Multi-axis machining center with automatic feeding and discharging functions

A technology of automatic loading and unloading, multi-axis processing, applied in stone processing equipment, stone processing tools, metal processing equipment and other directions, can solve the problem of inconvenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

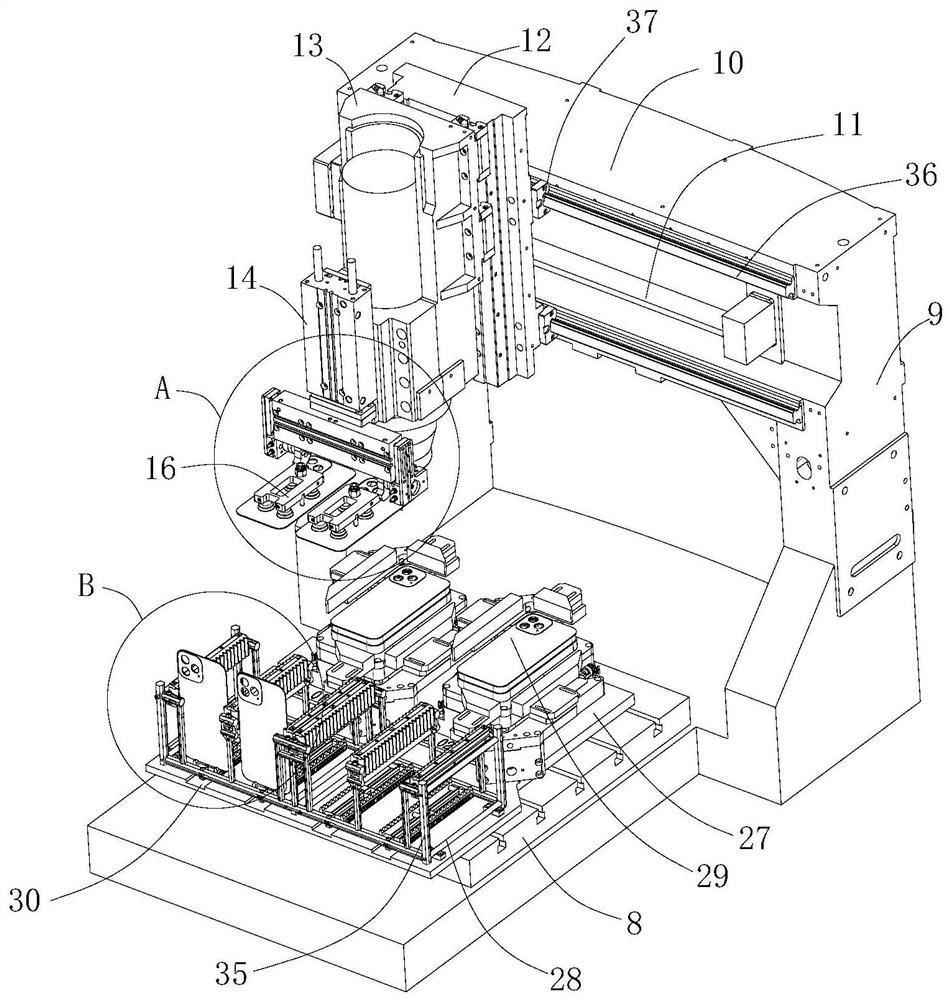

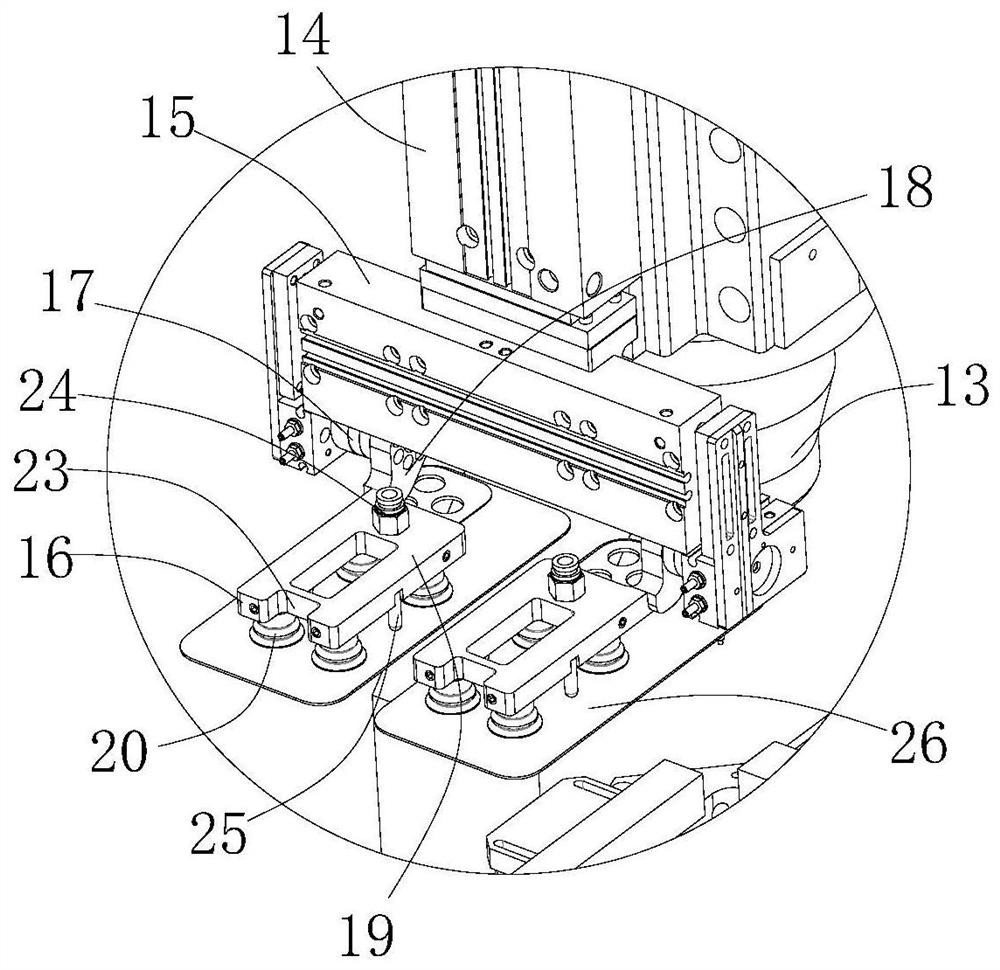

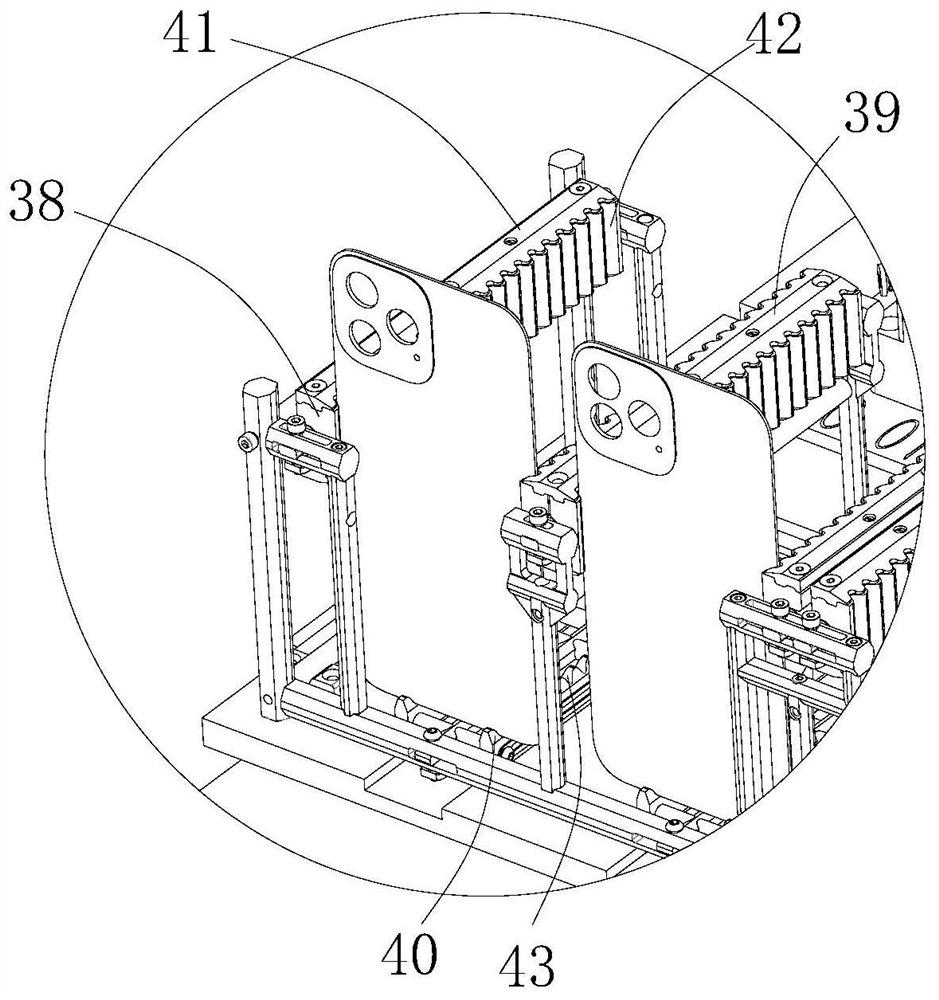

[0044] Such as Figure 1-6 As shown, a multi-axis machining center with automatic loading and unloading of the present invention includes a base 8, a gantry 9 in the X-axis direction is arranged above the base 8, a track in the Y-axis direction is provided below the base 8, and a The Y-axis traveling device that cooperates with the track, the gantry 9 includes a crossbeam 10 in the X-axis direction, and the front side of the crossbeam 10 is provided with an X-axis traveling device 11, and the X-axis traveling device 11 is provided with a first activity that moves along the X-axis direction. The part is connected with a Z-axis traveling device 12, and the second movable part that the Z-axis traveling device 12 is provided with moves along the Z-axis direction is connected with a machine head assembly 13, and the front side of the machine head assembly 13 is provided with a Z-axis drive cylinder 14, The movable end of the Z-axis drive cylinder 14 is provided with an X-axis drive...

Embodiment 2

[0049] Such as Figure 1-10 As shown, a multi-axis machining center with automatic loading and unloading of the present invention includes a base 8, a gantry 9 in the X-axis direction is arranged above the base 8, a track in the Y-axis direction is provided below the base 8, and a The Y-axis traveling device that cooperates with the track, the gantry 9 includes a crossbeam 10 in the X-axis direction, and the front side of the crossbeam 10 is provided with an X-axis traveling device 11, and the X-axis traveling device 11 is provided with a first activity that moves along the X-axis direction. The part is connected with a Z-axis traveling device 12, and the second movable part that the Z-axis traveling device 12 is provided with moves along the Z-axis direction is connected with a machine head assembly 13, and the front side of the machine head assembly 13 is provided with a Z-axis drive cylinder 14, The movable end of the Z-axis drive cylinder 14 is provided with an X-axis driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com