Power transformation equipment defect detection method based on sensitive position dependence analysis

A technology of defect detection and dependent analysis, which is applied in the direction of material analysis, image analysis, optical testing for flaws/defects, etc. It can solve problems such as high false detection rate, inaccurate detection results, and failure to consider the correlation of relevant factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

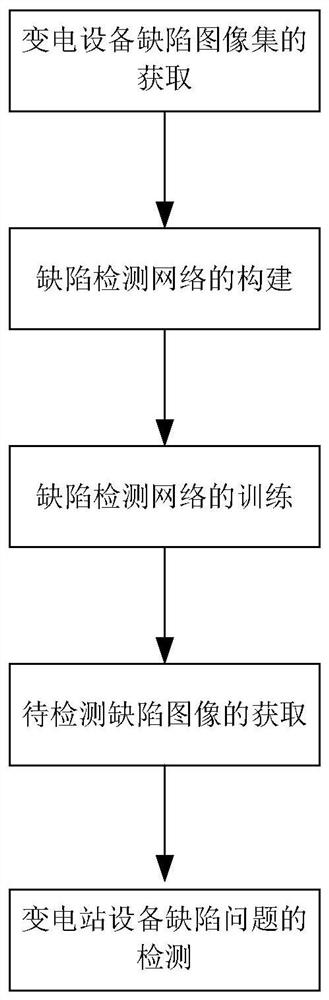

[0053] Such as figure 1 As shown, a method for detecting defects of substation equipment based on sensitive position-dependent analysis described in the present invention includes the following steps:

[0054] The first step is the acquisition of electrical equipment defect image sets: acquire several substation equipment defect images to form a substation defect image dataset, which includes meter damage images, insulator rupture images, silica gel discoloration images, oil seal damage images, and high-altitude suspended object images , bird's nest image, ground oil image, metal corrosion image.

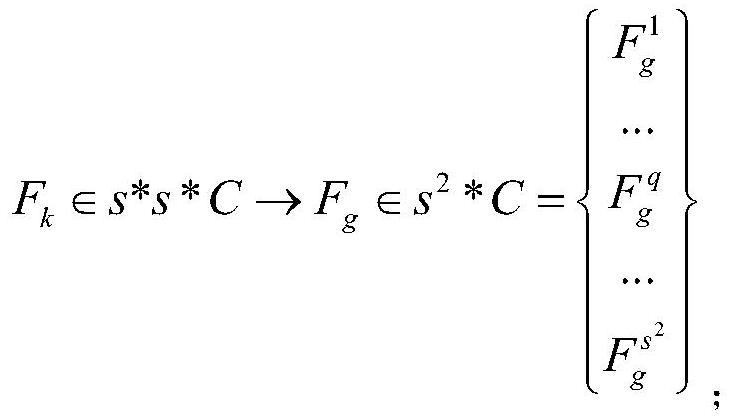

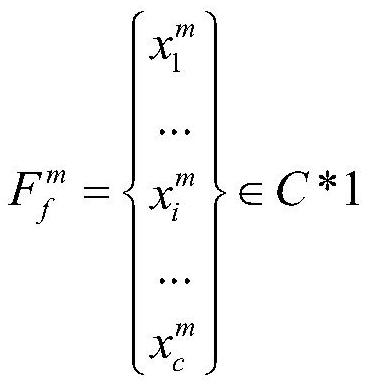

[0055] The second step is to construct a defect detection network: construct a defect detection network, and the defect detection network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com