Light wallboard easy to fabricate and manufacturing method thereof

A light-weight wallboard and wallboard technology, applied to walls, manufacturing tools, building components, etc., can solve the problems of cumbersome production, large amount of slotting, and heavy wallboard weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

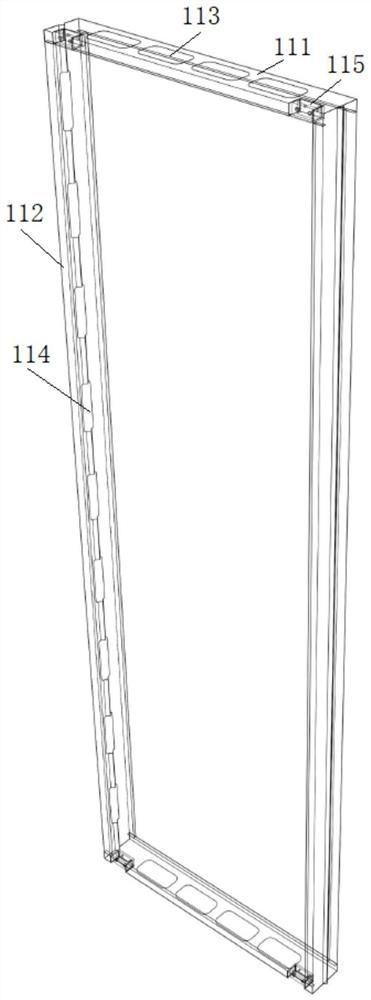

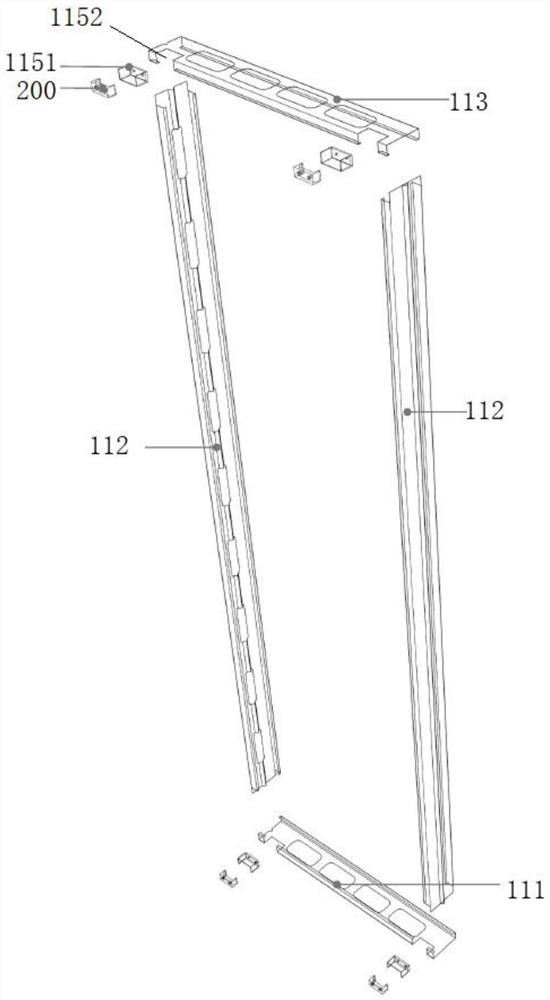

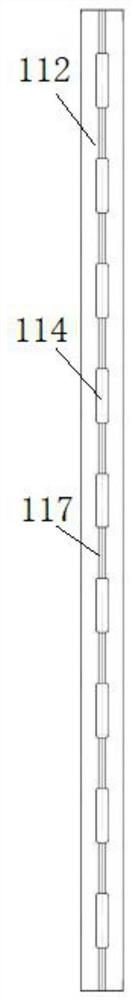

[0070] figure 1 , 2 They are respectively the schematic structural diagram and exploded view (including concrete connectors) of the peripheral components (including concrete connectors) of an easy-to-assemble lightweight wall panel provided in this embodiment, Figure 3-6 They are side views of an easy-to-assemble lightweight wall panel provided by this embodiment Figure 1 , front view and side view Figure II and back view. Such as Figure 1~6 As shown, the wall panel 100 includes a wall panel core 120, a peripheral member 110 and a connection port 115 for connecting with a building structure.

[0071] In the embodiment of the present application, it is defined that when the wallboard 100 is used to form a wall, the direction parallel to the height direction of the wall is the height direction of the wallboard 100, and the direction parallel to the width direction of the wall is the wallboard. In the width direction of 100 , the direction parallel to the thickness direc...

Embodiment 2

[0093] Based on the same inventive concept as an easy-to-assemble lightweight wallboard in the first embodiment, the present invention also provides a method for making an easy-to-assemble lightweight wallboard, which includes the following steps:

[0094] Step 1: Insert a built-in tube into a pair of through holes 113 aligned with the peripheral member 111;

[0095] Step 2: Put the peripheral component 111 into the mold of the wallboard core 120, and make the pouring port 114 upward;

[0096] Step 3: Pour the sheet material into the mold through the pouring port 114, and vibrate the side head 112 without the pouring port 114 below to discharge the air bubbles in the sheet material in the mold, thereby forming a dense wall Board core body 120;

[0097] Step 4: curing and demoulding to form the 100.

[0098] Specifically, the sheet material is an inorganic light-weight high-strength silicon compound, and the described inorganic light-weight high-strength silicon compound is a...

Embodiment 3

[0103] Based on the same inventive concept as the light-weight wall panel that is easy to assemble in the second embodiment, the present invention also provides a concrete frame structure wall system constructed by the wall panel 100 . In this implementation, the wall panel 100 is an interior wall panel.

[0104] Figure 16 It is a partial schematic diagram of the concrete frame structure wall (inner wall) system provided by this embodiment, as Figure 16 As shown, the concrete frame structure wall system includes the wall panel 100 and the concrete frame structure 300, the wall panel 100 is connected with the concrete frame structure 300 through the concrete connector 200, and the concrete connector 200 is slidably disposed in the fastener 1151 of the connecting port 115 .

[0105] Figure 17 is a structural schematic diagram of the concrete connector provided in this embodiment, such as Figure 17 As shown, the concrete connector 200 includes a fourth connecting plate 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com