Blowout preventer overhauling platform

A technology for overhauling platforms and blowout preventers, which is applied in drilling equipment, earth-moving drilling, drilling pipes, etc., can solve problems such as inability to lift cranes, hanging baskets, inconvenient overhaul, and high safety risks, so as to enhance construction safety and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

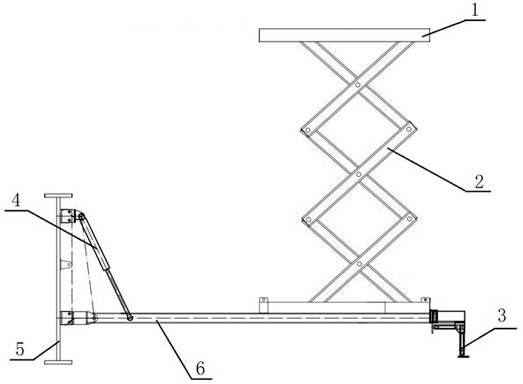

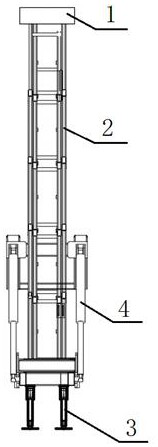

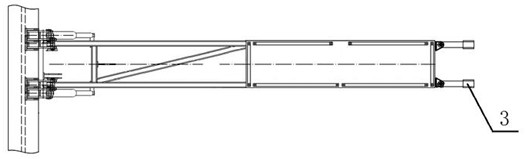

[0022] Embodiment 1, a blowout preventer maintenance platform, mainly composed of supporting legs 3, retractable arm 4, lifting base 6, arm frame 2 and working platform 1; The supporting leg 3 is installed at the other free end; the supporting leg 3 is hinged with the free end of the lifting base 6, and can freely rotate around the hinge axis to be perpendicular and parallel to the lifting base 6; one end of the retractable arm 4 is hinged with the lifting base 6 , the other end is provided with a hinged end with the derrick base 5, and the retractable arm 4 is a telescopic mechanism; when the retractable arm 4 is retracted, the lifting base 6 stands on the side of the derrick base 5, and the supporting legs 3 are recovered to be parallel to the lifting base 6 , when the retractable arm 4 is stretched out, the elevating base 6 is in a horizontal state, and the supporting leg 3 swings to be perpendicular to the free end of the elevating base 6; , the working platform 1 moves ve...

Embodiment 2

[0024] Embodiment 2, based on the basis of Embodiment 1, a group of connecting rods at the upper end of the boom 2 and the bottom of the working platform 1 form a sliding support through a chute, and a group of connecting rods at the lower end and the elevating base 6 pass through The rollers form a sliding support fit.

Embodiment 3

[0025] Embodiment 3, based on the basis of Embodiment 1, a group of connecting rods at the upper end of the boom 2 and the bottom of the working platform 1 form a sliding support through chute and rollers, and a group of connecting rods at the lower end and the lifting base 6 constitute sliding support cooperation by chute and roller above.

[0026] In the above embodiments, the telescoping mechanism is one of a hydraulic cylinder, a hydraulic cylinder or a linear drive screw. A safety valve is arranged in the pipeline of the hydraulic oil cylinder or the hydraulic cylinder. The safety valve includes one or more of a one-way valve, a flow regulating valve, a solenoid valve and an overflow valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com