Stay wire displacement sensor with fault monitoring function, and use method thereof

A displacement sensor and fault monitoring technology, applied in the field of rope displacement sensors, can solve the problems of poor system operation reliability, closed-loop control, and inability to issue alarms in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

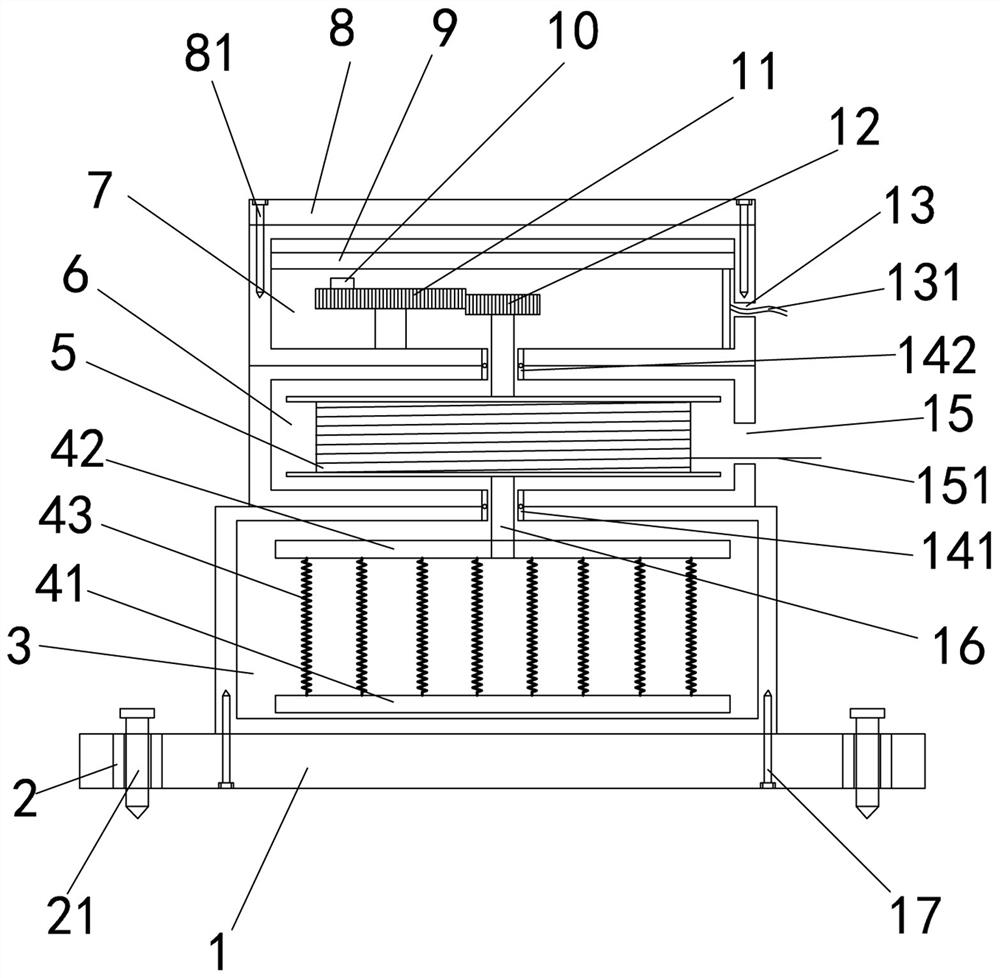

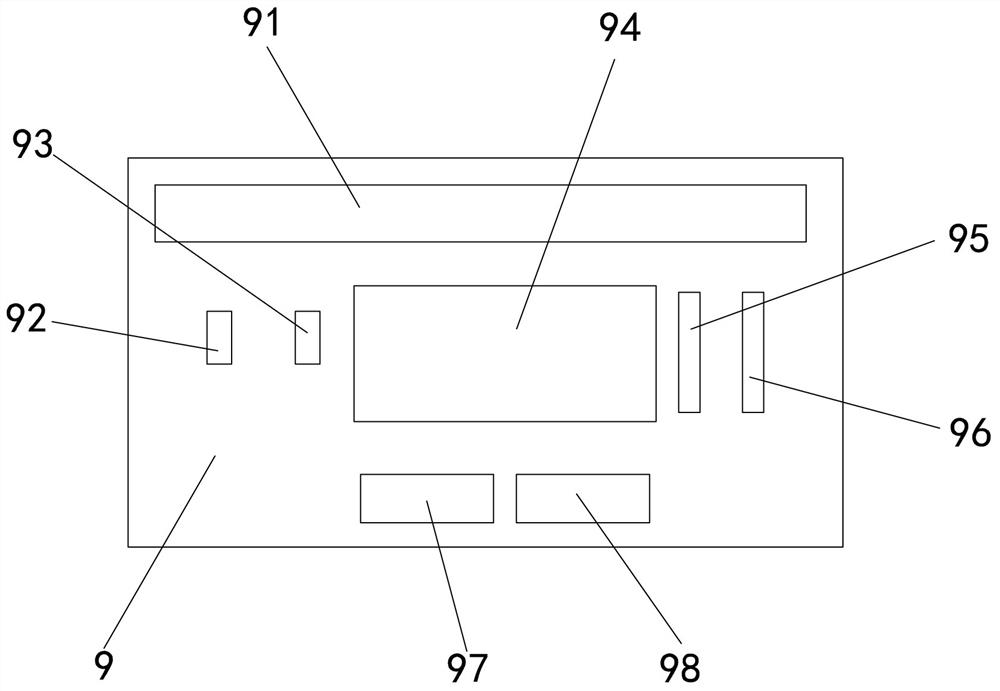

[0036] Embodiment one: if figure 1 , 2As shown, it is only one of the embodiments of the present invention, a cable displacement sensor with fault monitoring function, including a base plate 1, a spring chamber 3 arranged on the base plate 1, a spring chamber arranged on the spring chamber 3 The dragon hub chamber 6, the detection chamber 7 disposed on the dragon hub chamber 6 and the cover plate 8 disposed on the detection chamber 7, the dragon hub chamber 6 is provided with a dragon hub 5 wound with a pull wire 151 , the side wall of the dragon hub cavity 6 is provided with a cable hole 15 for facilitating the passage of the cable 151, the dragon hub 5 is connected with a central shaft 16, and the connection between the spring cavity 3 and the dragon hub cavity 6 is provided with a hole for It is convenient to fix the first bearing 141 of the central shaft 16, the connection between the hub chamber 6 and the detection chamber 7 is provided with a second bearing 142 for conv...

Embodiment 2

[0052] Embodiment two, still as figure 1 , 2 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a cable displacement sensor with fault monitoring function of the present invention, the number of the spring 43 is at least one, ensuring that the first plate 41 and the connection stability between the second board 42.

