Mask surface folding equipment for mask production line

A folding equipment and production line technology, applied in the direction of folding thin materials, tools for sewing clothes, metal processing, etc., can solve the problems of complex structure and operation, slow flattening and shaping of masks, and inability to mass-produce, etc., to achieve simple structure, Fast flattening and shaping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

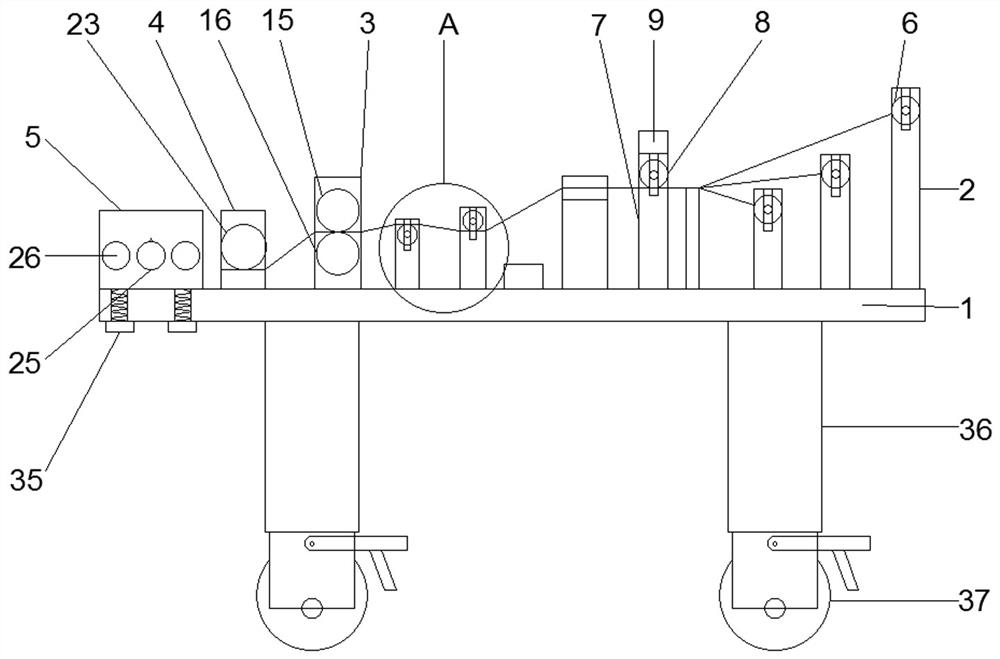

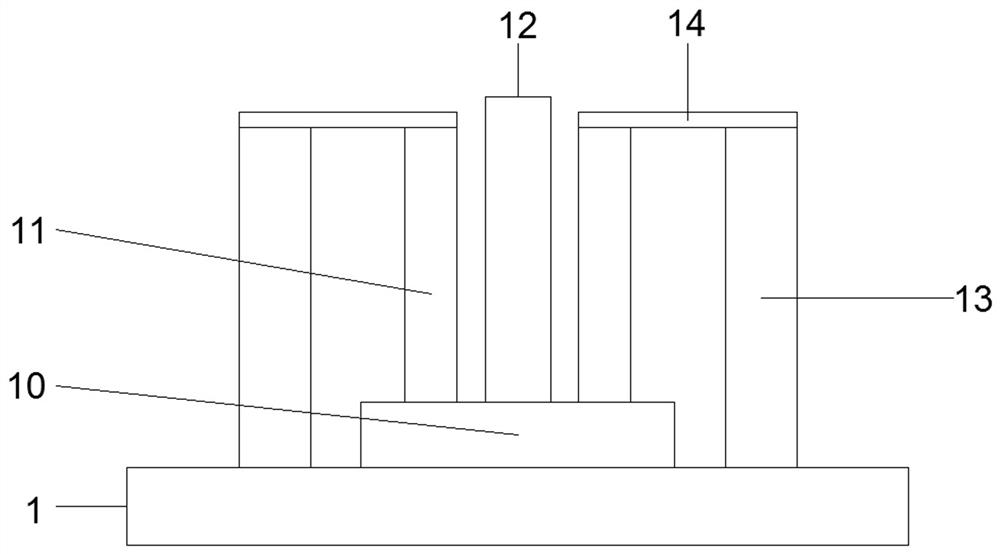

[0026] see Figure 1-5 According to an embodiment of the present invention, a mask face folding device for a mask production line includes a workbench 1, and the upper end of the workbench 1 is sequentially installed with a roller frame 2, a folding frame, a tensioning device, and a shaping wheel frame from left to right. 3. The driving frame 4 and the shearing frame 5. The upper end of the roller frame 2 is provided with three rollers 6 through the first rotating shaft. The folding frame includes a crease frame 7 and a crease deepening frame. A crease wheel 8 is arranged on the crease frame 7, and a first motor 9 is fixedly provided on one side of the crease wheel 8. The crease deepening frame includes a base 10, and the base 10 is fixed on the workbench 1. Both sides of the upper end of the base 10 are symmetrically fixed with a first support plate 11, the middle part of the upper end of the base 10 is fixed with a second support plate 12, and both sides of the base 10 are p...

