Method for comparing stress relaxation resistance of metal material

A metal material, anti-stress technology, applied in the direction of analyzing materials, testing material hardness, using stable tension/pressure testing material strength, etc., to achieve the effect of saving experiment time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this example, Cu-Ni-Sn, Cu-Ni-Si, and Cu-Ni-Be alloys are used as examples to predict copper alloys with optimal stress relaxation resistance. The specific steps are as follows:

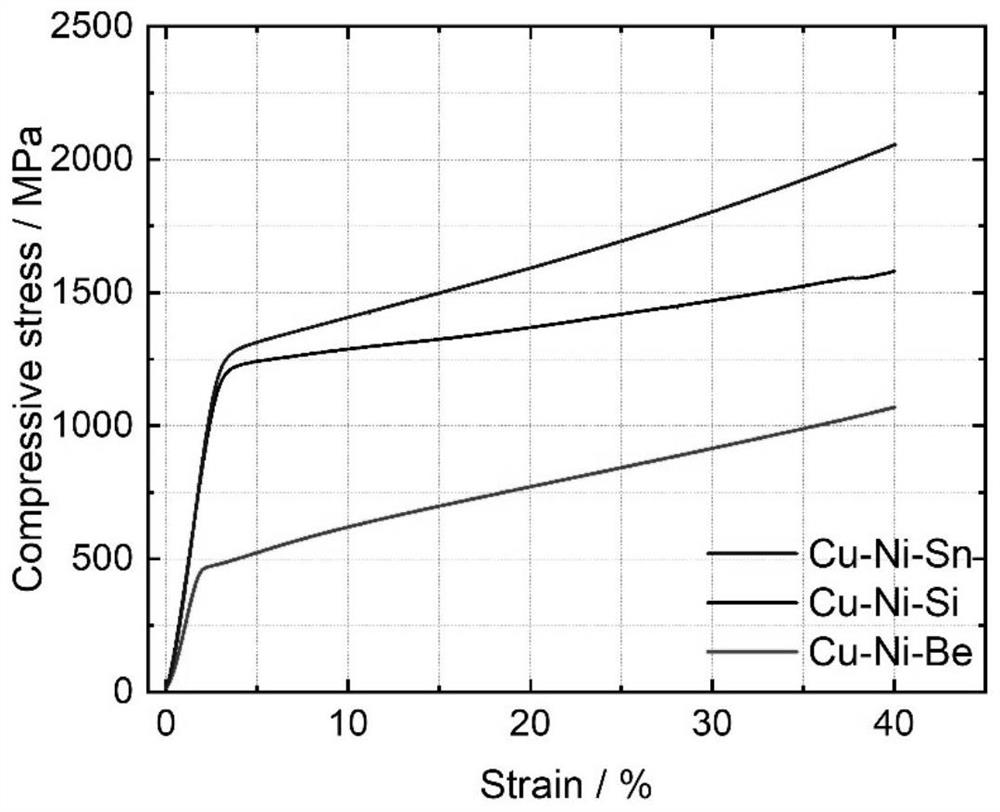

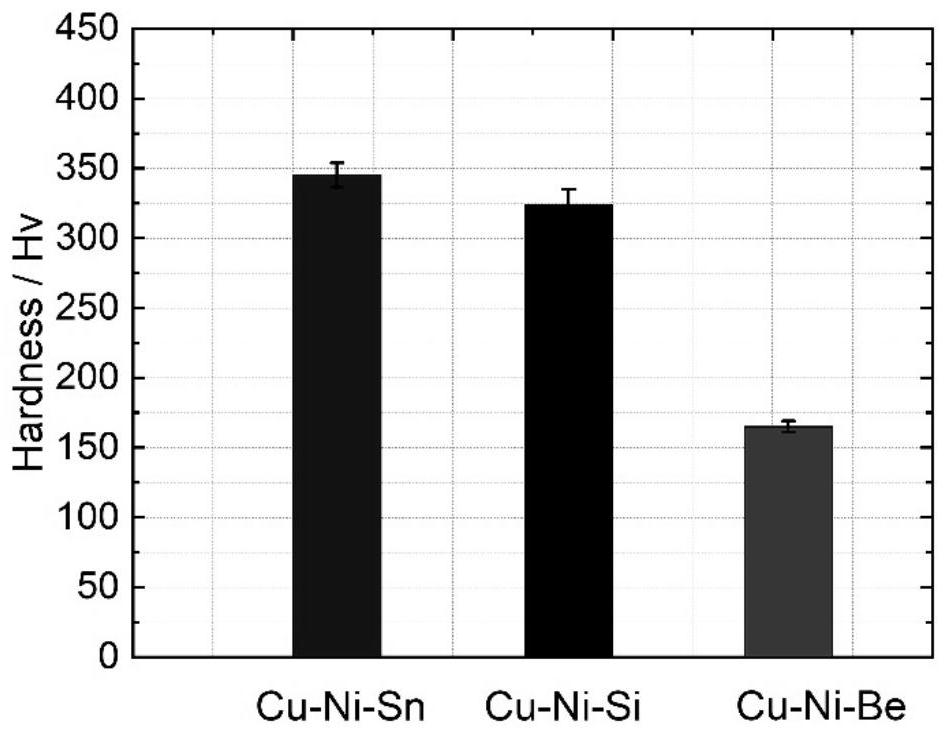

