Epoxy resin composition as well as preparation method and application thereof

A technology of epoxy resin and composition, which is applied in the field of epoxy resin composition and its preparation, can solve the problems of high price of carbon fiber, etc., and achieve the effects of great economic value and market prospect, long toughness and high reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

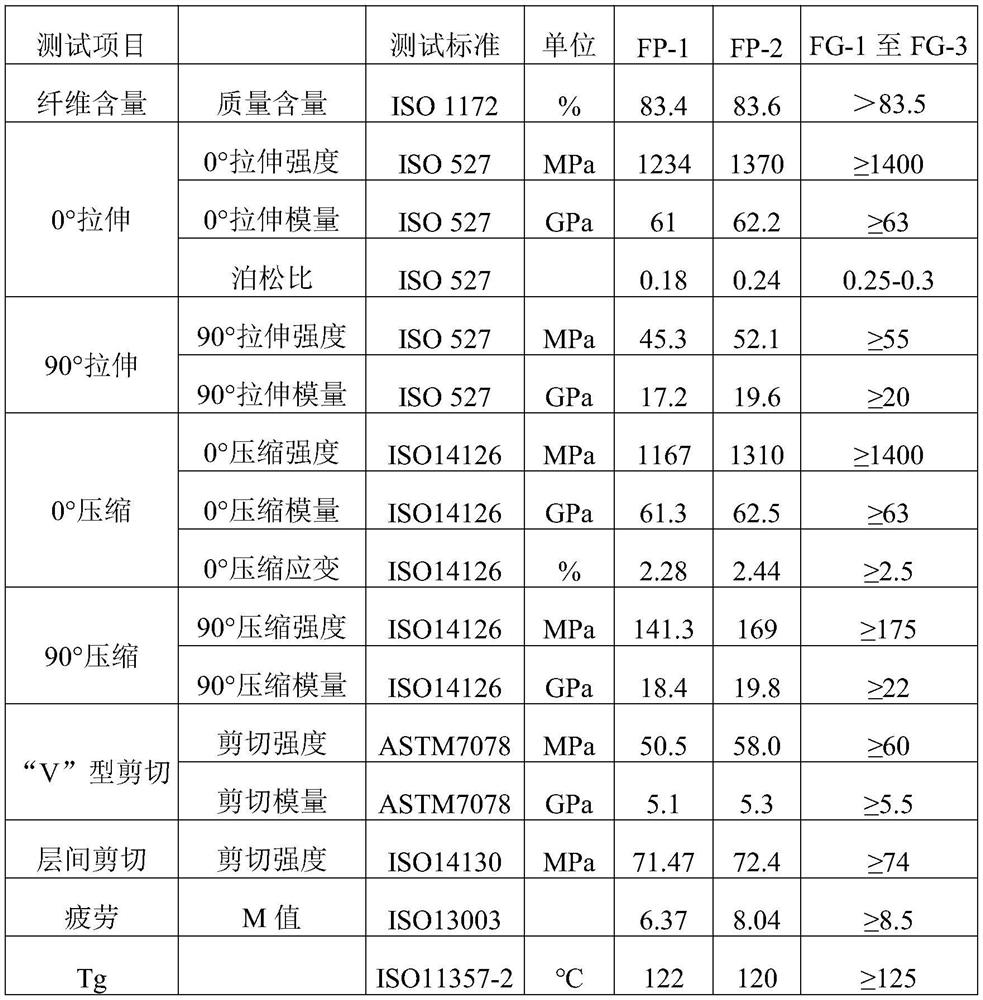

Image

Examples

Embodiment 1

[0029] The preparation process of epoxy resin composition of the present invention is as follows:

[0030] (1) Weigh 5 parts of toughening agent, 2 parts of release agent, 0.5 part of defoamer, 1 part of coupling agent, 2 parts of accelerator according to the parts by weight of each component in the additive (C), and stir for 20 minutes, Stand still for 30min, set aside;

[0031] (2) According to epoxy resin (A): acid anhydride curing agent (B): additive (C)=100: (80-100): (1-43) take by weighing 100 parts of South Asia E51 resins, join in the reactor, Control the temperature at 65°C, weigh 85 parts of tetrahydromethylphthalic anhydride and the additive (C) prepared in step 1, add them to the reaction kettle in turn, and keep stirring evenly to obtain an epoxy resin composition, which is named HB-1.

[0032] The epoxy resin composition prepared in this example had a gel time of 54s at 150°C, a reaction exothermic peak temperature of 140°C, an elongation at break of 5.6% at 25...

Embodiment 2

[0034] The preparation process of epoxy resin of the present invention is as follows:

[0035] (1) Weigh 5 parts of toughening agent, 2 parts of release agent, 0.5 part of defoamer, 1 part of coupling agent, 2 parts of accelerator according to the parts by weight of each component in the additive (C), and stir for 20 minutes, Stand still for 30min, set aside;

[0036] (2) According to epoxy resin (A): acid anhydride curing agent (B): additive (C)=100: (80-100): (1-43) take by weighing 100 parts of South Asia E51 resins, join in the reactor, Control the temperature at 65°C, weigh 90 parts of tetrahydromethylphthalic anhydride and the additive (C) prepared in step 1, add them to the reaction kettle in turn, and keep stirring evenly to obtain an epoxy resin composition, which is named HB-2.

[0037] The epoxy resin composition prepared in this example had a gel time of 50 s at 150°C, a reaction exothermic peak temperature of 138°C, an elongation at break of 5.8% at 25°C, and a v...

Embodiment 3

[0039] The preparation process of epoxy resin of the present invention is as follows:

[0040] (1) Weigh 10 parts of toughening agent, 2 parts of release agent, 0.5 part of defoamer, 1 part of coupling agent, 2 parts of accelerator according to the parts by weight of each component in the additive (C), and stir for 20 minutes, Stand still for 30min, set aside;

[0041] (2) According to epoxy resin (A): acid anhydride curing agent (B): additive (C)=100: (80-100): (1-43) take by weighing 100 parts of South Asia E51 resins, join in the reactor, Control the temperature at 65°C, weigh 85 parts of tetrahydromethylphthalic anhydride and the additive (C) prepared in step 1, add them to the reaction kettle in sequence, and keep stirring evenly to obtain an epoxy resin composition, which is named HB-3.

[0042] The epoxy resin composition prepared in this example had a gel time of 58s at 150°C, a reaction exothermic peak temperature of 141°C, an elongation at break of 6.2% at 25°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com