Embodiment 2

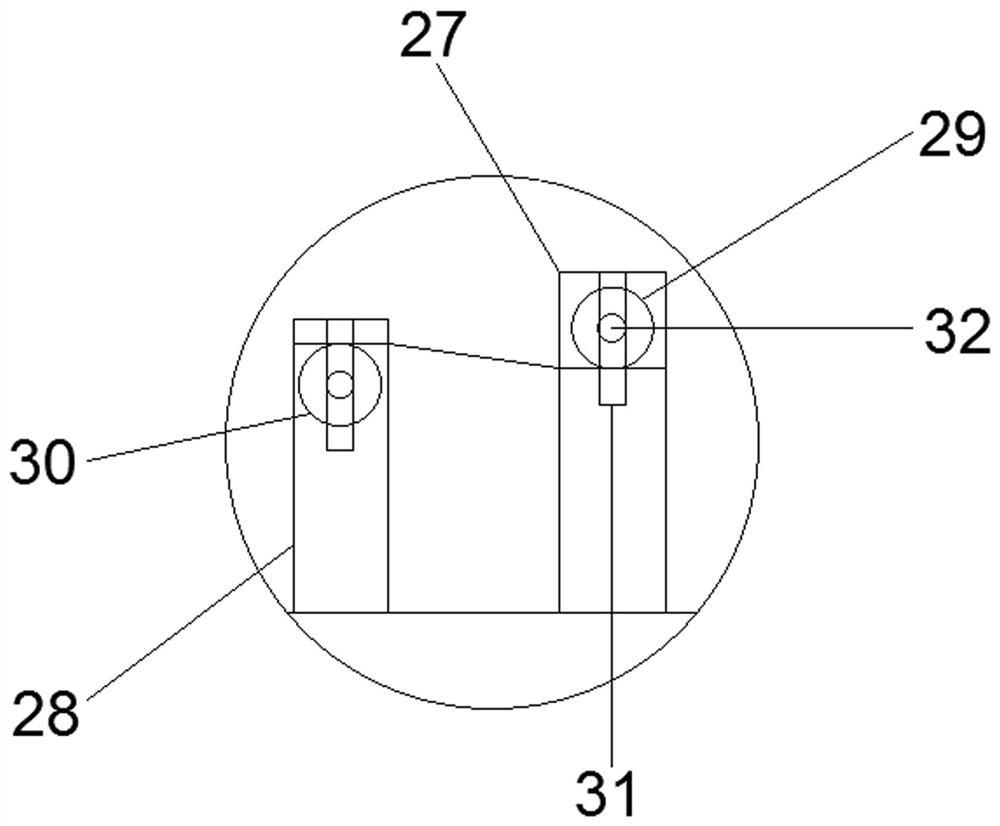

[0029] see figure 1 , image 3 and Figure 5 , for the first roller and the second roller, the tensioning device includes a high roller frame 27 and a low roller frame 28, and the high roller frame 27 and the low roller frame 28 are respectively arranged on the fourth rotating shaft There are first rollers 29 and second rollers 30. For U-shaped grooves and damping protrusions, there are U-shaped grooves 31 at the side of the roller frame 2, the folding frame and the tensioning device. One end of the first rotating shaft and the fourth rotating shaft are fixed with a damping protrusion 32 matching the U-shaped groove 31. For the bearing, the second rotating shaft and the third rotating shaft pass through the bearing 33 is arranged on the said sizing wheel frame 3, for the rolling protrusions, said damping roller 23 is fixedly provided with several rolling protrusions 34.

[0030] Through the above scheme of the present invention, the cloth can be supported and tightened, the...

Embodiment 3

[0032] see Figure 1-2 , for bolts, the level of the second support plate 12 is higher than that of the first support plate 1, the shear frame 5 is set on the workbench 1 by bolts 35, for the support rod, the work The four corners of the lower end of the table 1 are fixedly provided with support rods 36, and for universal wheels, the lower ends of the support rods 36 are fixedly provided with universal wheels 37.

[0033] Through the above solution of the present invention, the installation and replacement of the shear frame 5 can be facilitated, the workbench can be supported, and the movement of the workbench 1 can be facilitated.

[0034] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0035]In actual application, the first motor 9, the second motor 20 and the third motor 24 are turned on, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com