A method for in-situ synthesis of molybdenum-silicon-boron alloy coating by laser cladding

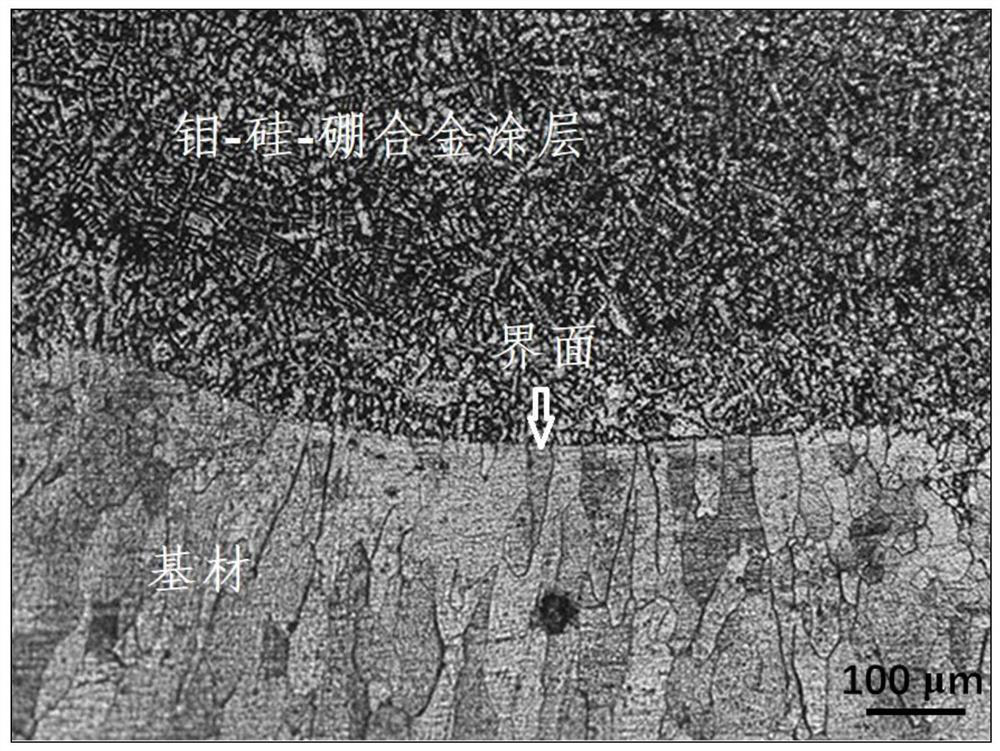

A laser cladding and in-situ synthesis technology, which is applied in the coating process and coating of metal materials, can solve the problems of boron volatile loss, complicated preparation process, high melting point, etc., and achieve no crack defects, good bonding, and high composition Tissue even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1. Use 200-mesh sandpaper to mechanically grind, degreasing and rust the molybdenum plate to obtain a bright and flat surface as a base material;

[0029] Step 2: Mechanically mixing spherical molybdenum powder, silicon powder and boron carbide powder to obtain mixed powder; the mass content of silicon powder in the mixed powder is 4.5%, the mass content of boron carbide powder is 1.5%, and the balance is spherical Molybdenum powder, and the particle size of spherical molybdenum powder, silicon powder and boron carbide powder are all 200 mesh;

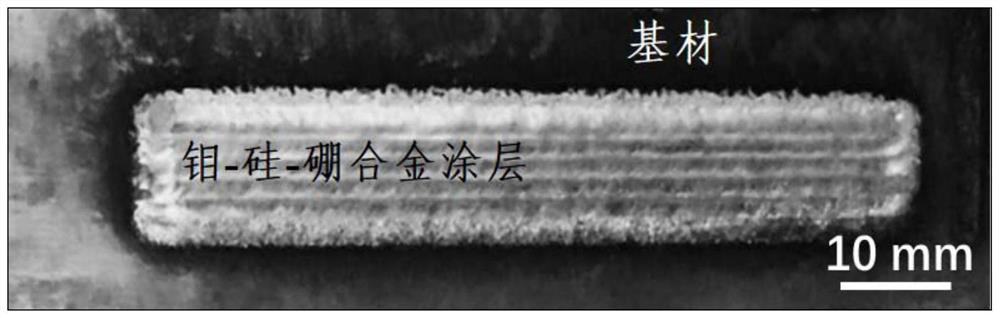

[0030] Step 3: Laser cladding the mixed powder obtained in Step 2 on the substrate selected in Step 1, and in-situ synthesis to obtain a molybdenum-silicon-boron alloy coating with a thickness of 0.2 mm; the laser cladding adopts In the method of coaxial powder feeding, the laser power is 1600W, the diameter of the laser beam spot is 2.5mm, the laser scanning speed is 7m...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] Step 1. Use 200-mesh sandpaper to mechanically grind, degreasing and rust the molybdenum plate to obtain a bright and flat surface as a base material;

[0036] Step 2: Mechanically mixing spherical molybdenum powder with silicon powder and boron carbide powder to obtain mixed powder; the mass content of silicon powder in the mixed powder is 6%, the mass content of boron carbide powder is 3%, and the remainder is spherical Molybdenum powder, and the particle size of spherical molybdenum powder, silicon powder and boron carbide powder are all 200 mesh;

[0037] Step 3: Laser cladding the mixed powder obtained in Step 2 on the substrate selected in Step 1, and in-situ synthesis to obtain a molybdenum-silicon-boron alloy coating with a thickness of 0.4 mm; the laser cladding adopts In the method of coaxial powder feeding, the laser power is 1800W, the diameter of the laser beam spot is 2.0mm, the laser scanning speed i...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1. Use 200-mesh sandpaper to mechanically grind, degreasing and rust the molybdenum plate to obtain a bright and flat surface as a base material;

[0041] Step 2: Mechanically mixing spherical molybdenum powder with silicon powder and boron carbide powder to obtain mixed powder; the mass content of silicon powder in the mixed powder is 3%, the mass content of boron carbide powder is 1%, and the remainder is spherical Molybdenum powder, and the particle size of spherical molybdenum powder, silicon powder and boron carbide powder are all 200 mesh;

[0042] Step 3: Laser cladding the mixed powder obtained in Step 2 on the substrate selected in Step 1, and in-situ synthesis to obtain a molybdenum-silicon-boron alloy coating with a thickness of 0.5 mm; the laser cladding adopts In the method of coaxial powder feeding, the laser power is 1900W, the diameter of the laser beam spot is 1.5mm, the laser scanning speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com