Dustproof crushing device for construction waste recycling

A construction waste and crushing device technology, applied in the field of construction, can solve the problems of affecting the working environment, easily generating a lot of dust, and the crushing effect of construction waste is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

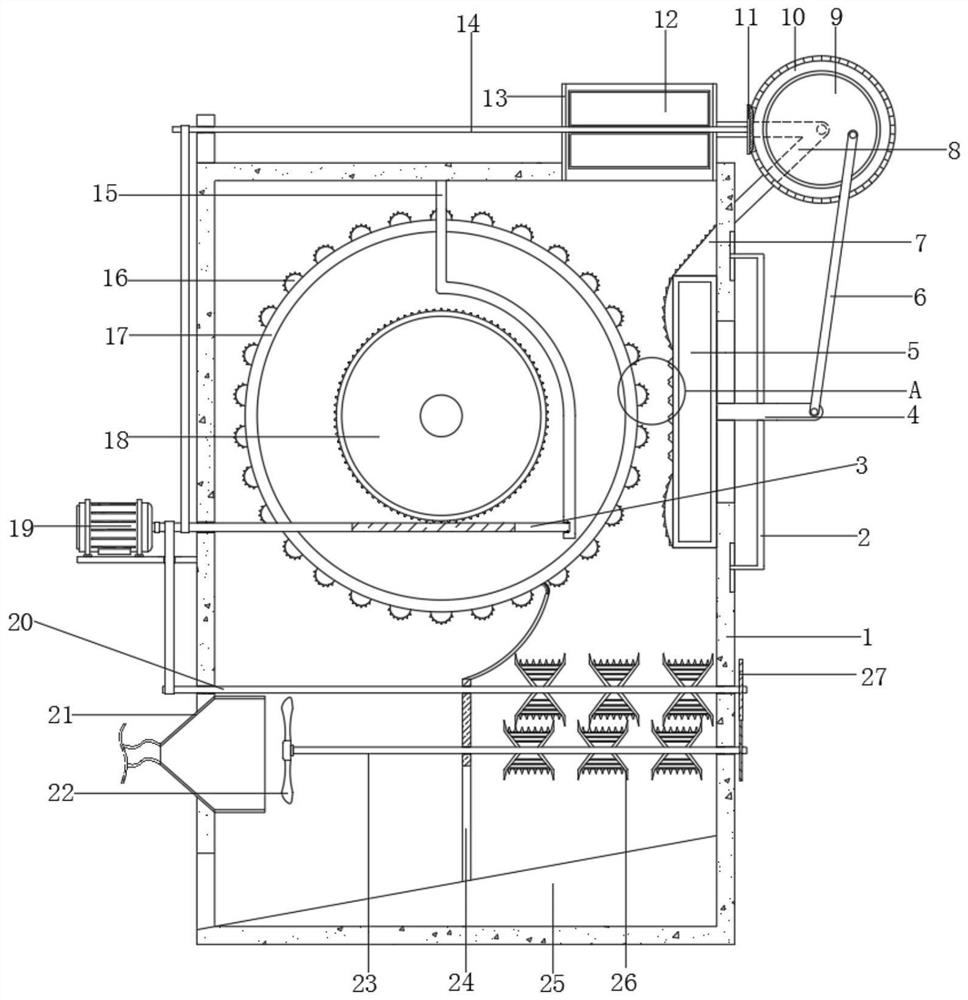

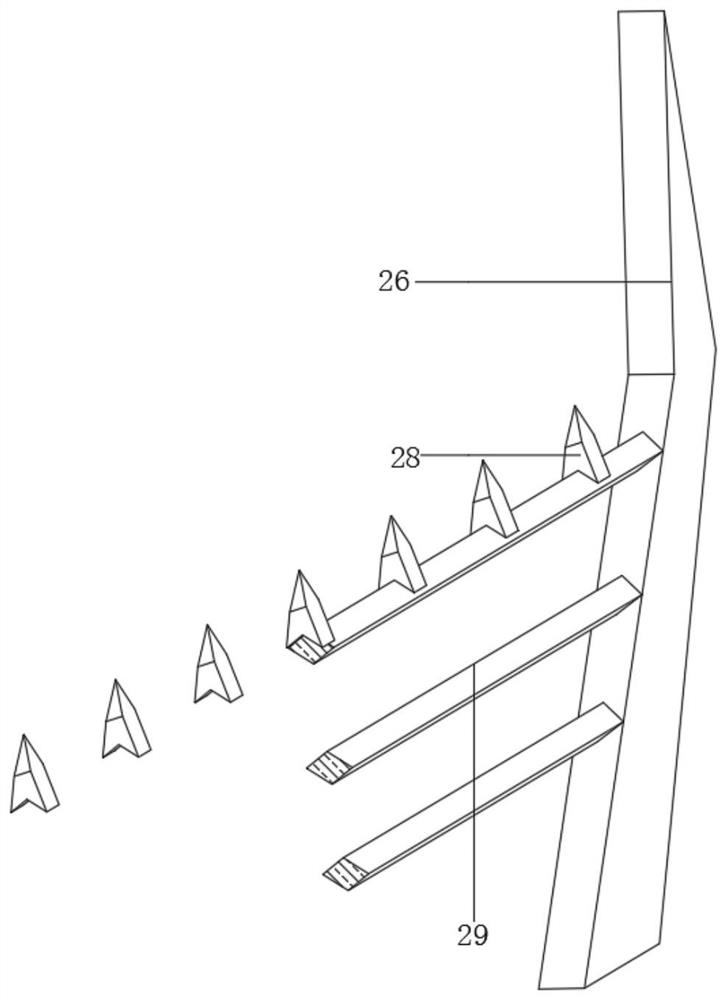

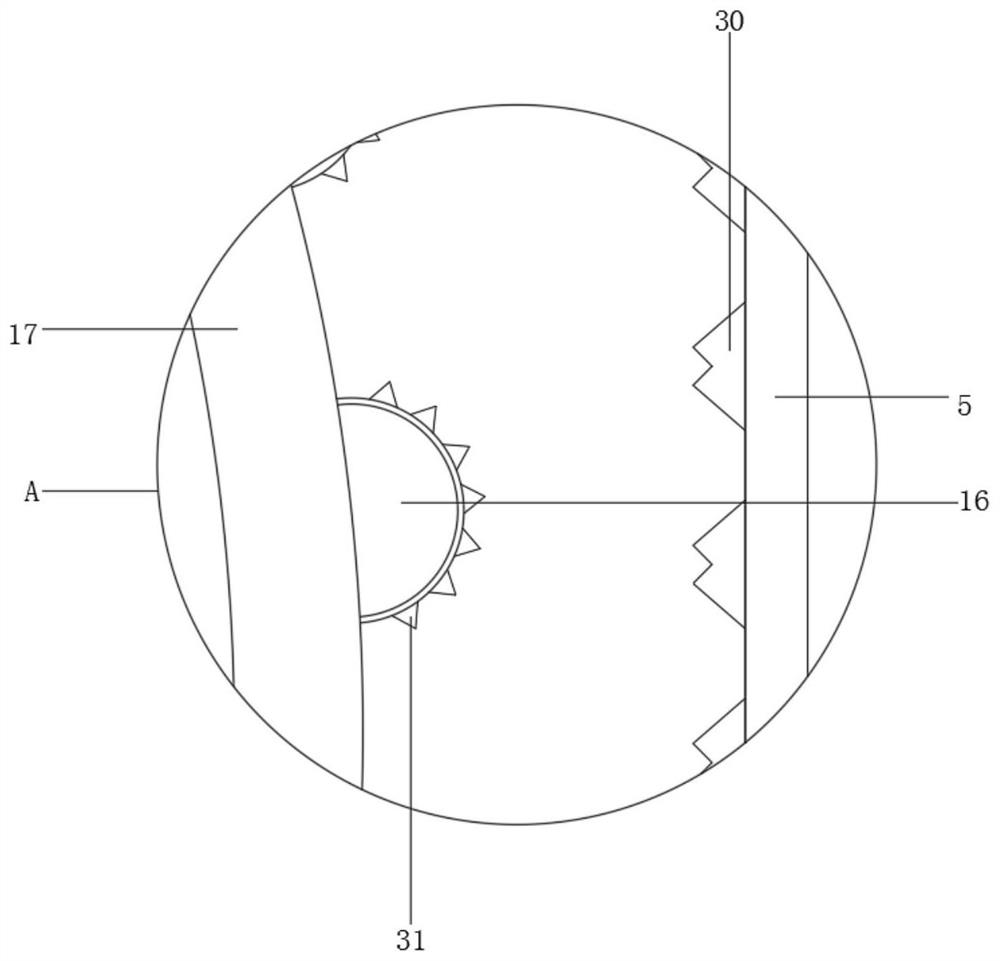

[0030] refer to Figure 1-5 , a dust-proof crushing device for recycling construction waste, comprising a casing 1, a feeding hopper 13 is welded on the top of the casing 1, a shaft column is rotatably connected to the end of the casing 1 near the top through a bearing, and the outer wall of the shaft column is connected by a key There is a roller 17, the outer wall of the roller 17 is welded with convex strips 16 distributed at equal distances, and the side of the casing 1 close to the roller 17 is provided with a pressing mechanism, and the pressing mechanism includes a side of the casing 1. The end arm 4 is slidably connected to the inner wall of the sliding groove, and a cube-shaped rubbing block 5 is welded on one side of the end arm 4, and the rubbing block 5 is welded with equidistantly distributed rubbing blocks 5 on the side close to the roller 17. The kneading concave teeth 30 have a trapezoidal structure as a whole, the top outer wall of the rubbing block 5 is welde...

Embodiment 2

[0041] refer to figure 1 and Image 6 , a dust-proof crushing device for recycling construction waste. Compared with Embodiment 1, this embodiment also includes an arc end block 34 welded to both ends of one side of the rubbing block 5, and the arc end block 34 and the material guide top block 7 The outer walls of each are welded with diamond-shaped blocks 35 distributed equidistantly; some waste materials can be in contact with the top block 7 of the guide material during the input process, and the diamond-shaped blocks 35 are used to realize pre-crushing treatment, and the arc-end blocks 34 and the diamond-shaped blocks on their surfaces Block 35 can cooperate with the reciprocating operation of rubbing block 5 itself up and down, improving the extrusion effect with roller 17.

[0042] When the present invention is in use: the set arc end block 34 and the rhombus block 35 on the arc end block 34 and the top block 7 of the guide material, part of the waste material can conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com