Soil cutter for preparing specific angle for remolded soil

A technology for reshaping soil from a specific angle, applied in the field of laboratory preparation and reshaping soil, which can solve problems such as mass loss and moisture content change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

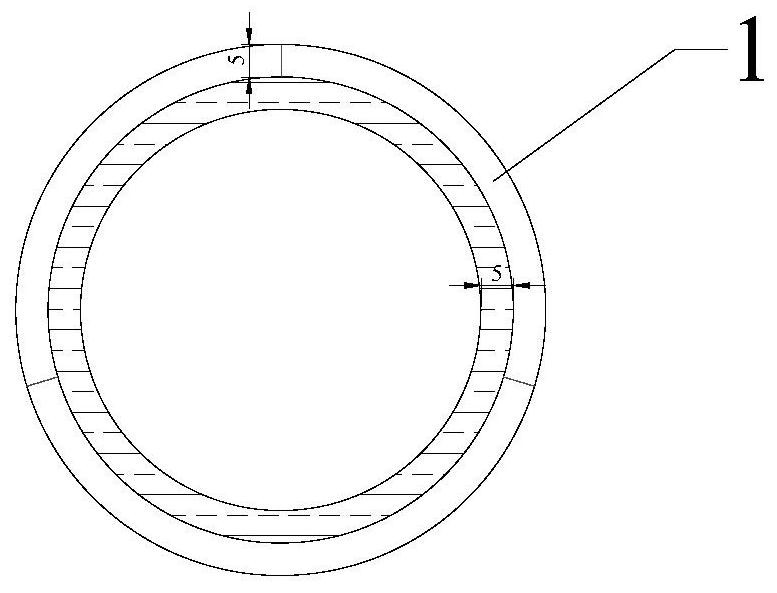

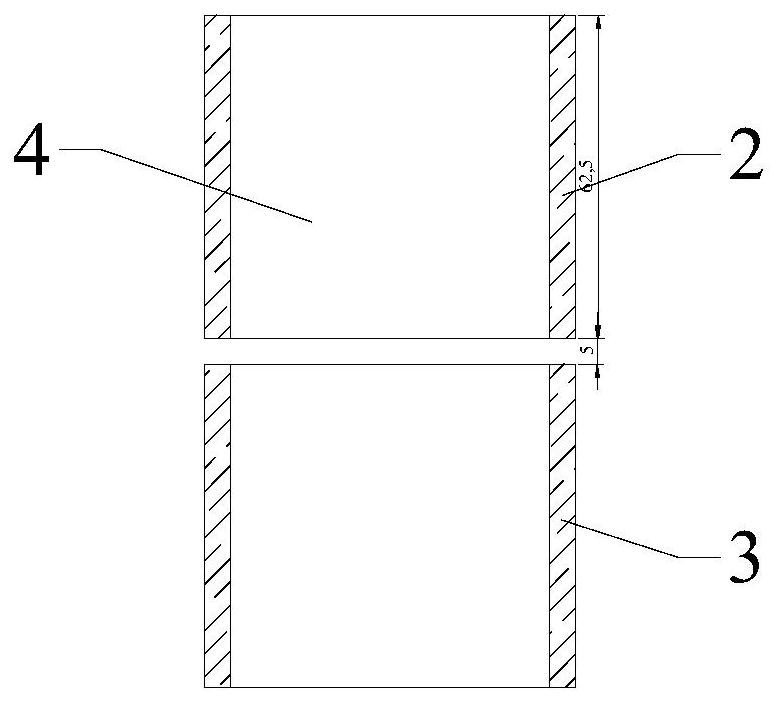

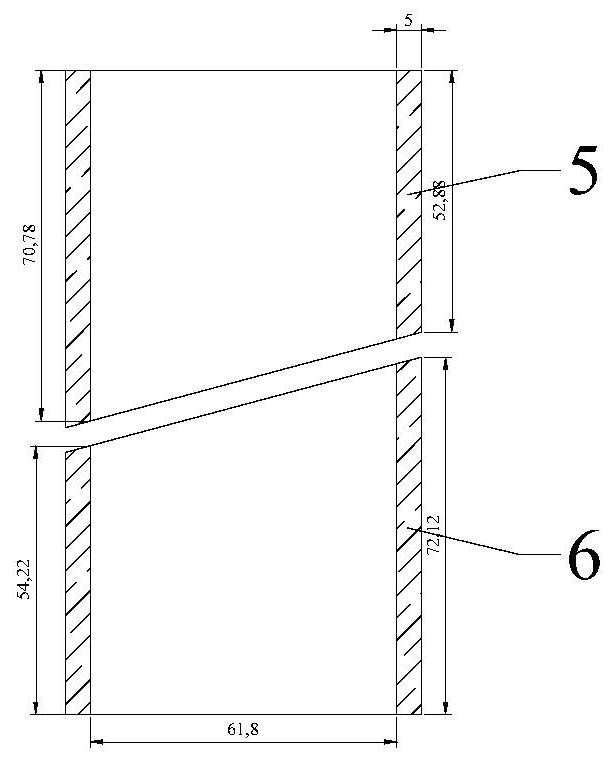

[0053] refer to figure 1 , Figure 4 , Figure 14 and Figure 15, the cutting angle of the present embodiment is 30 °, and the specific operation process is: 1) according to the original equipment of the laboratory, install the upper mold and the lower mold, and then place the outer ring 1, so that the outer ring 1 just embeds the upper mold and the lower mold 2) Put the soil sample 4 on the wooden board 29, and fix the guard plate 20 on the board 29 by screws 28. On the wooden board 29, move the rotating shaft 22 to the position where the scale line 18 on the first horizontal groove and the second horizontal groove is 30 degrees, turn the hand wheel 17 to reach the 30 degree of the dial 16, tighten the first nut 25, and fix the whole device 3) Put the steel wire 34 into the first vertical groove and the second vertical groove, screw on the upper cover 24, and cut the soil sample 4 through the steel wire 34.

Embodiment 2

[0055] refer to figure 1 , Figure 6 , Figure 14 and Figure 16 , the cutting angle of the present embodiment is 60 °, and the specific process is: 1) according to the original equipment of the laboratory, install the upper mold and the lower mold, and then place the outer ring 1, so that the