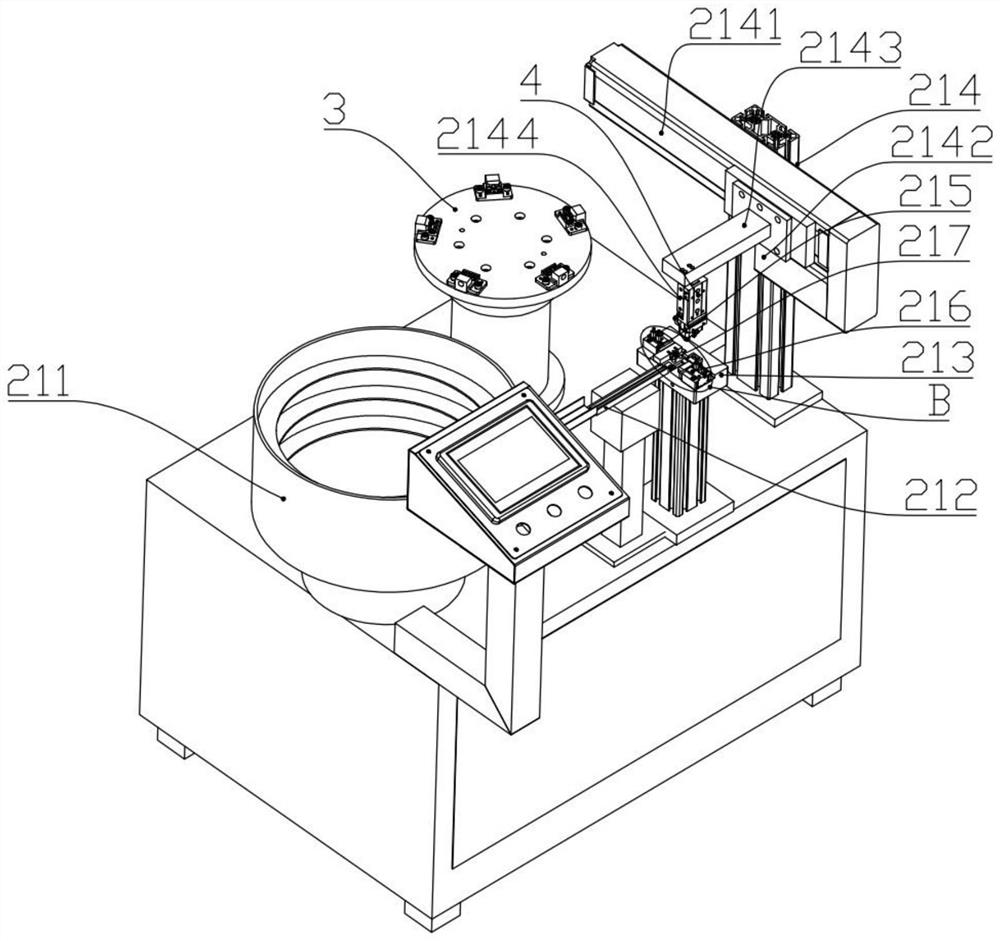

[0052]Automated production system, referenceFigure 1-14 The frame 1, the frame 1 is provided with a grab mechanism 2 and the aspirated coil apparatus 3, and the frame 1 is provided with a robotic mechanism 9 including a vibrating plate 211, and a vibrating plate. 211 The vibrating disk interface 212 connected at the exit is connected to the positioning geese 213 connected to the vibrating disk interface 212 and the grip device 214 located by the positioning of the smectite 213, and the web is positioned relative to the web. 215 and The pusher 216 is provided with at least one positioning pin 217 on the positioning of the gewed weapper 213, and the positioning pin 217 is located between the tapered device 215 and the pusher 216. In this embodiment, two jaws 217 are provided on the positioning weapper 213, and the three positioning pins 217 are located on the same side of the two jaws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com