A kind of method for separating and recovering acrolein from the hydration product of 3-hydroxypropionaldehyde prepared by hydration of acrolein

A technology of hydroxypropionaldehyde and acrolein water, which is applied in the separation/purification of carbonyl compounds, sustainable manufacturing/processing, organic chemistry, etc. Large volume and other problems, to achieve the effect of long equipment operation cycle, high cooling efficiency and easier cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

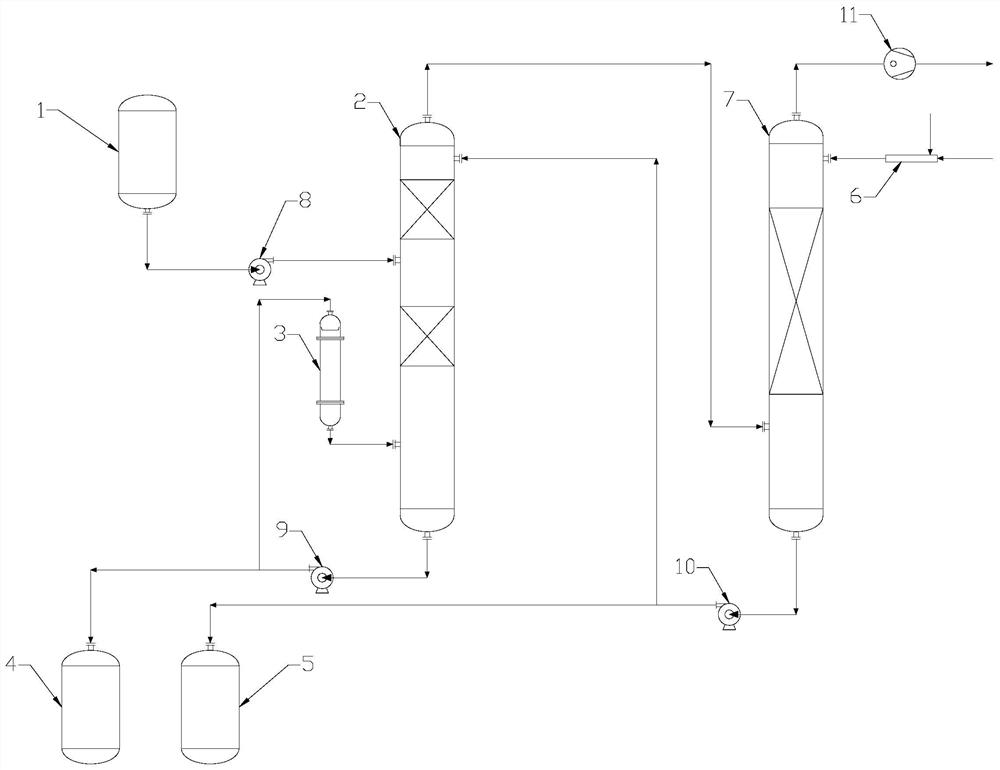

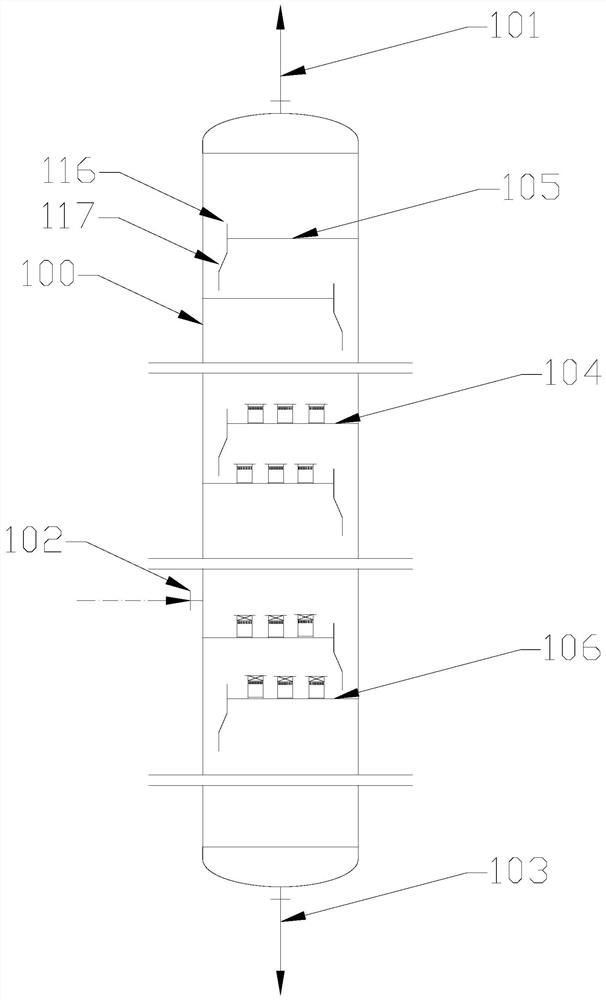

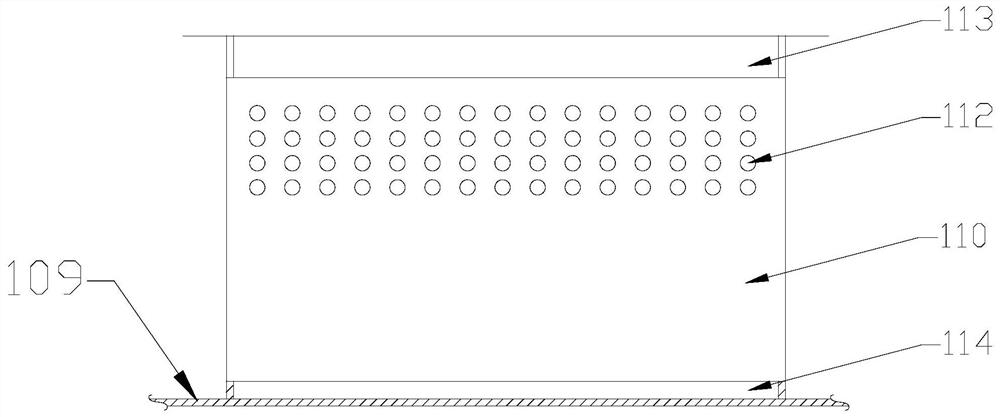

[0066] An acrolein separation device, comprising: a hydration liquid tank 1, an acrolein rectification tower 2, a falling film evaporator 3, a 3-hydroxypropanal product tank 4, an acrolein recovery tank 5, a static mixer 6 and acrolein Spray tower 7. Specifically, the hydration liquid tank is communicated with the middle section of the acrolein rectification tower (a feed pump 8 is provided on the pipeline), and the bottom of the acrolein rectification tower is connected to the 3-hydroxypropionaldehyde product tank and the falling film evaporator respectively. Connected (there is a tower bottom pump 9 on the pipeline), the falling film evaporator is connected with the middle section of the acrolein rectification tower, and the top of the acrolein rectification tower is connected with the body of the acrolein spray tower; the acrolein spray tower The top of the tower is provided with a non-condensable gas outlet, and a vacuum pump 11 is provided on the pipeline at the top of th...

Embodiment 2

