Anti-frosting non-hydrogenated chocolate and preparation method thereof

A non-hydrogenated, chocolate technology, applied in cocoa, food science, applications, etc., can solve the problem of non-hydrogenated chocolate frosting and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

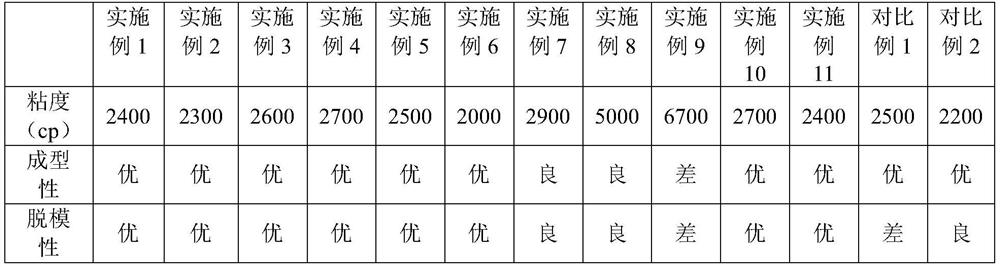

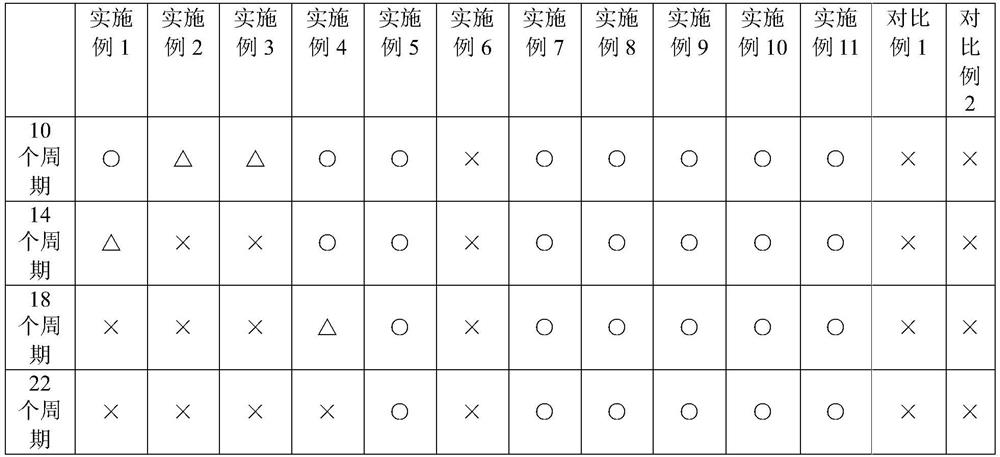

Examples

preparation example Construction

[0052] The present invention also provides a preparation method of anti-blooming non-hydrogenated chocolate, the preparation method comprising:

[0053] Weigh the corresponding weight of non-hydrogenated vegetable oil A and non-hydrogenated vegetable oil B, mix the two, heat to 50-60°C for dissolution, and cool to 40-45°C after complete dissolution to obtain the oil mixture;

[0054] Take part of the oil mixture and put it into a chocolate fine grinder, then put sugar, milk powder, maltodextrin and part of phospholipids into the chocolate fine grinder, and grind at 40-45°C to obtain a mixed material;

[0055] Then put the remaining part of the oil mixture, phospholipid and essence into the chocolate refiner and mix with the mixed material to obtain a mixed slurry. In this embodiment, the viscosity of the chocolate slurry is controlled by adding oil and phospholipid, so that it can be used later. It is easier to pour chocolate mass into chocolate moulds;

[0056] Cool the resu...

Embodiment 1

[0063] Embodiment 1, the weight of all raw materials is based on 100 parts, and the non-hydrogenated chocolate includes the raw materials of the following parts by weight:

[0064] 34-39 parts of white sugar, 19.8 parts of non-hydrogenated vegetable oil A, 19.8 parts of non-hydrogenated vegetable oil B, 8-8.8 parts of skimmed milk powder, 10-12 parts of whey powder, 1.7-2.3 parts of whole milk powder, 4.37 parts of maltodextrin, phospholipids 0.3 parts, essence 0.03 parts.

Embodiment 2

[0065] Embodiment 2 is different from the foregoing embodiments in that the non-hydrogenated chocolate includes the following raw materials in parts by weight:

[0066] 13 parts of non-hydrogenated vegetable oil A, 26.5 parts of non-hydrogenated vegetable oil B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com