Linear coil inductor formed by continuously winding flat wire of electronic component

A technology of electronic components and coil inductance, applied in the direction of transformer/inductor cooling, electrical components, electrical component structure association, etc., can solve problems such as explosion, component damage, and internal temperature cannot be dissipated in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

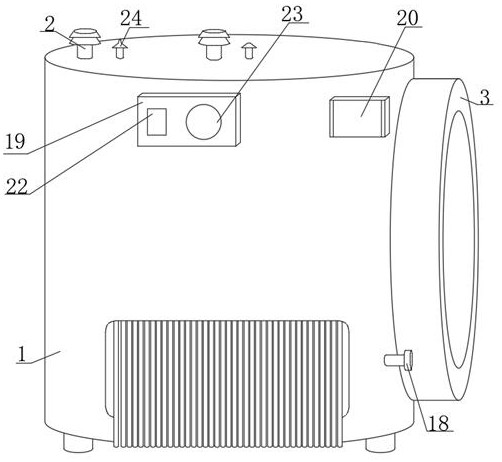

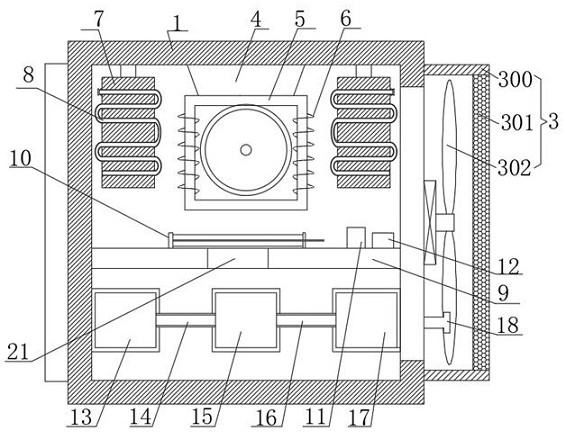

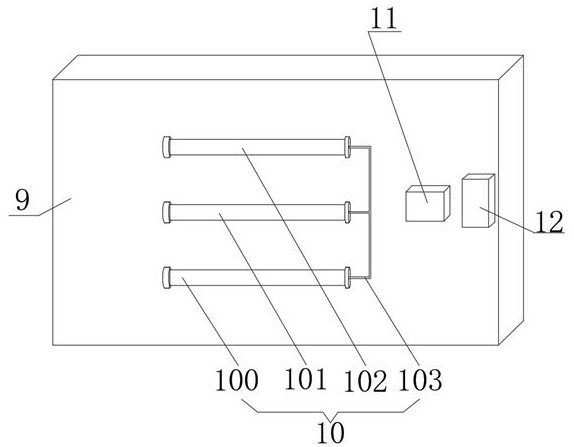

[0025] Embodiment one, such as figure 1 and 2 As shown, the present invention provides a technical solution: a linear coil inductor wound with flat wires of electronic components, including an inductor body 1, and the top of the inductor body 1 is fixedly installed with a first external terminal 2 and a terminal 24. The right side of the inductor body 1 is fixedly installed with a heat dissipation mechanism 3, the inner wall of the top of the inductor body 1 is fixedly installed with a second external terminal 4, and the bottom end of the second external terminal 4 is fixedly connected with a magnetic core 5, and the magnetic core The surface of 5 is wound with a winding wire group 6, the inner wall of the top of the inductor body 1 is fixedly connected with a heat sink 7, and the front of the heat sink 7 is fixedly connected with a condenser 8, and the inner wall of the inductor body 1 is provided with a plate 9, And the top of the board 9 is fixedly installed with a fuse 10...

Embodiment 2

[0029] Embodiment two differs from embodiment one in that: as Figure 1-4 , the present invention provides a technical solution: a linear coil inductor wound with a flat wire of an electronic component, comprising an inductor body 1, a first external terminal 2 and a terminal 24 are fixedly installed on the top of the inductor body 1, The right side of the inductor body 1 is fixedly installed with a heat dissipation mechanism 3, the inner wall of the top of the inductor body 1 is fixedly installed with a second external terminal 4, and the bottom end of the second external terminal 4 is fixedly connected with a magnetic core 5, and the magnetic core 5 The surface is wound with a winding wire group 6, the inner wall of the top of the inductor body 1 is fixedly connected with a heat sink 7, and the front of the heat sink 7 is fixedly connected with a condenser 8, and the inner wall of the inductor body 1 is provided with a plate 9, and is A fuse 10, a voltage detector 11 and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com