[0075] The difference between this example and Example 1 is: the hydration liquid containing 4.5% (mass) of acrolein is pumped into the middle of the acrolein rectification tower from the hydration liquid tank through the feed pump, and the vacuum degree is -0.080~-0.075MPa, After the deacrolein treatment, the acrolein at the bottom of the tower was reduced to less than 500ppm. The solution was partially pumped into the 3-hydroxypropanal product tank through the bottom pump of the acrolein rectification tower to enter the subsequent reaction, and part of it entered the falling film evaporator. The ratio is 2:1~3:1 (mass), the outlet temperature of the evaporator is 57~65°C; the gas phase at the top of the tower enters the bottom of the acrolein spray tower, the height of the spray tower in the tower is 3m, and the top of the tower adopts 6~8 ℃ chilled water, the content of polymerization inhibitor is 1000ppm, the ratio of spray water to the feed of the acrolein rectifying tower...

Embodiment 3

[0077] The difference between this example and Example 1 is: the hydration liquid containing 3.5% (mass) of acrolein is pumped into the middle of the acrolein rectification tower from the hydration liquid tank through the feed pump, and the vacuum degree is -0.080~-0.075MPa, After the deacrolein treatment, the acrolein at the bottom of the tower was reduced to less than 500ppm. The solution was partially pumped into the 3-hydroxypropanal product tank through the bottom pump of the acrolein rectification tower to enter the subsequent reaction, and part of it entered the falling film evaporator. The ratio is 2:1~3:1 (mass), the outlet temperature of the evaporator is 57~65°C; the gas phase at the top of the tower enters the bottom of the acrolein spray tower, the height of the spray tower in the tower is 3m, and the top of the tower adopts 6~8 ℃ chilled water, the content of polymerization inhibitor is 1000ppm, the ratio of spray water to the feed of the acrolein rectifying tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap