Stem cell culture method

A technology of stem cell culture and culture medium, applied in the field of stem cell culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

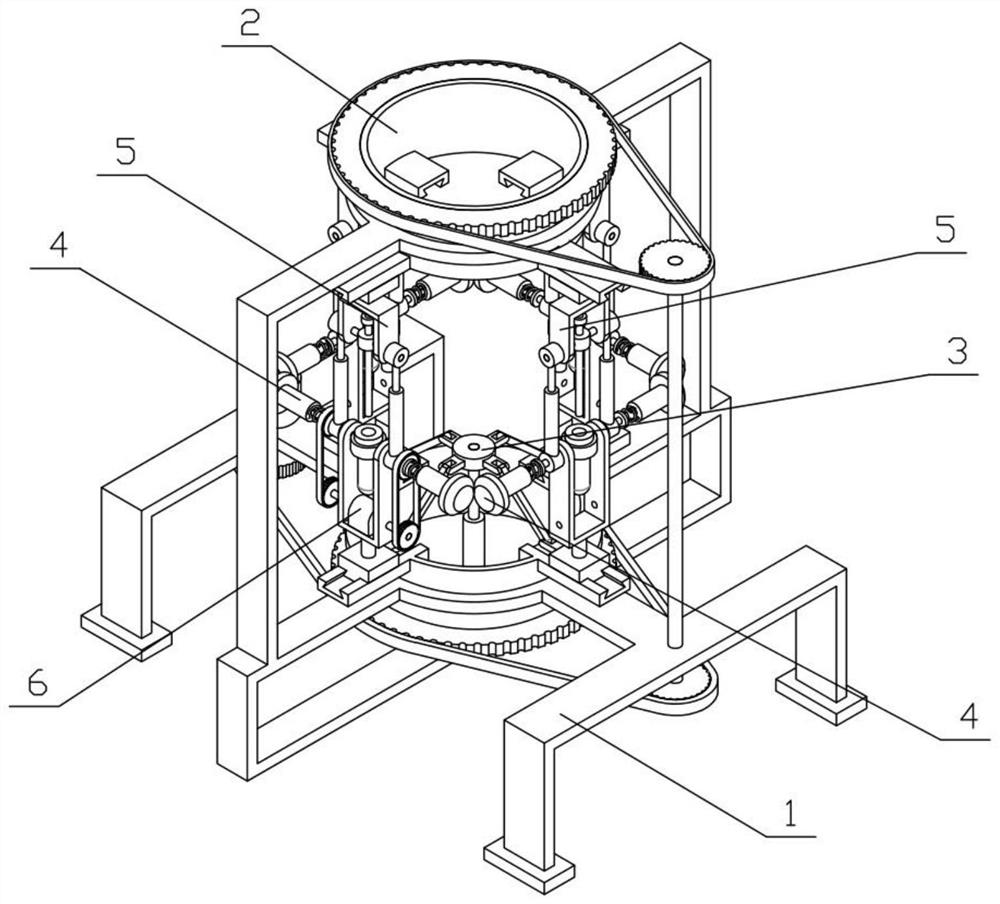

[0035] Combine below Figures 1 to 9 Describe this embodiment mode, a kind of stem cell culture method, this method comprises the following steps:

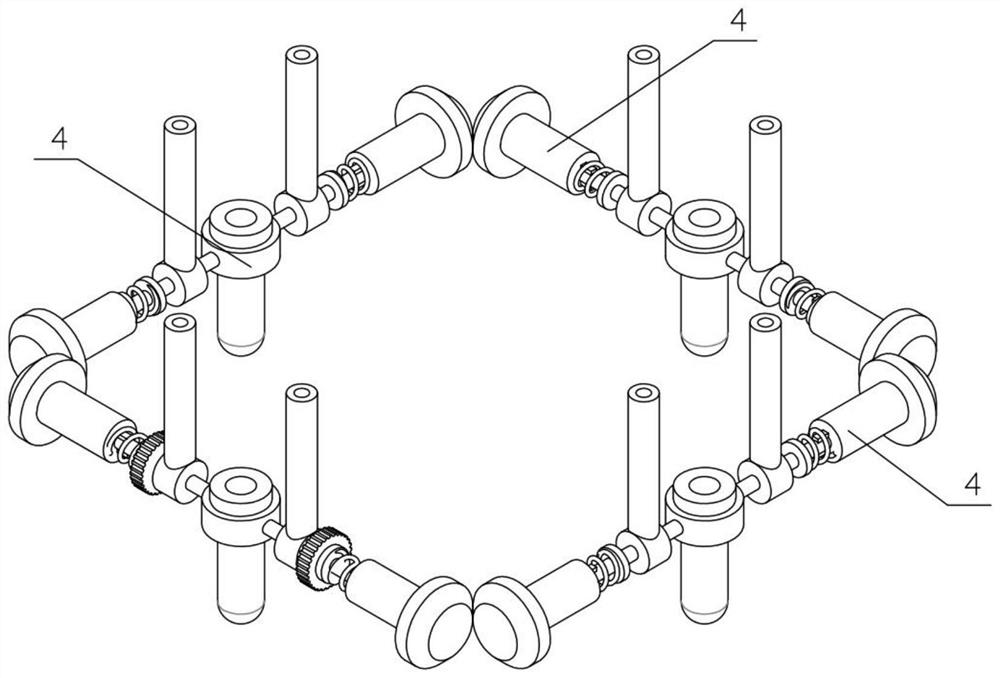

[0036] Step 1: placing a plurality of culture test tubes 408 filled with culture fluid on the centrifugal mechanism 4;