[0053] In addition, the bottom plate 1 is provided with a mounting hole 2 , a mounting bolt 21 for passing through the mounting hole 2 , and a first connecting bolt 17 for connecting the bottom plate 1 and the spring chamber 3 . The installation bolts 21 pass through the installation holes 2 to install the floor 1 on the ground (or the device to be used), and before that, the bottom plate 1 is connected to the spring chamber 3 through the first connection bolt 17 .

[0054] Here, the number of the installation hole 2 , the installation bolt 21 and the first connection bolt 17 is at least one. The stability of ...

Embodiment 3

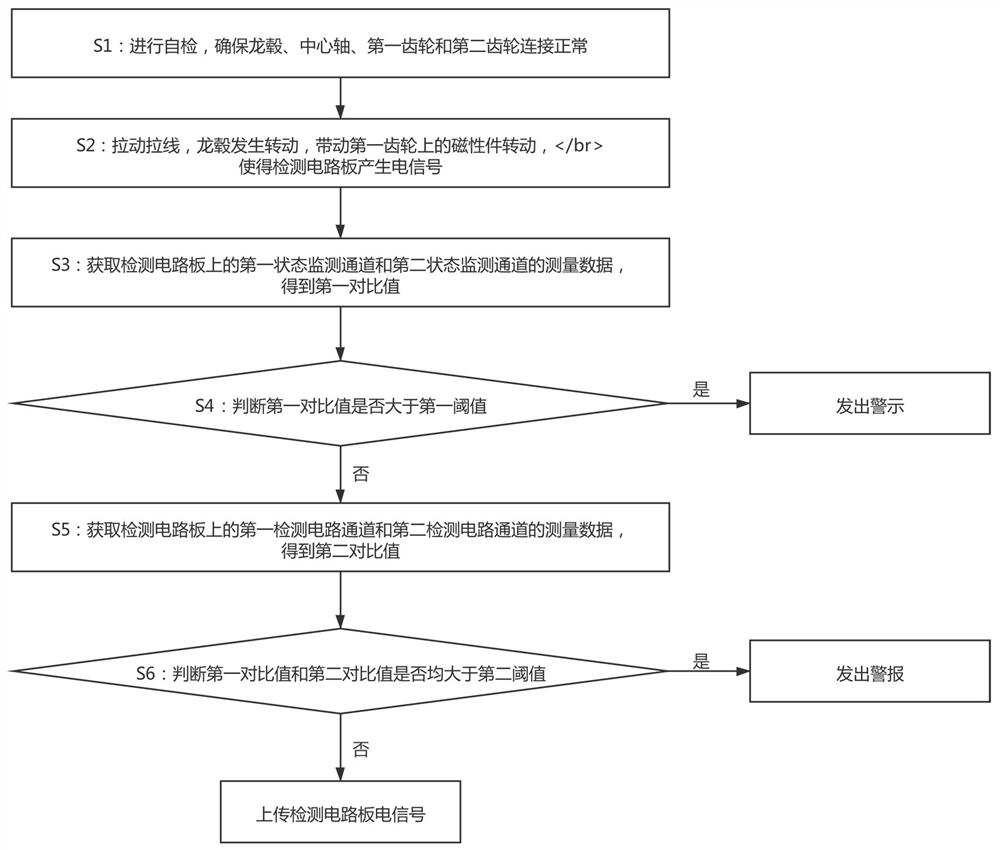

[0057] Embodiment three, such as image 3 As shown, the present invention also provides a method for using a cable displacement sensor with a fault monitoring function in all the above-mentioned embodiments, including the following steps:

[0058] S1: Carry out self-inspection to ensure that the connection between the dragon hub, the central shaft, the first gear and the second gear is normal;

[0059] S2: Pull the pull wire, the dragon hub rotates, and drives the magnetic part on the first gear to rotate, so that the detection circuit board generates an electrical signal;

[0060] S3: Obtain the measurement data of the first state monitoring channel and the second state monitoring channel on the detection circuit board to obtain a first comparison value;

[0061]S4: Determine whether the first comparison value is greater than the first threshold, and if so, issue a warning; otherwise, execute step S5;

[0062] S5: Obtain the measurement data of the first detection circuit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com