Earth pressure TBM dual-mode dual-support heading machine and construction method

A technology of roadheaders and patterns, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of low construction efficiency, easy wear of the main drive seal, and difficulty in meeting construction requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide an earth pressure TBM double-mode double-support roadheader and a construction method, which can effectively improve construction efficiency, save costs, and have strong environmental adaptability.

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

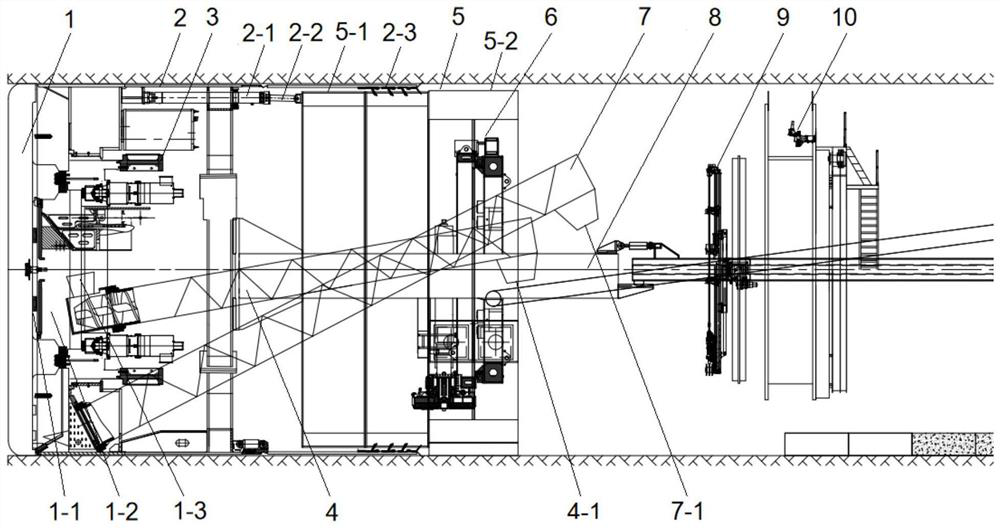

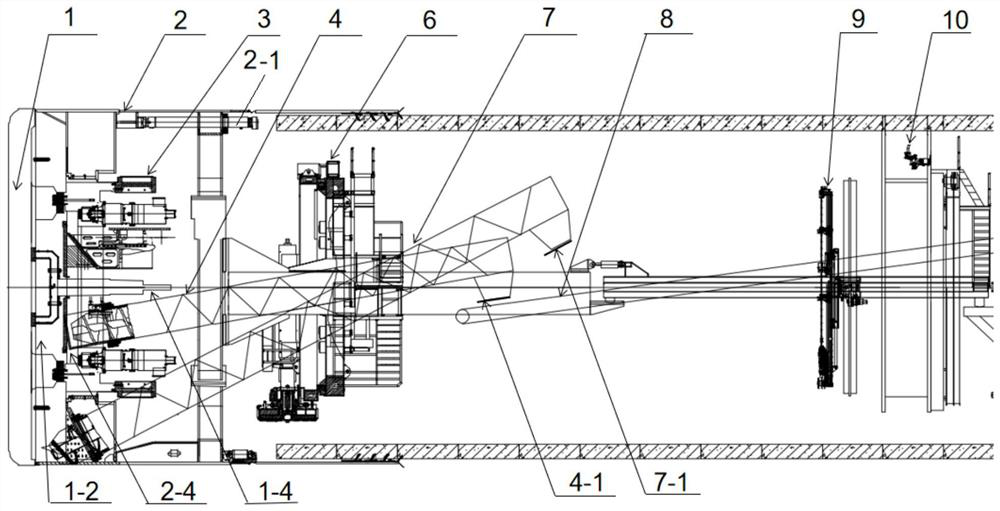

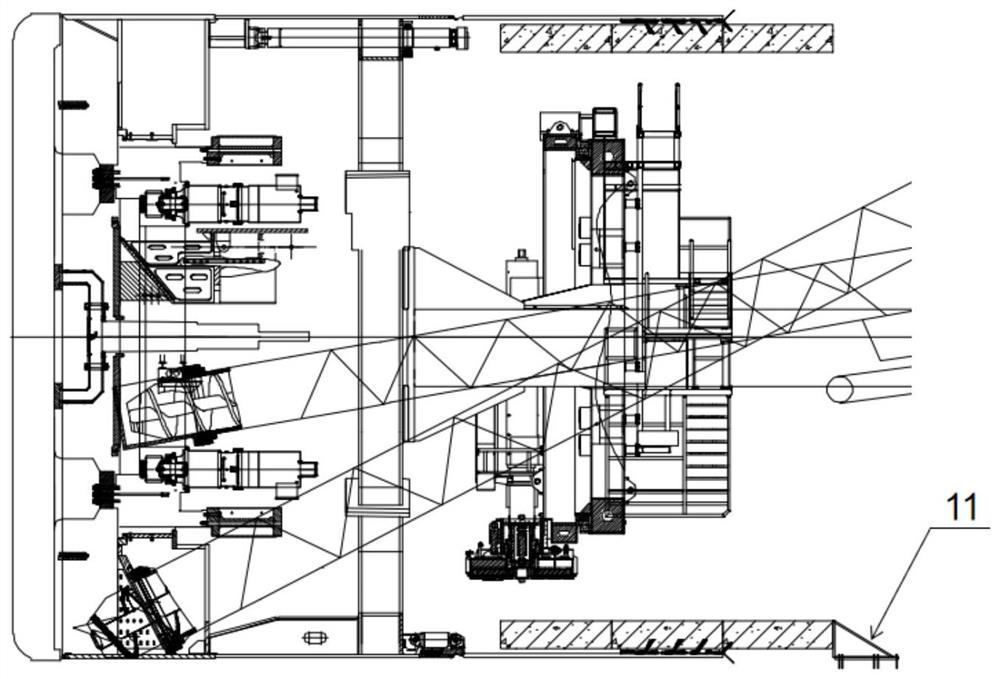

[0031] Please refer to Figure 1 to Figure 7 , figure 1 It is a structural schematic diagram of the TBM mode in a specific embodiment of the earth pressure TBM dual-mode dual-support roadheader provided by the present invention; figure 2 It is a structural schematic diagram under the earth pressure mode in a specific embodiment of the earth pressure TBM dual-mode double-support roadheader provided by the present invention; image 3 Schematic diagram of the structure of the segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com