[0037] Step 2: the rotating mechanism 2 drives a plurality of centrifugal mechanisms 4 to rotate, and centrifugally stratifies the culture solution;

[0038] Step 3: multiple extracting mechanisms 5 respectively peel off the layered culture solutions in multiple culture test tubes 408;

[0039] The above-mentioned stem cell culture method also relates to a stem cell culture device. The stem cell culture device includes a device bracket 1, a rotating mechanism 2, a pushing mechanism 3, a centrifugal mechanism 4, an extracting mechanism 5 and an angle motor 6. The device bracket 1 is connected with a rotating mechanism 2. The pushing mechanism 3 is fixedly connected to the device bracket 1, and the pushing mecha...

specific Embodiment approach 2

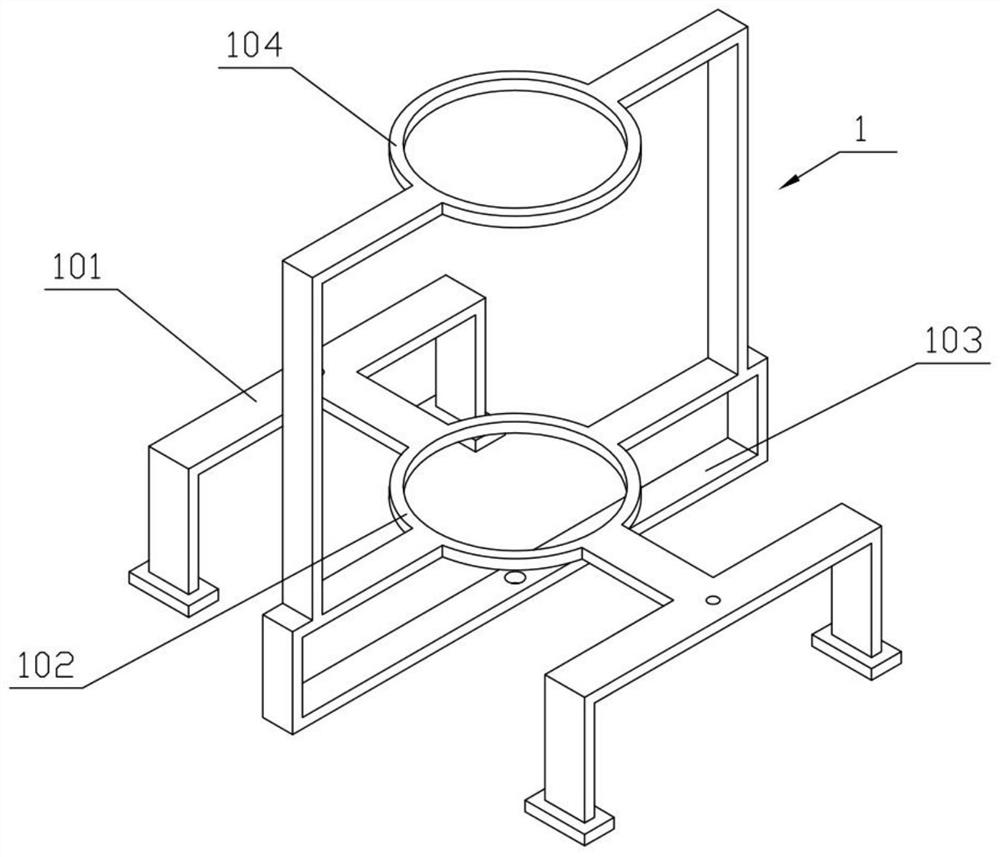

[0041] Combine below Figures 1 to 9Describe this embodiment, this embodiment will further explain Embodiment 1, the device bracket 1 includes a bottom bracket 101, a support ring I 102, an installation bracket 103 and a support ring II 104, the middle part of the bottom bracket 101 is fixedly connected with a support ring I 102, the bottom A mounting bracket 103 is fixedly connected to the bottom of the bracket 101 , and a supporting ring II 104 is fixedly connected to the upper end of the mounting bracket 103 .

specific Embodiment approach 3

[0043] Combine below Figures 1 to 9 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating mechanism 2 includes a rotating motor 201, a rotating cylinder I202, a rotating pulley I203, a slide rail I204, a transmission shaft 205, a rotating cylinder II206, a rotating pulley II207 and slide rail II208, the rotating motor 201 is fixedly connected to the bottom bracket 101, the rotating cylinder I202 is rotationally connected to the support ring I102, the rotating cylinder I202 is fixedly connected to the rotating pulley I203, the output of the rotating pulley I203 and the rotating motor 201 Shaft transmission connection, four sliding rails I204 are fixedly connected to the rotating cylinder I202, the transmission shaft 205 is rotationally connected to the bottom bracket 101, the transmission shaft 205 is connected to the rotating pulley I203, and the rotating cylinder II206 is rotationally connected to the supporting ring II104. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com