Well and lane engineering treatment method under complex engineering geological conditions

A technology based on engineering geology and conditions, applied in underground chambers, shaft linings, shaft equipment, etc., can solve problems such as water gushing in roadways, high cost, and roof collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

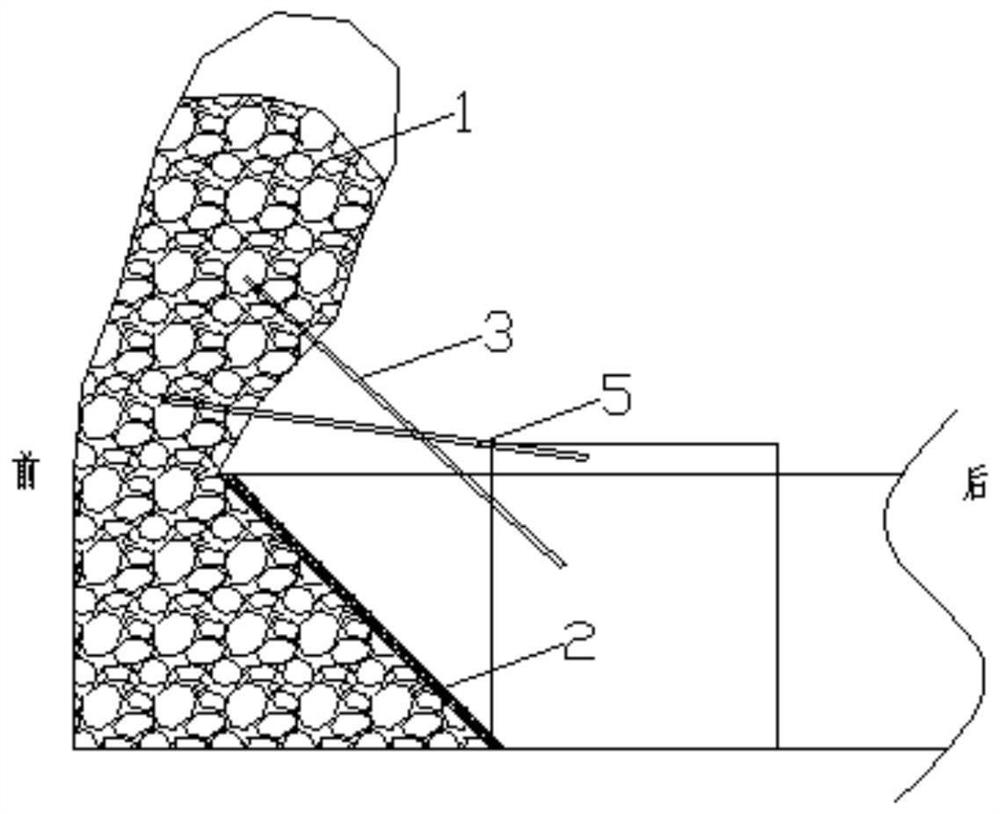

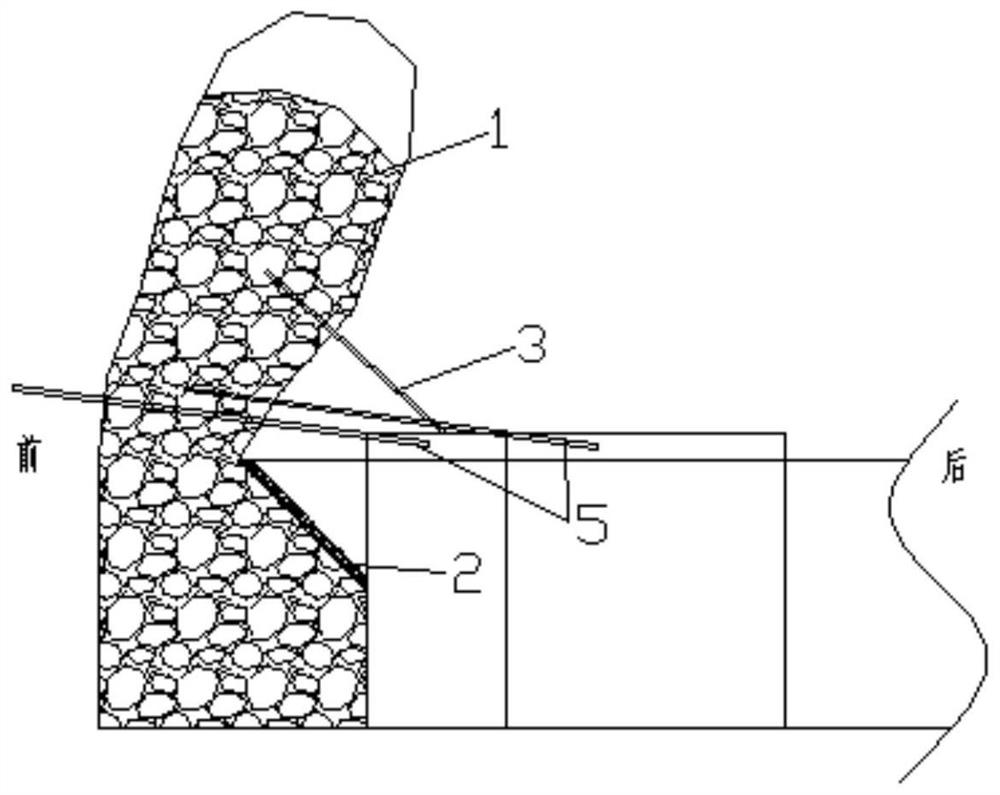

[0047] On the basis of the above structure, in this embodiment, step S2 specifically includes the following steps:

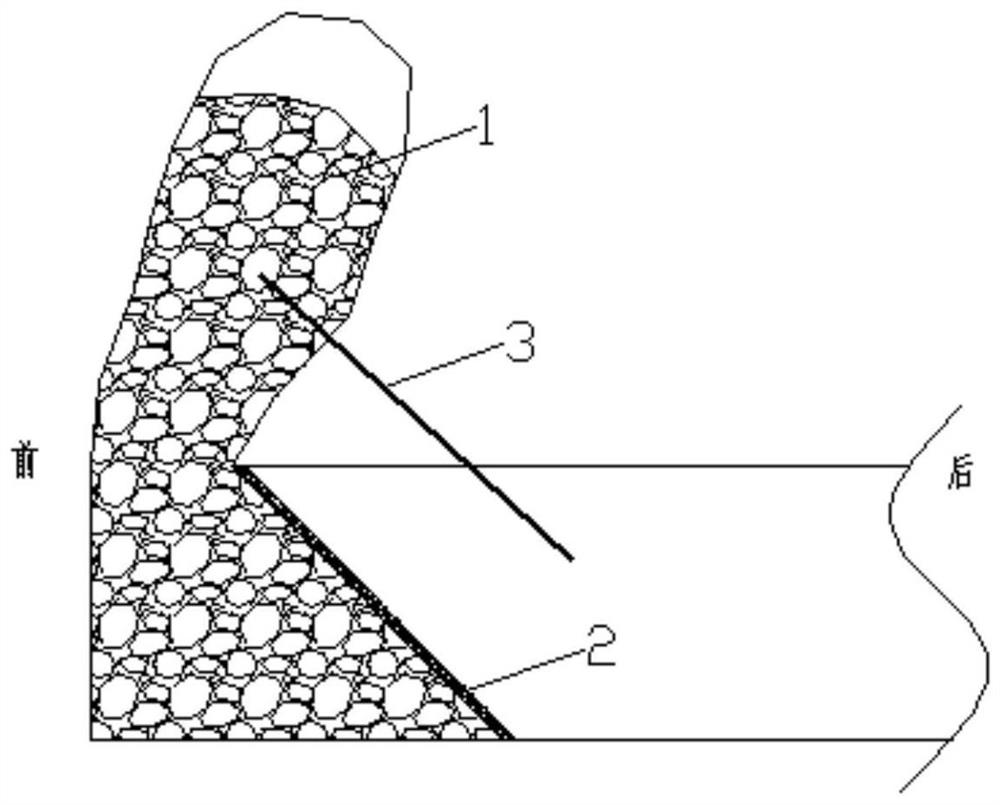

[0048] S21: Manually insert a plurality of grouting pipes 3 at intervals in the vertical direction on the upper part of the surface of the slag 1 that has collapsed in the roadway;

[0049] S22: Inject grout into a plurality of grouting pipes 3 in order from bottom to top. In two adjacent grouting pipes 3, when grouting occurs in the upper grouting pipe 3, the grouting pipe below will be grouted. The grouting pipe 3 is closed, and the grouting of the grouting pipe 3 above is started, and the grouting is performed sequentially.

[0050] In this embodiment, grout is injected into a plurality of grouting pipes 3 sequentially from bottom to top. In two adjacent grouting pipes 3, when grouting occurs in the upper grouting pipe 3, the grouting pipe 3 that is being grouted will be The lower grouting pipe 3 is closed, and the grouting of the upper grouting pipe 3 is st...

Embodiment 2

[0053] On the basis of Embodiment 1, in this embodiment, in step S21, three grouting pipes 3 are inserted into the upper part of the surface of the slag 1 that has collapsed in the roadway. The structure is simple and the design is reasonable, ensuring that all parts of the slag 1 are Filled with slurry, so as to ensure the stability of the slag 1 cementation.

[0054] Among them, when grouting and filling the collapsed part of the tunnel vault, single-liquid grouting is used, and the grouting pipe 3 is grouted in order from low to high, and the lower grouting pipe 3 is terminated according to the grouting situation of the upper grouting pipe 3 of grouting. Taking the three grouting pipes 3 as an example, the three grouting pipes 3 from top to bottom become the upper grouting pipe, the middle grouting pipe and the lower grouting pipe; When grouting occurs in the pipe, close the lower grouting pipe 3; then, grout into the middle grouting pipe; when grouting occurs in the upper...

Embodiment 3

[0058] On the basis of Embodiment 1, in this embodiment, one end of each grouting pipe 3 inserted into the slag 1 collapsed in the roadway is in the shape of a pointed cone, with a simple structure and reasonable design, which is convenient for quickly inserting the grouting pipe 3 into the slag. Within 1 stone, saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com