Submerged arc furnace for producing macrocrystalline fused magnesite

A technology of fused magnesia and submerged arc furnace, which is used in furnaces, crucible furnaces, waste heat treatment and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

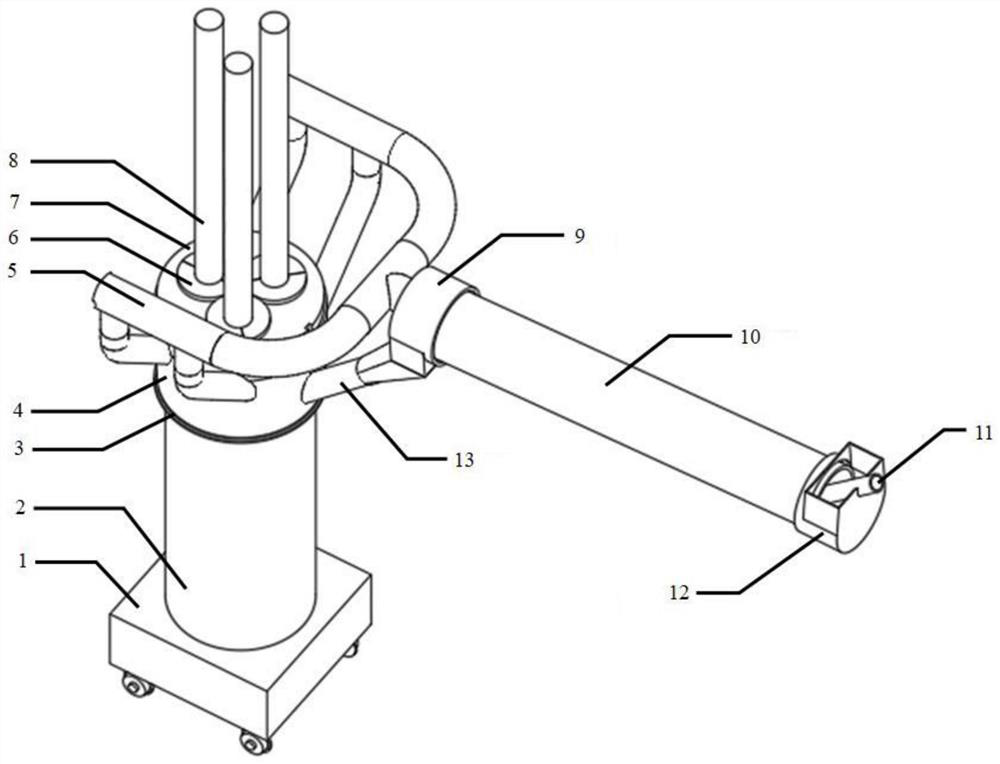

[0027] Such as figure 1 As shown, the submerged arc furnace for producing large crystal fused magnesia includes a furnace tube device, a feeding device and a smoke collection device, and the feed device and the smoke collection device are connected to the furnace cover of the furnace tube device, The feeding chute of the feeding device passes through the drying cylinder of the flue gas collecting device, and the material in the feeding chute is preheated by the flue gas in the drying cylinder.

[0028] The furnace tube device includes a trolley 1, a furnace body 2, a sealing gasket 3 and a furnace cover 4. The furnace body 2 is placed on the trolley 1, and a furnace cover 4 is arranged on the top of the furnace body 2. The lower part of the furnace cover 4 is There is a ceramic fiber sealing washer 3 between the furnace body 2 top to strengthen the sealing effect. The inner wall of the furnace cover 4 is provided with a refractory material layer, which plays the role of heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com