Extruder for making self-heating rice

A technology of extruder and self-heating rice, applied in food forming, food science, application, etc., can solve the problems of high temperature of rice grains, unfavorable rice grains, easy to stick and form agglomerates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

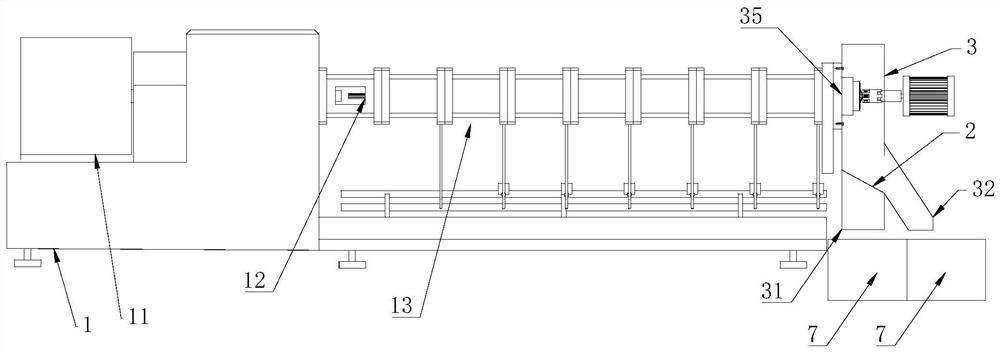

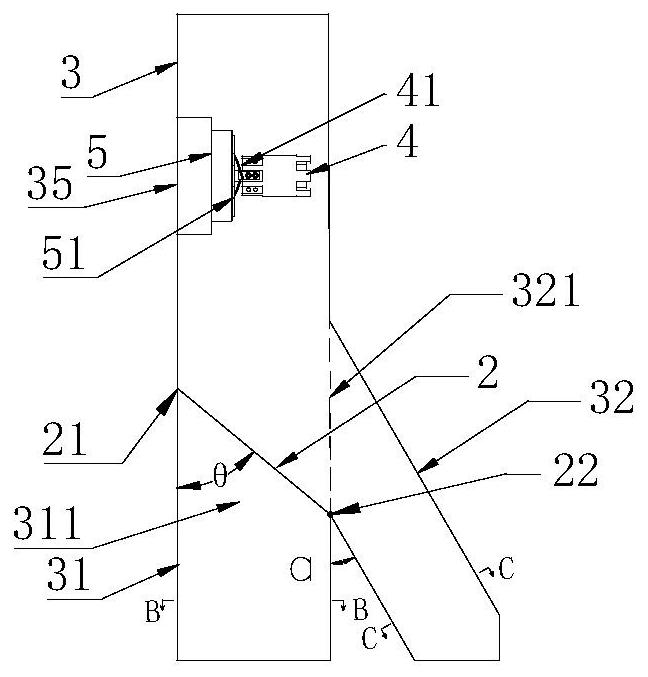

[0043] An extruder for making self-heating rice, such as figure 1 and Figure 4 As shown, it includes a machine base 1, a motor 11 arranged in the machine base 1, an extrusion screw 12 power-connected with the motor 11, and an extrusion cavity 13 sleeved outside the extrusion screw 12. The extrusion cavity 13 includes a feed part and a transport part in turn, the feed part is provided with a feed port, the end of the extrusion cavity 13 is provided with an extrusion die 5, and the extrusion screw 12 cooperates with the extrusion die 5 to Material extrusion molding, the extrusion port 51 of the extrusion die 5 is provided with a shearing mechanism 4, and the extrusion die 5 is also provided with a protective cover 3, and the protective cover 3 will extrude the extrusion die 5 and The shearing mechanism 4 is covered in it, and the bottom of the protective cover 3 is provided with at least two discharge passages, the discharge passages are arranged below the extrusion port 51 of...

Embodiment approach 2

[0048]The difference between this embodiment and Embodiment 1 is that a diversion plate and a fan are also arranged on the protective cover, and the structure of the discharge channel is also slightly different.

[0049] Such as Figure 5 and Figure 6 As shown, the inner wall of the protective cover 3 is provided with a first baffle 33 and a second baffle 34, and the two baffles are all arranged outside the rotation area of the baffle plate 2, and the first baffle 33 is arranged on the first Above the discharge channel 31, the second flow guide plate 34 is arranged above the second discharge channel 32, the first flow guide plate 33 is inclined downward, and its inclined direction is toward the second discharge channel 32, the The first baffle 33 is arranged on the inner wall where the slit 35 is located, and the second baffle 34 is arranged on the inner wall of the protective cover 3 on the opposite side of the first baffle 33, and the second baffle 34 is also inclined do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com