[0025] Step 1: Conduct quasi-static compression and Vickers indentation experiments at room temperature with a compression strain rate of 10 -3 the s -1 , the measured quasi-static compressive yield strength σ scs , and hardness HV (such as figure 1 and figure 2 shown);

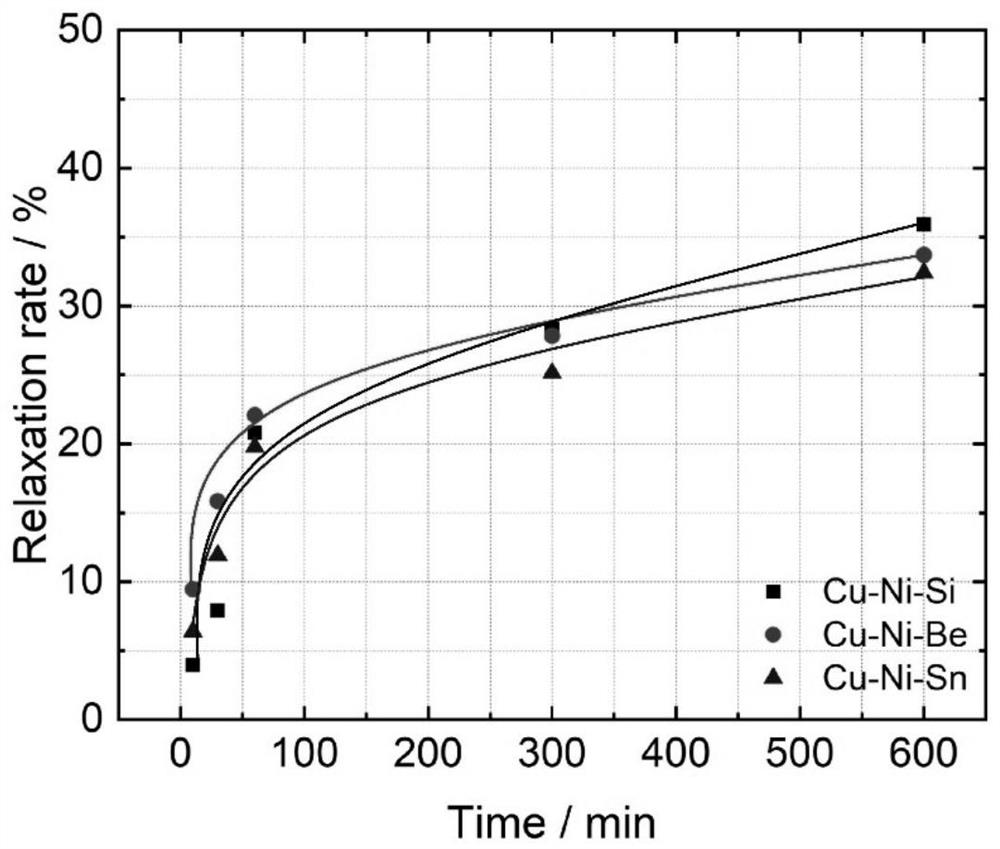

[0026] Step 2: Compare the compressive yield strength and Vickers hardness of the three copper alloys, wherein the copper alloy with the highest yield strength and hardness is the Cu-Ni-Sn alloy. However, in the stress relaxation test under the two conditions, the Cu-Ni-Sn alloy has the best stress relaxation resistance, and the prediction is consistent with the experimental results (reference Figure 3-5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com