Pantograph comprehensive geometric parameter online detection equipment and method based on laser projection

A geometric parameter and laser projection technology, applied in the field of rail transit, can solve the problems that the test results cannot cover the bow thickness, the measurement results have low precision and low precision, and achieve continuous online monitoring, good economic use value, and easy installation and debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

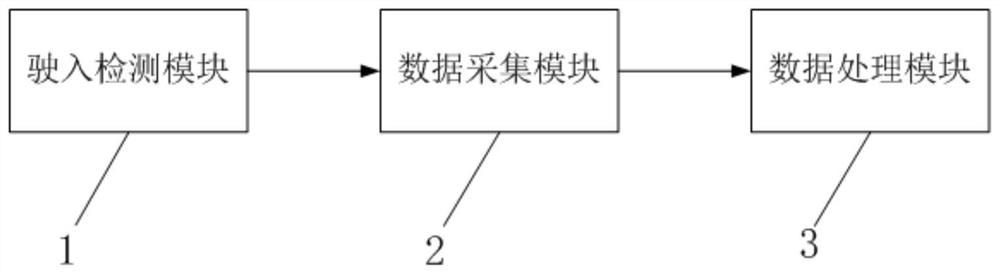

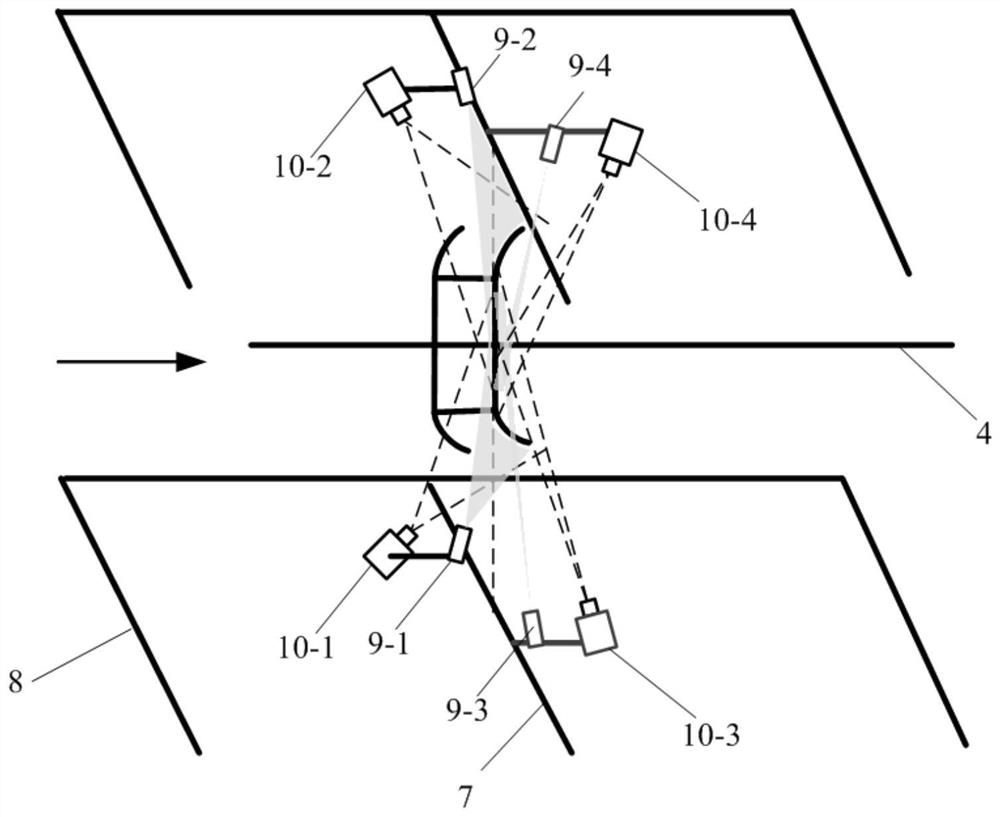

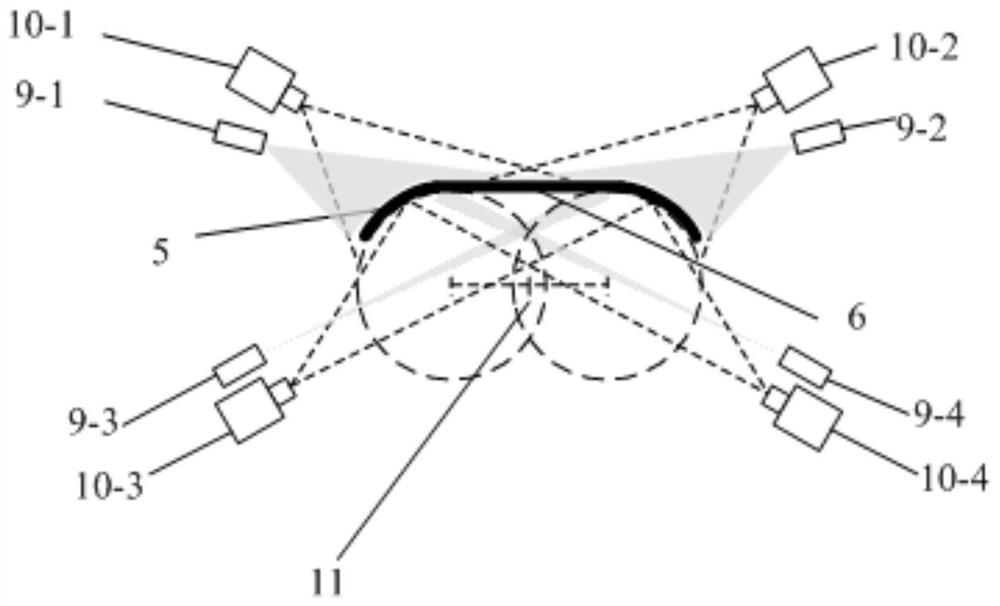

[0025] Such as Figure 1 ~ Figure 3 As shown, the present invention is based on the laser projection pantograph comprehensive geometric parameter on-line detection equipment, which includes the pantograph-catenary system, the pantograph-catenary system includes contacting catenary 4 and pantograph 5, and it also includes sequentially connected driving-in detection Module 1, data acquisition module 2, data processing module 3; entering detection module 1, for collecting the train entering signal when the train enters the detection area, and sending the train entering signal to data acquisition module 2; data acquisition module 2. It is used to collect the pantograph 5 image when receiving the train entering signal, and send the collected pantograph 5 image to the data processing module 3; the data processing module 3 is used to process the received pantograph 5 The images are processed to obtain geometric parameter data on the pantograph 5 .

[0026] Data collection module 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com