Beta-carotene embedding emulsion based on soybean peptide aggregates and preparation method thereof

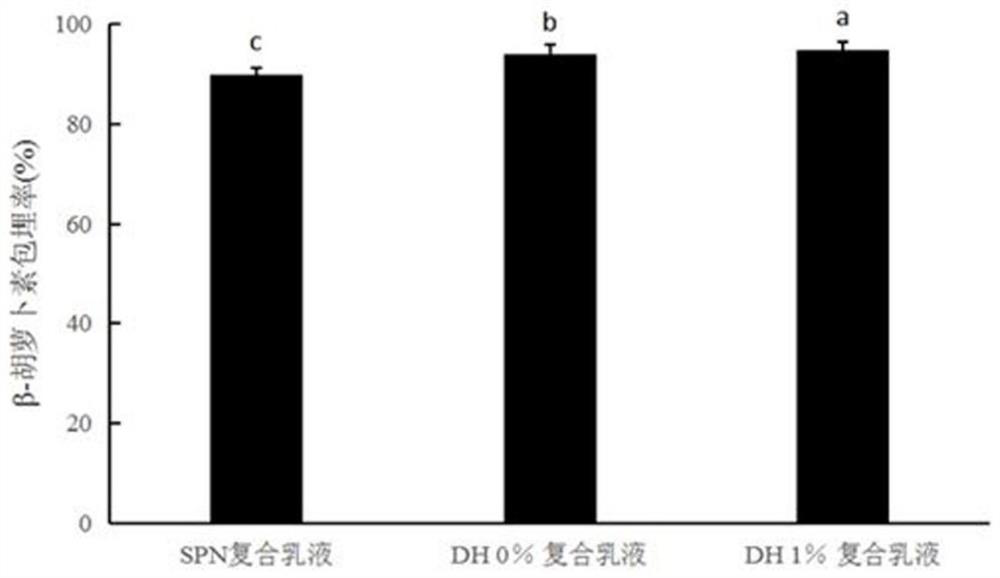

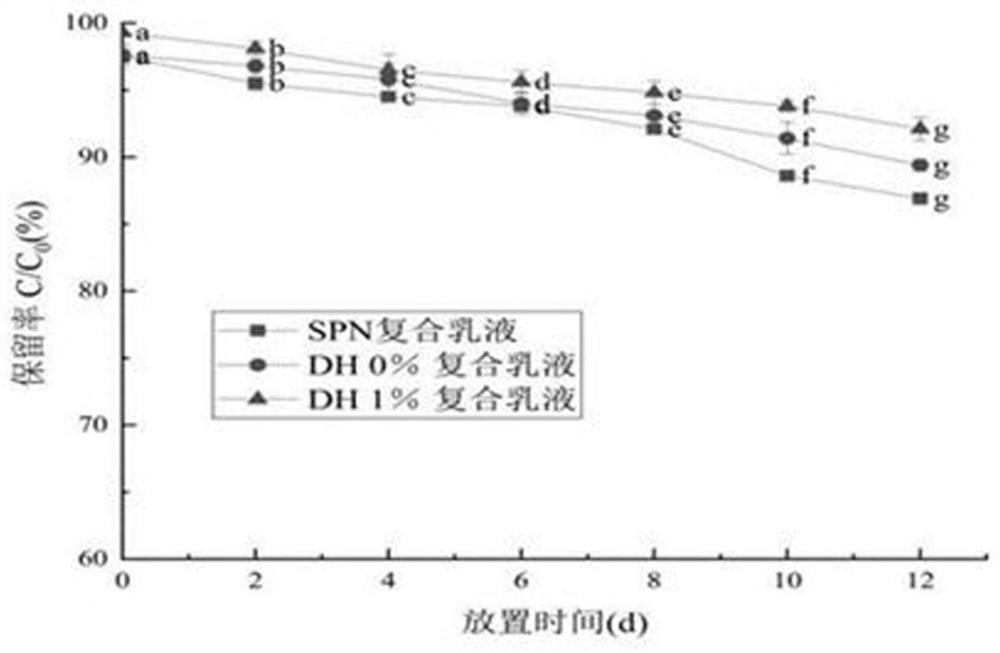

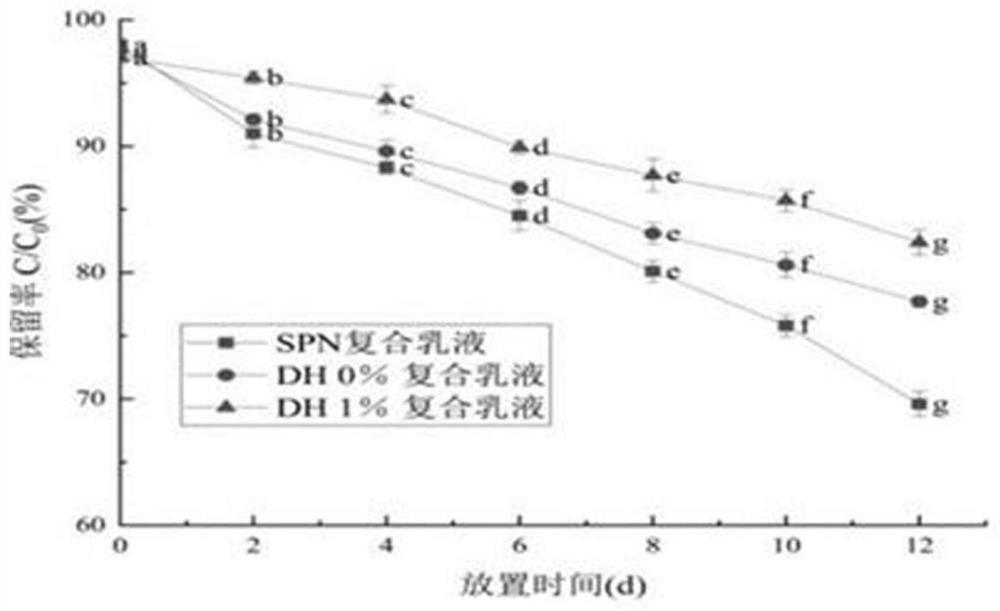

A technology of carotene and soybean peptide, applied in the direction of food ingredients as emulsifiers, food science, application, etc., can solve the problems of consumer inconvenience, reduced applicability, and vulnerability to losses, and achieve the improvement of antioxidant capacity, emulsifying activity and Improvement of emulsification stability and improvement of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Soybean protein isolate solution was stirred at a solid-liquid ratio of 1:20g / mL for 2 hours, then hydrated overnight, and heated at 90°C for 15 minutes to adapt to denaturation and facilitate enzymatic hydrolysis. Then it was hydrolyzed at 55°C and pH 8.0 for 6h. After enzymatic hydrolysis, treat at 100°C for 5 minutes, immediately adjust the pH to 7.0 in an ice bath to room temperature, and centrifuge at 4000 rpm / min for 15 minutes to obtain soybean peptide aggregates (SPA), wash twice with water, redisperse, and freeze-dry. The SPA solution was magnetically stirred at room temperature for 2 h, then placed at 4°C overnight to fully hydrate, and the pH was adjusted to 7.0 with 0.1 mol / L NaOH or HCl. Ultrasonic treatment was performed under the conditions of ultrasonic power 150W and output frequency 20kHz. Centrifuge at 8000rpm / min for 10min after the ultrasonication to remove a small amount of insoluble precipitate, and the obtained particle solution is soybean p...

Embodiment 2

[0035] (1) Soybean protein isolate solution was stirred at a solid-liquid ratio of 1:20g / mL for 2 hours, then hydrated overnight, and heated at 90°C for 15 minutes to adapt to denaturation and facilitate enzymatic hydrolysis. Then it was hydrolyzed at 55°C and pH 8.0 for 6h. After enzymatic hydrolysis, treat at 100°C for 5 minutes, immediately adjust the pH to 7.0 in an ice bath to room temperature, and centrifuge at 4000 rpm / min for 15 minutes to obtain soybean peptide aggregates (SPA), wash twice with water, redisperse, and freeze-dry. The SPA solution was magnetically stirred at room temperature for 2 h, then placed at 4°C overnight to fully hydrate, and the pH was adjusted to 7.0 with 0.1 mol / L NaOH or HCl. Ultrasonic treatment was performed under the conditions of ultrasonic power 150W and output frequency 20kHz. Centrifuge at 8000rpm / min for 10min after the ultrasonication to remove a small amount of insoluble precipitate, and the obtained particle solution is soybean p...

Embodiment 3

[0042] (1) Soybean protein isolate solution was stirred at a solid-liquid ratio of 1:20g / mL for 2 hours, then hydrated overnight, and heated at 90°C for 15 minutes to adapt to denaturation and facilitate enzymatic hydrolysis. Then it was hydrolyzed at 55°C and pH 8.0 for 6h. After enzymatic hydrolysis, treat at 100°C for 5 minutes, immediately adjust the pH to 7.0 in an ice bath to room temperature, and centrifuge at 4000 rpm / min for 15 minutes to obtain soybean peptide aggregates (SPA), wash twice with water, redisperse, and freeze-dry. The SPA solution was magnetically stirred at room temperature for 2 h, then placed at 4°C overnight to fully hydrate, and the pH was adjusted to 7.0 with 0.1 mol / L NaOH or HCl. Ultrasonic treatment was performed under the conditions of ultrasonic power 150W and output frequency 20kHz. Centrifuge at 8000rpm / min for 10min after the ultrasonication to remove a small amount of insoluble precipitate, and the obtained particle solution is soybean p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com