outer ring 1 just embeds in the upper mold and the lower mold 2) Put the soil sample 4 on the plank 29, and fix the guard plate 20 on the plank by screws 28 On 29, move the rotating shaft 22 to the position where the scale line 18 on the first horizontal groove and the second horizontal groove is 60 degrees, turn the hand wheel 17 to reach 60 degrees of the dial 16, tighten the first nut 25 before and after, and fix the whole device 3) Put the steel wire 34 into the first vertical groove and the second vertical groove, screw on the upper cover 24, and cut the soil sample 4 through the steel wire 34.

Embodiment 3

[0057] refer to Figure 7 , Figure 8 and Figure 14 , the cutting angle of the present embodiment is 90 °, and the specific process is: 1) according to the original equipment of the laboratory, the upper mold and the lower mold are installed, and then the outer sleeve ring 1 is placed, wherein the outer sleeve ring 1 just embeds the upper mold and the lower mold The gap between the inner collar and the outer collar 1 forms a whole, brush paraffin, remove the outer collar 1 after making the soil sample 4; 2) put the soil sample 4 on the plank 29, and fix the guard plate 20 by screws 28 On the wooden board 29, move the rotating shaft 22 to the position where the scale line 18 on the first horizontal groove and the second horizontal groove is 90 degrees, turn the hand wheel 17 to reach the 90 degree of the dial 16, tighten the front and rear first nuts 25, and fix it The whole device; 3) put the steel wire 34 into the first vertical groove and the second vertical groove, screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com