Aluminum alloy and process for processing aluminum alloy plate

A processing technology, aluminum alloy technology, applied in the direction of metal rolling, etc., can solve the problems of unreasonable control of the type and amount of addition, unscientific processing technology of aluminum alloy sheet, low tensile strength, low elongation cupping value, etc. , to reduce the grain anisotropy, increase the lattice distortion energy, and increase the number of recrystallized nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

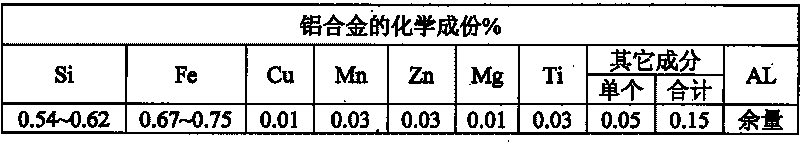

[0029] An aluminum alloy containing metallic iron and non-metallic silicon, the weight ratio of the metallic iron to non-metallic silicon is controlled between 1.0 and 1.5, and the aluminum alloy also contains metallic copper, manganese, zinc, magnesium, titanium. The weight percent contents of various elements in the aluminum alloy are respectively: 0.54% to 0.62% of silicon, 0.67% to 0.75% of iron, 0.01% of copper, 0.03% of manganese, 0.03% of zinc, The content of aluminum is 0.03%, the content of magnesium is 0.01%, the content of titanium is 0.03%, the content of impurities is less than 0.15%, and the rest is aluminum.

Embodiment 2

[0031] The present invention also provides a processing technology for an aluminum alloy thin plate, the process comprising the following processing steps:

[0032] The first step: batching, according to the batching element variety and proportioning ratio described in embodiment 1, the raw materials are configured;

[0033] The second step: smelting, the configured raw materials are added to the smelting furnace according to the set procedure to smelt into liquid aluminum alloy;

[0034] The third step: casting and rolling, using twin-roller continuous casting and rolling equipment to directly cast and roll the liquid aluminum alloy into a cast-rolled slab with a thickness of 6.0 mm to 10.0 mm suitable for cold rolling;

[0035] The fourth step: cold rolling, through five to six cold rolling processes, the cast and rolled thin slab is rolled into a 0.38mm cold rolled plate;

[0036] The fifth step: Foil rolling, through two foil rolling processes, the cold-rolled material af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com