Automatic machining machine table for shell body of automobile suspension ball pin

A technology of automatic processing and hanging balls, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of driving safety, poor processing quality precision, and low work efficiency that affect the enterprise's benefits, and improve work efficiency and product quality, high degree of automation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

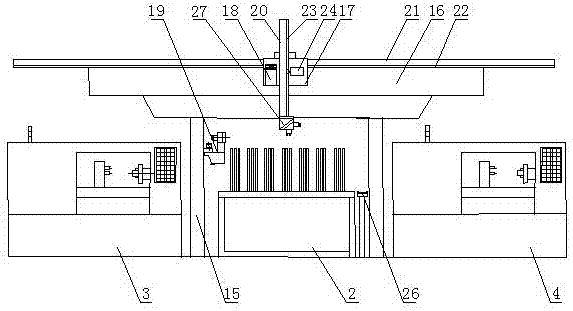

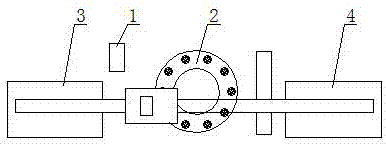

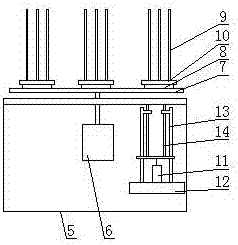

[0022] The automatic processing machine for the automobile suspension ball pin housing includes a program control cabinet 1, a feeding device 2, a feeding and clamping device, a machine tool A3 and a machine tool B4. The machine tool A3 and the machine tool B4 are symmetrically arranged side by side, and a feeding device 2 is installed between the machine tool A3 and the machine tool B4. The feeding device 2 comprises a feeding frame 5, an indexing motor 6, an indexing plate 7, a workpiece storage rack and a jacking device, and the indexing plate 7 is equipped with an indexing motor 6 on the working table of the feeding frame 5, A plurality of workpiece storage racks are evenly distributed on the circumference of the indexing plate 7 . The workpiece storage rack comprises a base 8, a storage rod 9 and a tray 10, the base 8 is triangularly equipped with a plurality of storage rods 9, and the storage rod 9 is slidably fitted with a tray 10. During work, a plurality of workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com