Cutting steel wire cleaning device for double-station multi-wire cutting machine

A multi-wire cutting machine and a technology for cutting steel wires. It is applied in the direction of abrasive surface adjustment devices, grinding/polishing safety devices, and manufacturing tools. It can solve problems such as inability to ensure straight cuts, affecting product quality and cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

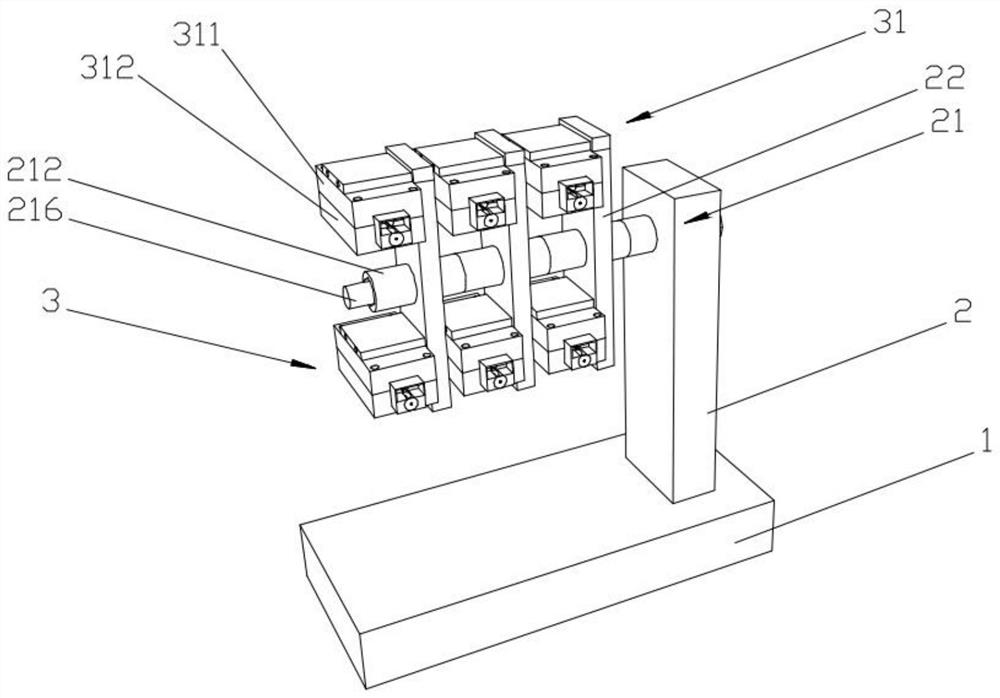

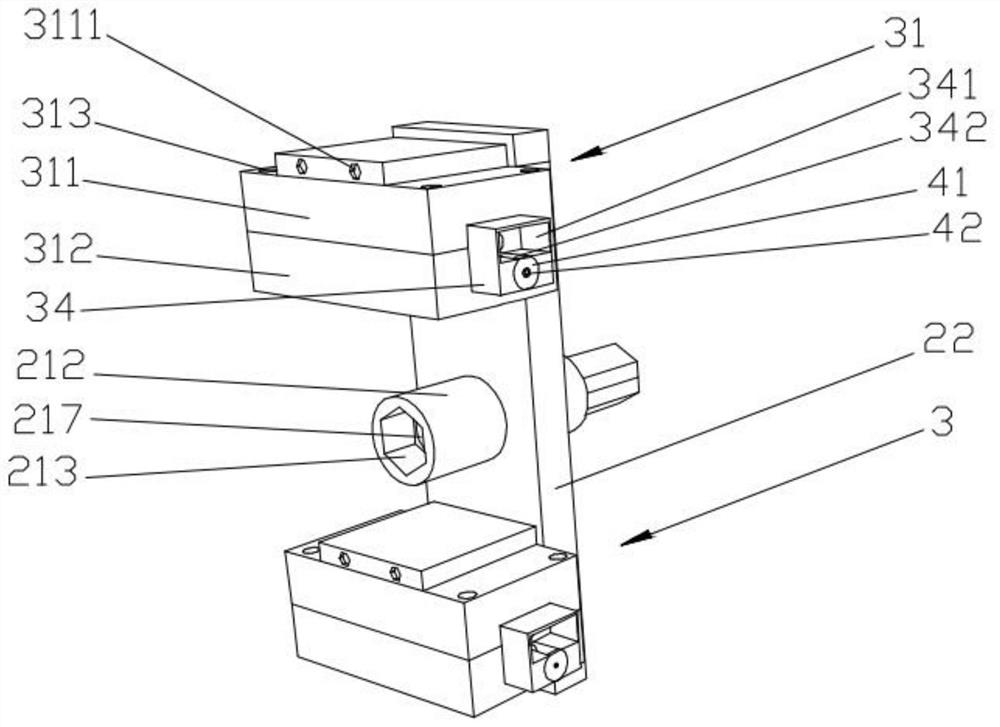

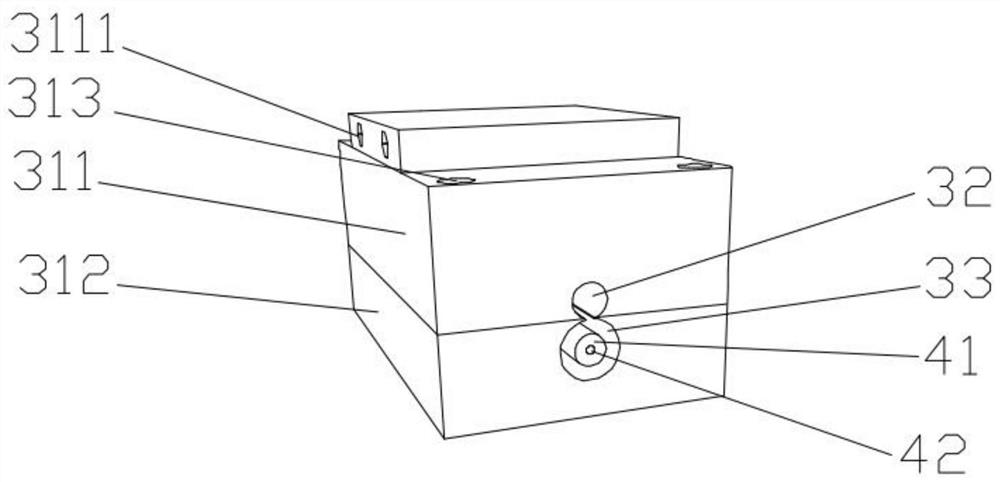

[0028] Such as Figure 1-8 As shown, it is a cutting steel wire cleaning device for a double-station multi-wire cutting machine in this embodiment, including a movable base 1, a support column 2 is arranged on the movable base 1, and a rotating shaft is fixedly arranged on the side wall of the support column 2. The shaft 21 and the outer space of the rotating shaft 21 are provided with several adjustment plates 22, and the two ends of the adjustment plates 22 are provided with a cutting steel wire box device 3, and the cutting steel wire box device 3 includes an outer box body 31, and the outer box body 31 is provided with On the adjusting plate 22, a wiring trough 32 and a dust collection trough 33 are arranged in sequence from top to bottom in the outer box body 31, and the inner wall of the wiring trough 32 is provided with a brush with a matching sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com