A jigger and a jigging process using the jigger

The technology of a jigger and a pressing mechanism is applied in the field of jigger and jigger, which can solve the problems of reducing the dyeing effect of fabrics, difficult to control the tension force, and large error of the tension force, so as to improve the dyeing effect. , the effect of reducing errors and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

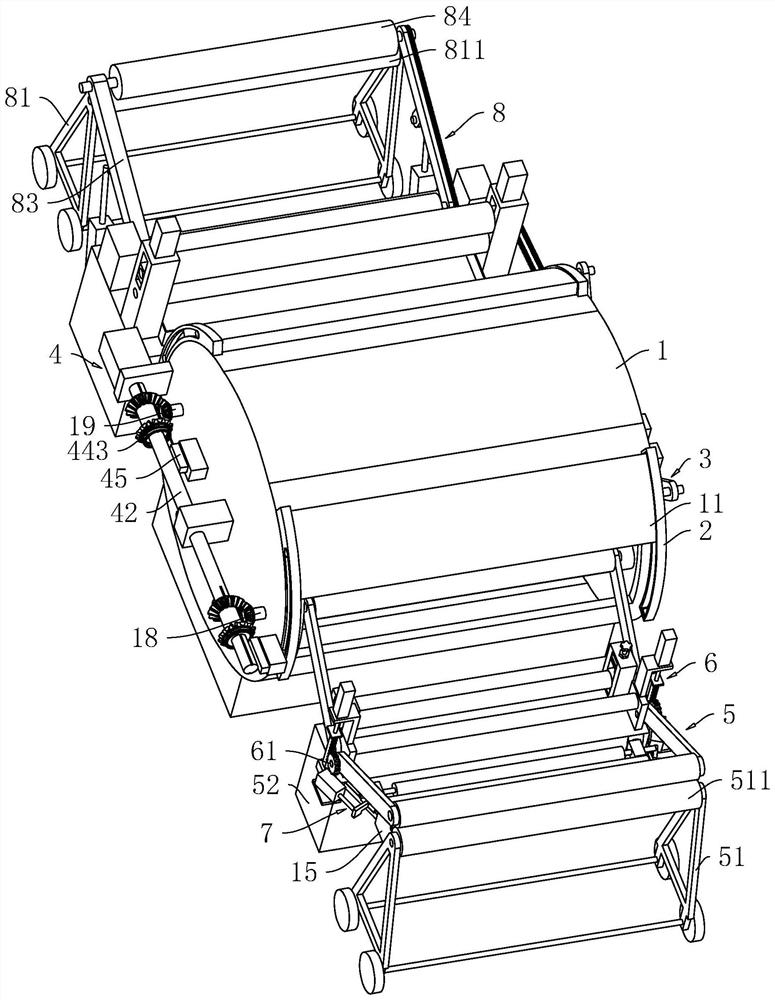

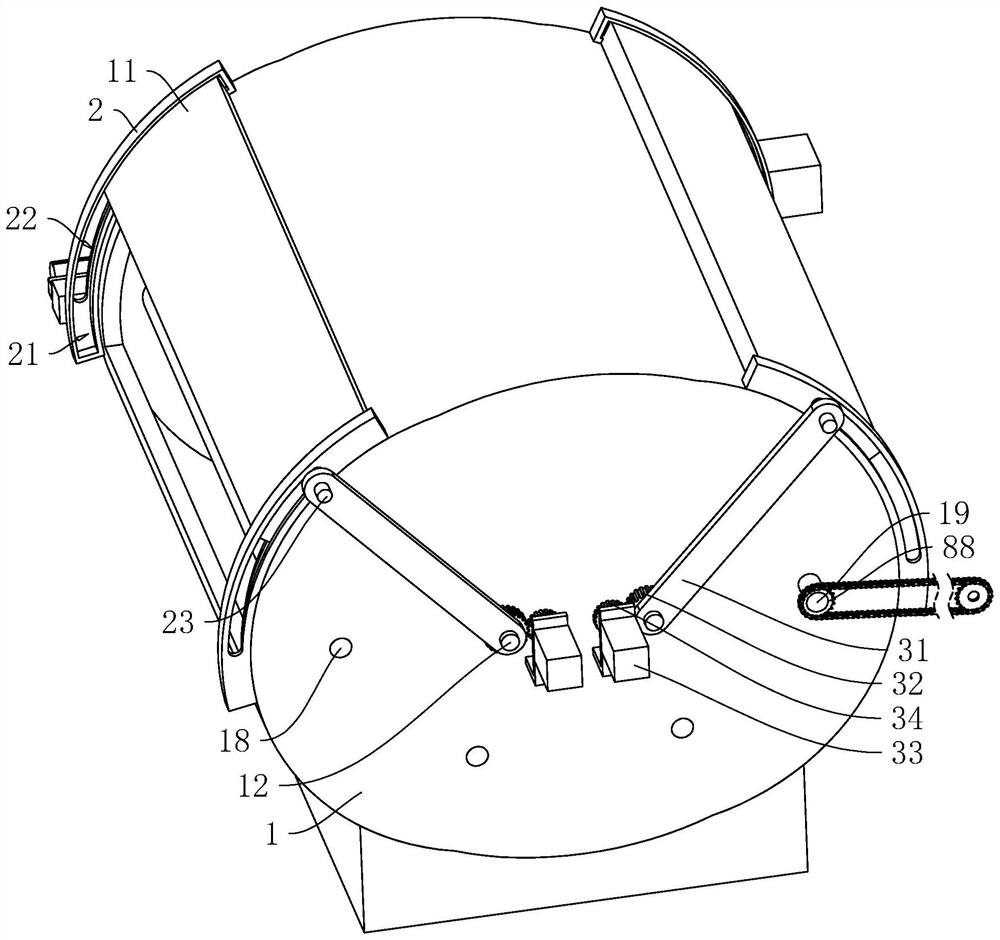

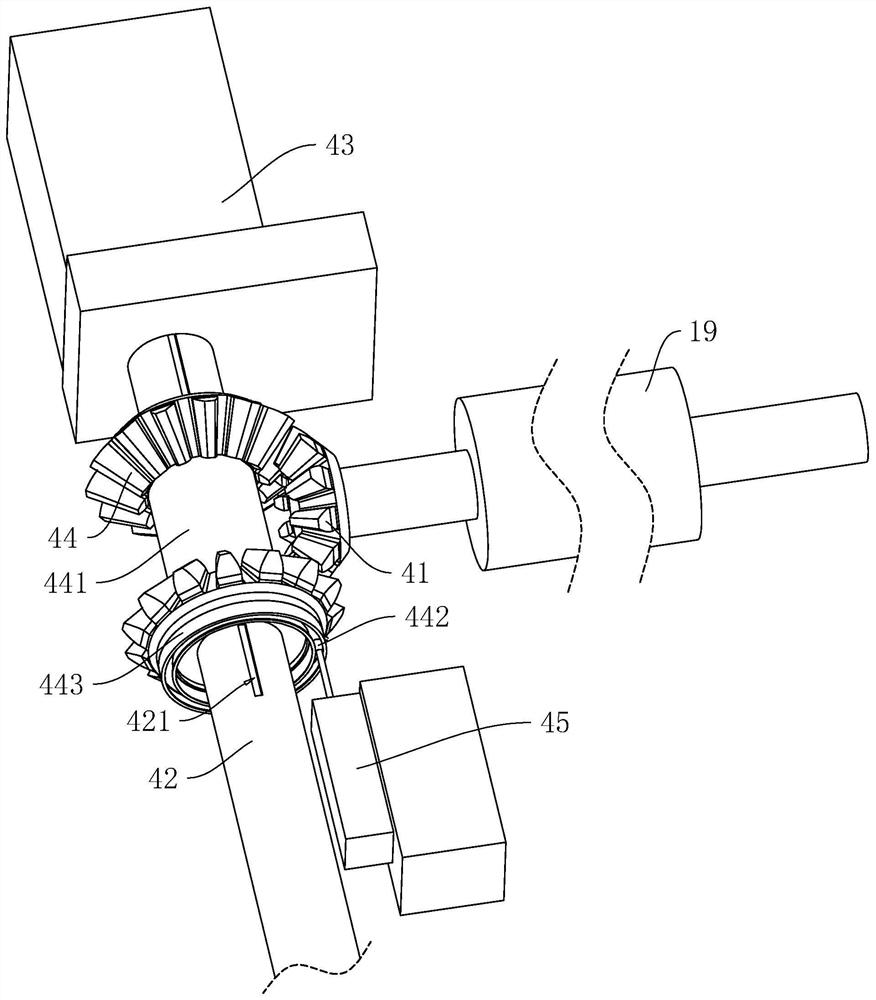

[0051] The present application will be further described in detail below with reference to the accompanying drawings for 1-7.

[0052] The embodiments of the present application disclose a jigger.

[0053] In this embodiment, the model of the force detector 544 is WZN, and the model of the infrared detector 75 is HF-HJ03.

[0054] refer to figure 1 and figure 2 , the jigger includes a cylindrical cylinder 1, the cylinder 1 is equipped with dye liquor, and the inner side wall of the cylinder 1 is rotated and installed with a cloth feeding roller 18 and a cloth discharging roller 19 that are parallel to each other, and the cloth feeding roller 18 and the cloth The rollers 19 are located on the same horizontal plane, while the cloth feeding rollers 18 and the cloth discharging rollers 19 are located above the liquid level of the dye liquor, and a plurality of cloth guide rollers are rotatably installed on the inner wall of the cylinder 1 below the liquid level.

[0055] refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com